A kind of PVB intermediate film of infrared cutoff and preparation method

An interlayer, ultraviolet technology, applied in the field of polymer and nanoparticle composite materials, can solve problems such as shortage and gap supply, and achieve the effects of improved transparency, reduced number of spherulites, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of embodiment 1PVB interlayer film

[0032] 1. Weigh each component by weight and set aside;

[0033] 2. Preparation of nano-scale heat-insulating particle slurry: add metal oxides to distilled water, seal and sonicate for 8-9 minutes to form a pre-dispersion; then put the pre-dispersion on a nano-sand mill for 2-3 hours, Heat-insulating particles with a particle size of ≤25nm are prepared for use; the metal oxide is a mixture of GTO and ATO, and the weight ratio of GTO and ATO is 3:1;

[0034] 2. Coarse material preparation: dissolve the organic ultraviolet absorber and antioxidant in the plasticizer to form a mixed solution, and add modification additives to the mixed solution; then put it into a twin-screw extruder, and then use a metering pump The nano-scale heat-insulating particle slurry prepared in step 2 is directly injected into the barrel of the extruder, extruded and mixed with PVB resin powder evenly, and the excess water vapor is suc...

Embodiment 2

[0038] PVB resin powder 100Kg, dialkyl oxalate 25Kg, dioctadecyl alcohol pentaerythiphosphite 0.3Kg, 2-(2'-hydroxy-3',5'-di-tert-butylphenyl) - 0.6Kg of 5-chlorobenzotriazole, 0.8Kg of nano-scale thermal insulation particle slurry, and 1.5Kg of citric acid, wherein the number average molecular weight of the PVB resin powder is 150,000. The nano-scale heat-insulating particle slurry is a mixture of GTO nano-powder and ATO nano-powder dispersed in a dispersant, the weight ratio of the nano-scale heat-insulating particle to the dispersant is 1:2, and the GTO nano-powder The weight ratio to ATO nanopowder is 3:1, the particle size is ≤25nm, and the dispersant is distilled water.

Embodiment 3

[0040] PVB resin powder 100Kg, dialkyl oxalate 25Kg, dioctadecyl alcohol pentaerythiphosphite 0.3Kg, 2-(2'-hydroxy-3',5'-di-tert-butylphenyl) - 0.6Kg of 5-chlorobenzotriazole, 0.8Kg of nanoscale thermal insulation particle slurry, wherein the number average molecular weight of the PVB resin powder is 150,000. The nano-scale heat-insulating particle slurry is a mixture of GTO nano-powder and ATO nano-powder dispersed in a dispersant, the weight ratio of the nano-scale heat-insulating particle to the dispersant is: 1:2, the GTO nano The weight ratio of the powder to the ATO nano powder is 3:1, the particle size is ≤25nm, and the dispersant is distilled water.

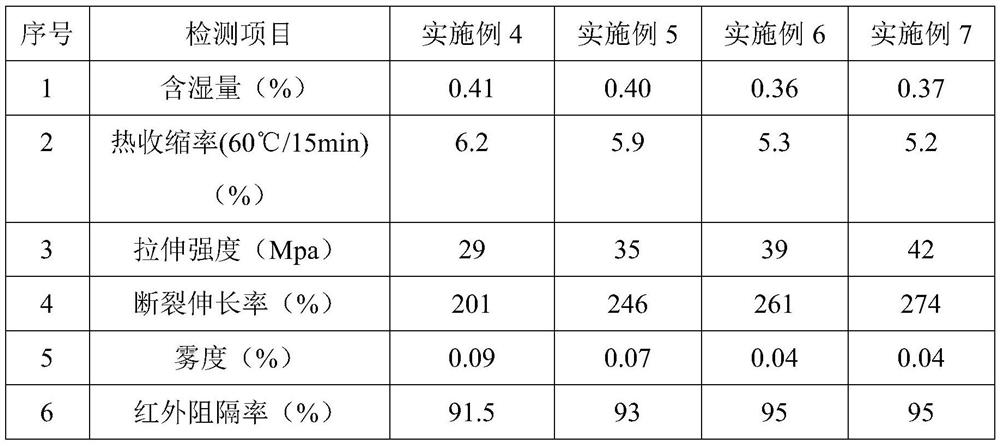

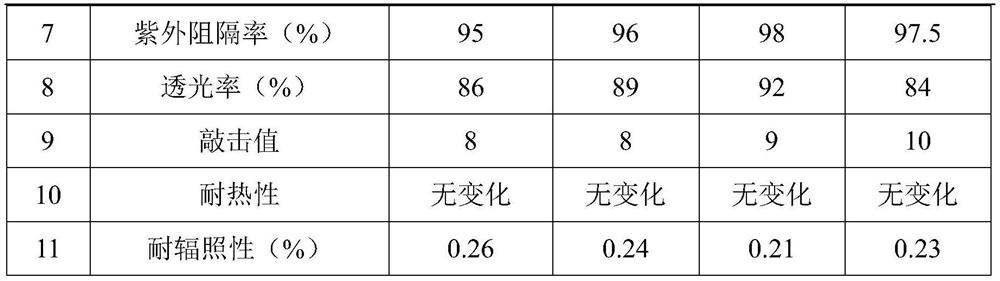

[0041] Perform performance testing on the PVB interlayer of Example 2-3, according to national standards GB / T2680-1994, GB / T6627-200, GB / T1040.3-2006, GB / T2410-2008, etc., and routine detection of PVB in this field The method of interlayer film is tested, and test result is as shown in table 1:

[0042] Table 1:

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com