High-efficiency setting accelerator

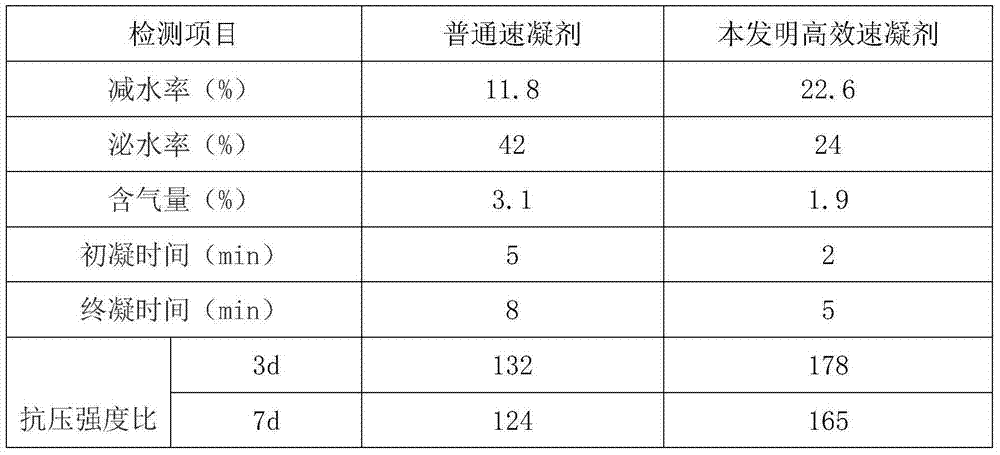

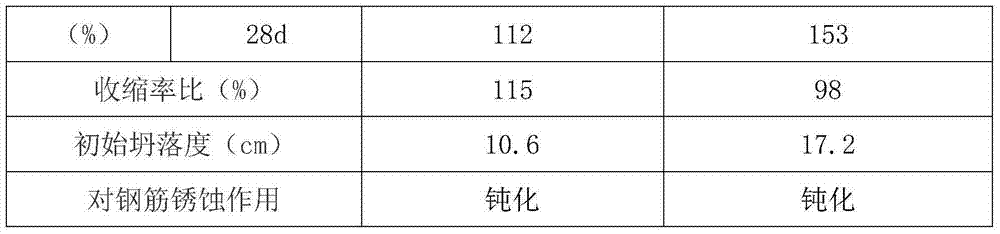

An accelerator and high-efficiency technology, applied in the field of high-efficiency accelerators, can solve the problems of poor quick-setting effect, inability to achieve rapid setting of emergency repair concrete, long setting time, etc., achieve small construction water consumption, good quick-setting effect, shorten The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A high-efficiency accelerator, which is made by mixing the following raw materials in weight (kg): alum mud 25, sodium aluminate 12, manganese naphthenate 3, 1,4-butynediol 8, HSA amino high-performance water reducing agent Agent 20, polydiallyl dimethyl ammonium chloride 16, polysilicate ferric sulfate 12, SN-Ⅱ superplasticizer 33, dialkyl zinc dithiophosphate 3.5, ethyl cyanoacrylate 5, modified Soybean lecithin 7, quicklime 12, sodium borate stone powder 11, carbomer 8, diethylene glycol dioleate 6, additive 4.5;

[0011] The auxiliary agent is made of the following raw materials by weight (kg): graphene oxide 18, tree ash 12, waste clay brick powder 10, octadecylamine 6, sodium cumene sulfonate 4, cryolite powder 12, polyester Rubber powder 8, fatty alcohol polyether amide 4, octyl dodecyl glucoside 3, isooctanyl phosphate 5, crystalline aluminum chloride 8, konjac flour 6, isopropyl tri(dioctyl pyrophosphate acyloxy base) titanate 1, sodium alginate 4;

[0012] M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com