Preparation method of pachyman sulfate

A kind of Poria polysaccharide, sulfate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

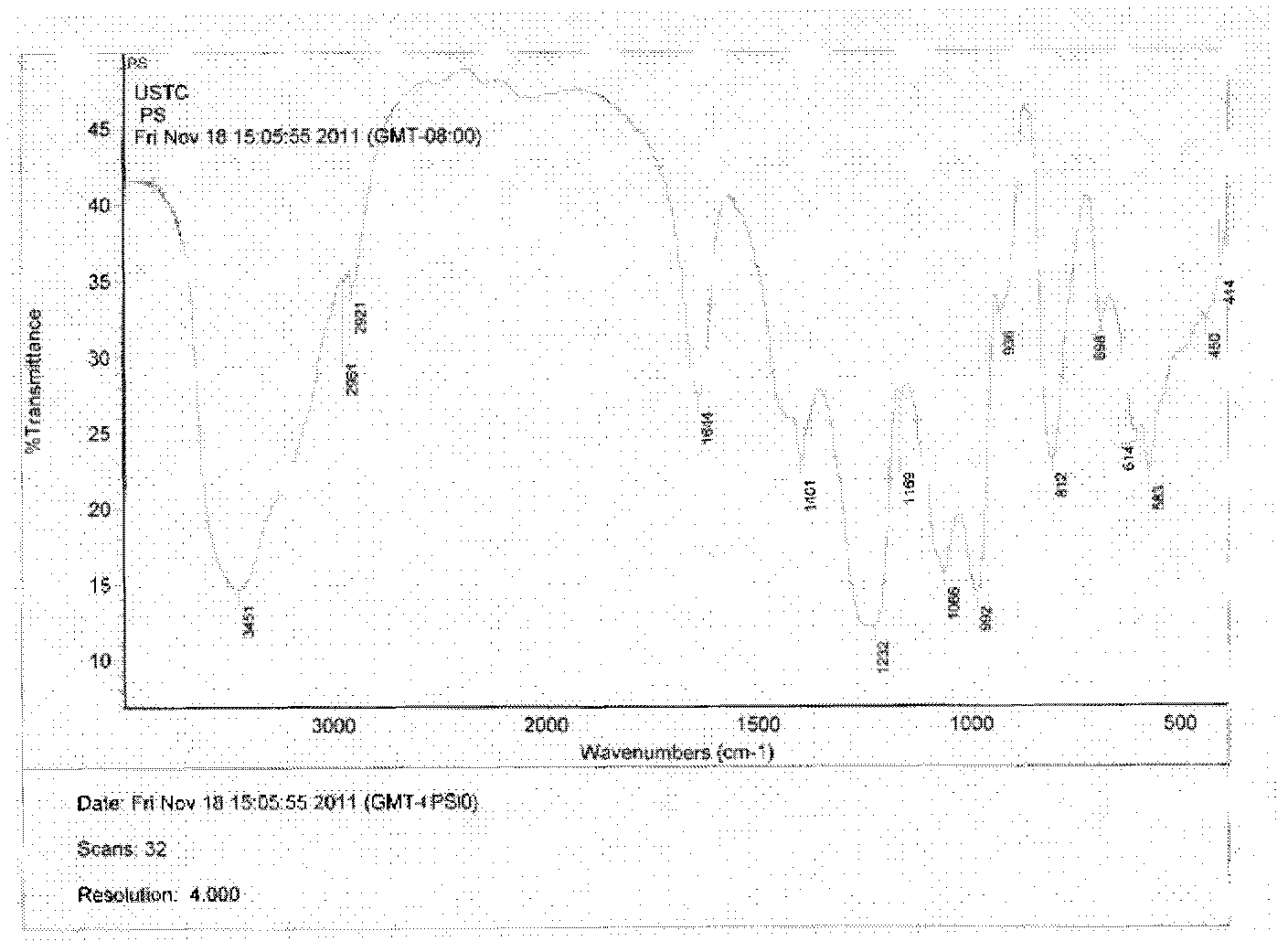

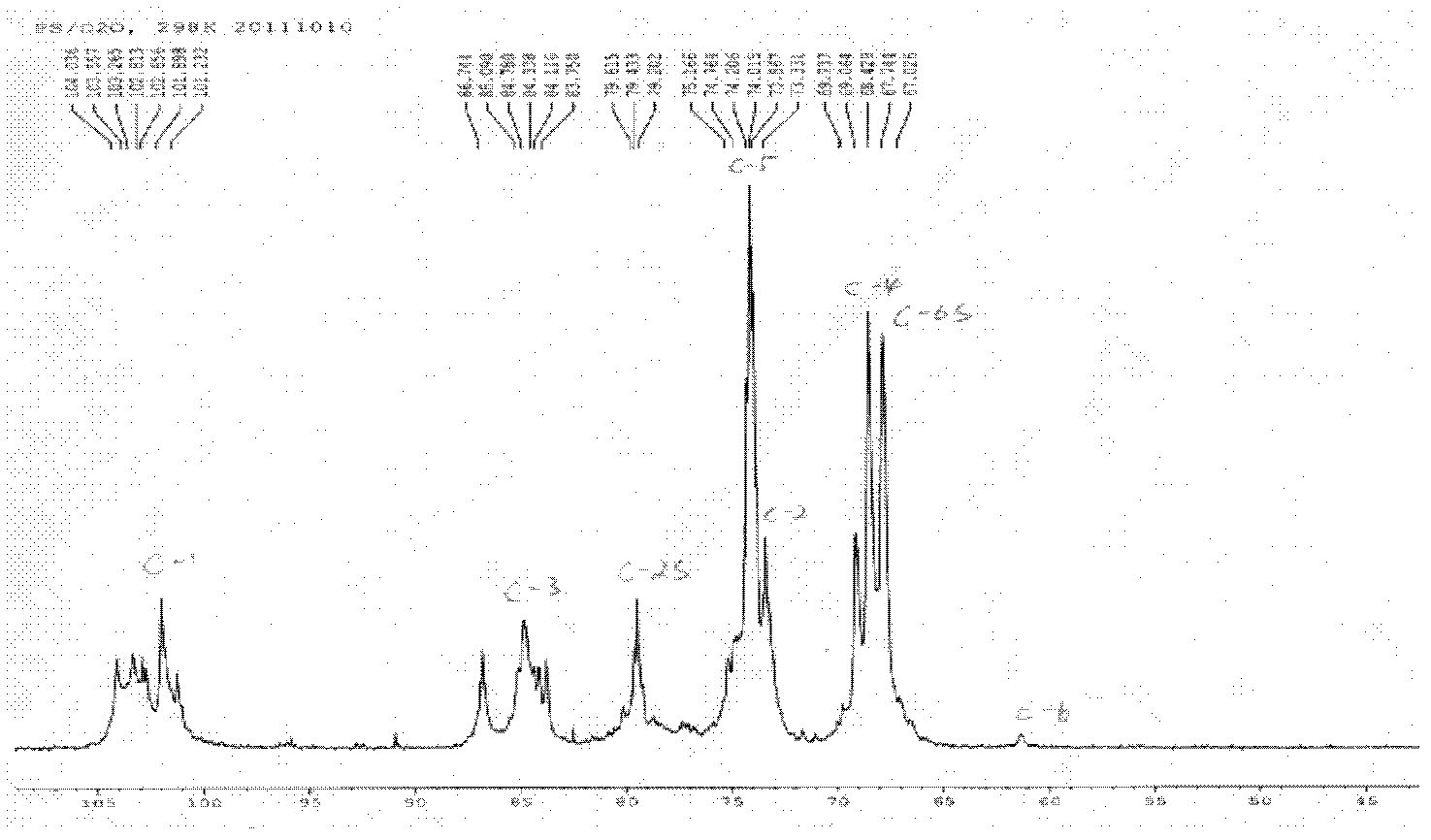

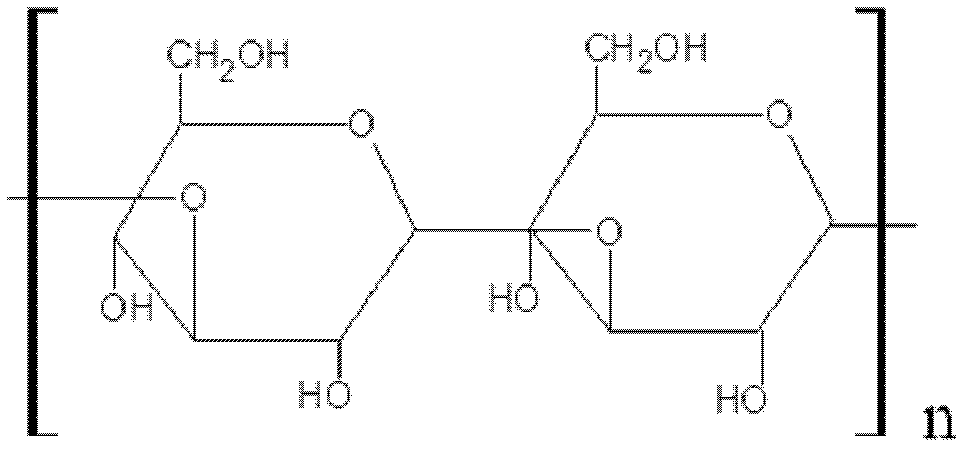

[0031] A preparation method of polysaccharide sulfate, characterized in that:

[0032] Include the following steps:

[0033] (1), poria cocos is peeled, dried, pulverized, and dissolved in 0.5mol / L NaOH whose total volume is 10-15 times its total volume for 3-5 times, and the polysaccharides are extracted at 4-10°C for 5-10h each time, and combined Extract the obtained supernatant, neutralize the supernatant to pH 6-8 with about 10% acetic acid, precipitate overnight at 4-10°C, collect the precipitate by centrifugation at low temperature, wash the precipitate with deionized water for 3-5 times, and then use Wash with water, ethanol, acetone and ether in sequence, and dry at 70-90°C to obtain white pachyrhin, which is grinded into powder for later use;

[0034] (2), add sulfamic acid and organic solvent in the reaction flask of rotary evaporator, preheat to about 80 ℃ of reaction temperature, after sulfamic acid dissolves completely, add the dry pachyrhizu powder obtained in s...

Embodiment 2

[0042] 1. Extraction and purification of Poria cocos polysaccharide

[0043] Weigh 100g Poria cocos powder, dissolve in 0.5mol / L NaOH with a total volume of 10 times in 3 times, extract polysaccharides at 4°C for 8 hours each time, combine the leaching supernatants of 3 times, and neutralize with 10% acetic acid to pH6. 5. Precipitate overnight in refrigerator at 4°C. Centrifuge at low temperature to collect the precipitate, wash the precipitate three times with deionized water, wash with absolute ethanol, acetone, and ether in sequence, and dry at 70°C to obtain white polysaccharide, which is ground into powder for use. The polysaccharide content detected by the phenol-sulfuric acid method is 99.2%, and the viscosity-average molecular weight measured by the viscosity method is 2.15×10 5 Da.

[0044] 2. Preparation of Pachyman sulfate (PS)

[0045] (1) Add 200ml of dimethylformamide (DMF) into a 1000ml pear-shaped bottle, heat it in a water bath to 80°C, add 90g of sulfamic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com