Accelerating agent for printing ink

A printing ink and quick-setting agent technology, applied in the printing field, can solve the problems of increasing air pollution, human injury, and human harm, and achieve the effect of green and safe raw materials, good quick-setting performance, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

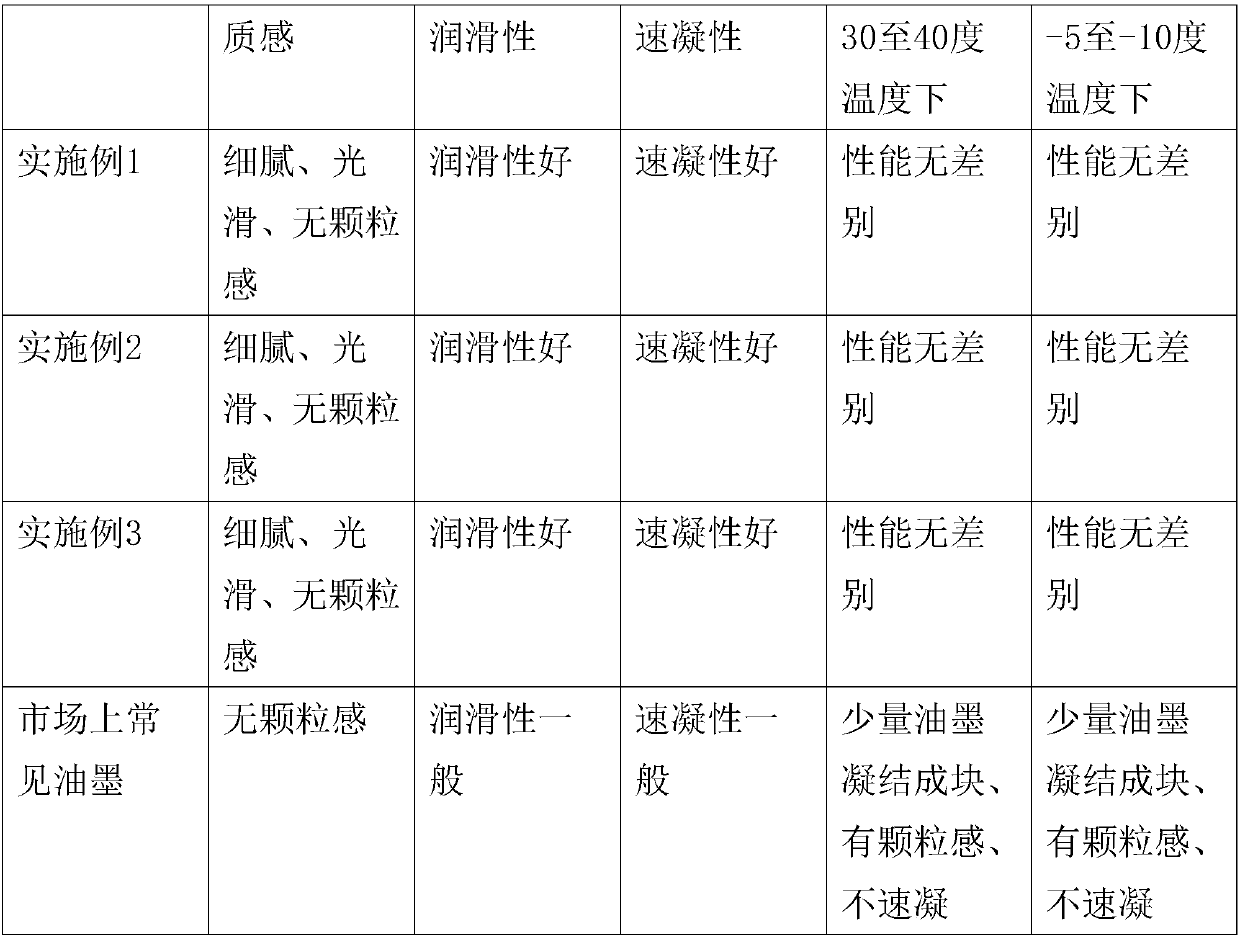

Examples

Embodiment 1

[0020] An accelerator for printing ink, made of the following components in parts by weight: 20 parts of aluminum hydroxide, 5 parts of calcium sulfate, 3 parts of cationic polyacrylamide, 4 parts of polyglutamic acid, 4 parts of graphite 4 parts of beeswax, 6 parts of paraffin wax, 6 parts of mica powder, 3 parts of talcum powder, 2 parts of defoamer, 2 parts of corn starch, 3 parts of bamboo charcoal fiber, and 1 part of modifier.

[0021] The improving agent is made of the following components in parts by weight: 3 parts of asbestos powder, 2 parts of table salt, 1 part of white vinegar, 5 parts of alcohol, 1 part of vitamin C, 1 part of vitamin E, 3 parts of egg white, and 1 part of egg yolk.

[0022] The above-mentioned preparation method of quick-setting agent for printing ink comprises the following steps:

[0023] a. Add aluminum hydroxide, calcium sulfate, cationic polyacrylamide, and polyglutamic acid into the reaction kettle, heat to a molten state, and keep stirrin...

Embodiment 2

[0030] An accelerator for printing ink, made of the following components in parts by weight: 30 parts of aluminum hydroxide, 10 parts of calcium sulfate, 6 parts of cationic polyacrylamide, 8 parts of polyglutamic acid, and 8 parts of graphite 6 parts, 6 parts of beeswax, 8 parts of paraffin wax, 8 parts of mica powder, 5 parts of talcum powder, 4 parts of defoamer, 4 parts of corn starch, 5 parts of bamboo charcoal fiber, and 3 parts of modifier.

[0031] The improving agent is made of the following components in parts by weight: 5 parts of asbestos powder, 4 parts of table salt, 2 parts of white vinegar, 10 parts of alcohol, 3 parts of vitamin C, 3 parts of vitamin E, 5 parts of egg white, and 3 parts of egg yolk.

[0032] The above-mentioned preparation method of quick-setting agent for printing ink comprises the following steps:

[0033] a. Add aluminum hydroxide, calcium sulfate, cationic polyacrylamide, and polyglutamic acid into the reaction kettle, heat to a molten sta...

Embodiment 3

[0040] An accelerator for printing ink, made of the following components in parts by weight: 25 parts of aluminum hydroxide, 8 parts of calcium sulfate, 5 parts of cationic polyacrylamide, 6 parts of polyglutamic acid, 6 parts of graphite 5 parts, 5 parts of beeswax, 7 parts of paraffin wax, 7 parts of mica powder, 4 parts of talcum powder, 3 parts of defoamer, 3 parts of corn starch, 4 parts of bamboo charcoal fiber, and 2 parts of modifier.

[0041] The improvement agent is preferably made of the following components in parts by weight: 4 parts of asbestos powder, 3 parts of table salt, 1.5 parts of white vinegar, 1.5 parts of alcohol, 1 part of vitamin C, 1 part of vitamin E, 2 parts of egg white, and 2 parts of egg yolk.

[0042] The above-mentioned preparation method of quick-setting agent for printing ink comprises the following steps:

[0043] a. Add aluminum hydroxide, calcium sulfate, cationic polyacrylamide, and polyglutamic acid into the reaction kettle, heat to a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com