High-performance alkali-free liquid accelerator and preparation method thereof

An accelerator and high-performance technology, which is applied in the field of high-performance alkali-free liquid accelerator and its preparation, can solve the problems of mechanical properties, large loss of durability, reduced synthesis reaction efficiency, and affecting the performance of accelerators, etc., to achieve Effects of improving early strength, improving stability, and improving cement adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

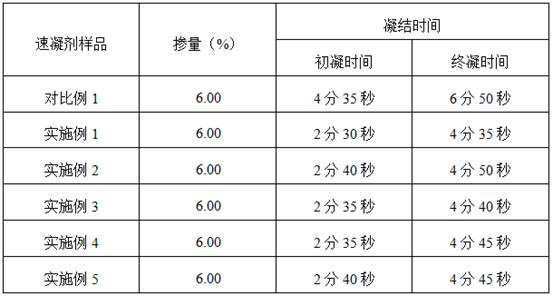

Examples

Embodiment 1

[0036] This embodiment includes the following steps:

[0037] (1) Preparation of activated aluminum hydroxide: take 1125g of aluminum nitrate nonahydrate aqueous solution as the bottom water and place it in a constant temperature water bath at 40°C for reaction, and simultaneously add 1140g of ammonia water (20%) and 40g of ethylenediaminetetraacetic acid disodium aqueous solution dropwise , Filtration, the resulting precipitate is activated aluminum hydroxide.

[0038] (2) Preparation of fluoroaluminum complex: Add 150.00g of 40% concentration hydrofluoric acid and bottom water into the reactor, turn on the stirring device, control the temperature of the reactor to 55°C, and then add 78.00g of hydrogen hydroxide in two Aluminum, heat preservation reaction for 2 hours to generate fluoroaluminum complex.

[0039] (3) Preparation of quick-setting agent: with 240.00g active aluminum hydroxide, 40.00g calcium fluoride, 25.00g triethanolamine, add in the fluoroaluminum complex rea...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] (1) Preparation of activated aluminum hydroxide: take 1125g of aluminum nitrate nonahydrate aqueous solution as the bottom water and place it in a constant temperature water bath at 40°C for reaction, and simultaneously add 1140g of ammonia water (20%) and 45g of disodium ethylenediaminetetraacetic acid aqueous solution dropwise , Filtration, the resulting precipitate is activated aluminum hydroxide.

[0045] (2) Preparation of fluoroaluminum complex: Add 175.00g of 40% concentration hydrofluoric acid and bottom water into the reactor, turn on the stirring device, control the temperature of the reactor to 60°C, and then add 78.00g of hydrogen hydroxide in two times Aluminum, heat preservation reaction for 3 hours to generate fluoro-aluminum complex.

[0046] (3) Preparation of quick-setting agent: 230.00g active aluminum hydroxide, 40.00g magnesium carbonate, 30.00g triisopropanolamine are added in the fluoroalumin...

Embodiment 3

[0050] The present embodiment comprises the following steps:

[0051] (1) Preparation of activated aluminum hydroxide: take 1140g of aluminum nitrate nonahydrate aqueous solution as the base water and place it in a constant temperature water bath at 40°C for reaction, and simultaneously add 1140g of ammonia water (20%) and 50g of disodium ethylenediaminetetraacetic acid aqueous solution dropwise , Filtration, the resulting precipitate is activated aluminum hydroxide.

[0052] (2) Preparation of fluoroaluminum complex: Add 150.00g of 40% concentration hydrofluoric acid and bottom water into the reactor, turn on the stirring device, control the temperature of the reactor to 60°C, and then add 75.00g of hydrogen hydroxide in two Aluminum, heat preservation reaction for 2.5 hours to generate fluoroaluminum complex.

[0053] (3) Preparation of quick-setting agent: With 235.00g active aluminum hydroxide, 35.00g magnesium sulfate, 30.00g diethanolamine, add in the fluoroaluminum com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com