Mineral additive for shotcrete as well as preparation method and application of mineral additive

A technology of shotcrete and mineral additives, which is applied in the construction of buildings, construction, and the treatment of building materials, etc., can solve problems such as increasing the cost of wet shotcrete, and achieve the effects of solving common problems, improving durability and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

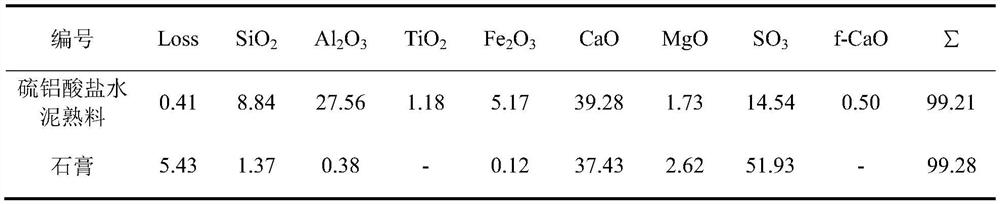

[0035] In terms of weight percentage, 75% of sulphoaluminate cement clinker and 25% of gypsum (chemical composition as shown in the table below) are co-ground to a specific surface area of 600m 2 / kg to get the shotcrete mineral additive.

[0036]

[0037] The liquid quick-setting agent includes the following components in weight percentage: 50% of aluminum sulfate, and the rest is water. Take aluminum sulfate in proportion and dissolve it in water in proportion to obtain liquid quick-setting agent.

[0038] Stir the sprayed concrete mineral additive with 20% of the mass of water to form a slurry evenly, then use the slurry metering pump to add 0.5% of the concrete mass to the concrete feed hopper of the wet spraying machine, and use a spraying device to uniformly Spray on the concrete; the liquid quick-setting agent is transported to the spray gun head of the wet spray machine according to 0.6% of the concrete mass by a liquid metering pump, mixed with the concrete adde...

Embodiment 2

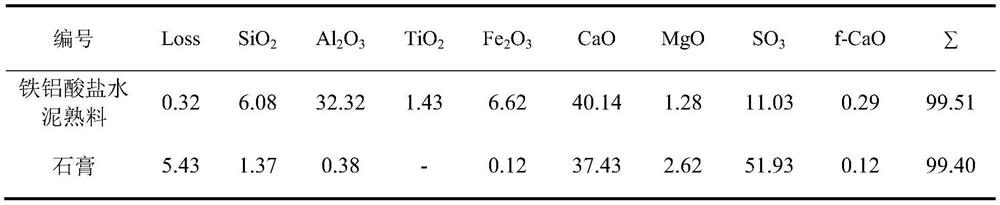

[0040] In terms of weight percentage, 60% of aluminate cement clinker and 35% of gypsum (chemical composition as shown in the table below), externally mixed with 2% of sodium lignosulfonate, 2% of sodium carbonate, and 1% of boric acid, together Grinding to a specific surface area of 500m 2 / kg to get the shotcrete mineral additive.

[0041]

[0042] The liquid quick-setting agent comprises the following components in weight percentage: 40% of aluminum sulfate, 1% of lithium carbonate, and the rest is water. Take aluminum sulfate and lithium carbonate in proportion respectively, and dissolve them in water in proportion to obtain a liquid quick-setting agent.

[0043] Stir the sprayed concrete mineral additive with 30% of the mass of water to form a slurry evenly, then use the slurry metering pump to add 4.0% of the concrete mass to the concrete feed hopper of the wet spraying machine, and use a spraying device to uniformly Spray on the concrete; the liquid quick-setting...

Embodiment 3

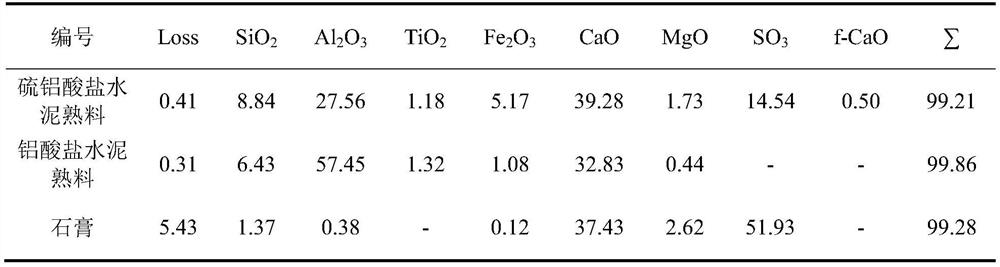

[0045] In terms of weight percentage, 50% of sulphoaluminate cement clinker, 40% of aluminate cement clinker and 10% of gypsum (chemical composition as shown in the table below) are jointly ground to a specific surface area of 400m 2 / kg to get the shotcrete mineral additive.

[0046]

[0047] The liquid quick-setting agent comprises the following components in weight percentage: 40% of aluminum sulfate, 1% of lithium carbonate, 1% of zinc carbonate, and the rest is water. Take aluminum sulfate, lithium carbonate, and zinc carbonate in proportion, and dissolve them in water in proportion to obtain a liquid quick-setting agent.

[0048] Stir the sprayed concrete mineral additive with 25% of the mass of water to form a slurry evenly, then use the slurry metering pump to add 3.0% of the concrete mass to the concrete feed hopper of the wet spraying machine, and use a spraying device to uniformly Spray on the concrete; the liquid quick-setting agent is transported to the spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com