Low-alkali liquid accelerator containing microbial polysaccharide and preparation method thereof

A technology of microbial polysaccharides and accelerators, applied in the field of concrete admixtures, can solve the problems of mechanical properties, large loss of durability, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

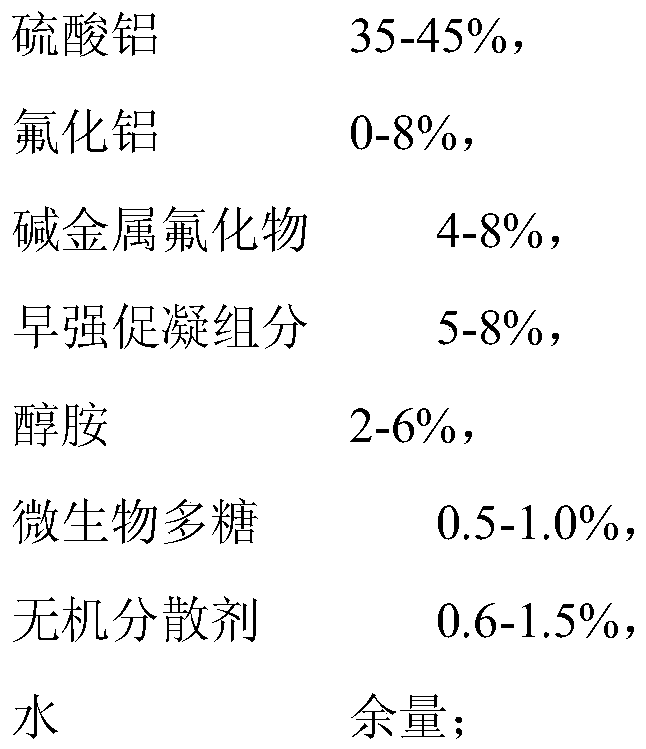

Method used

Image

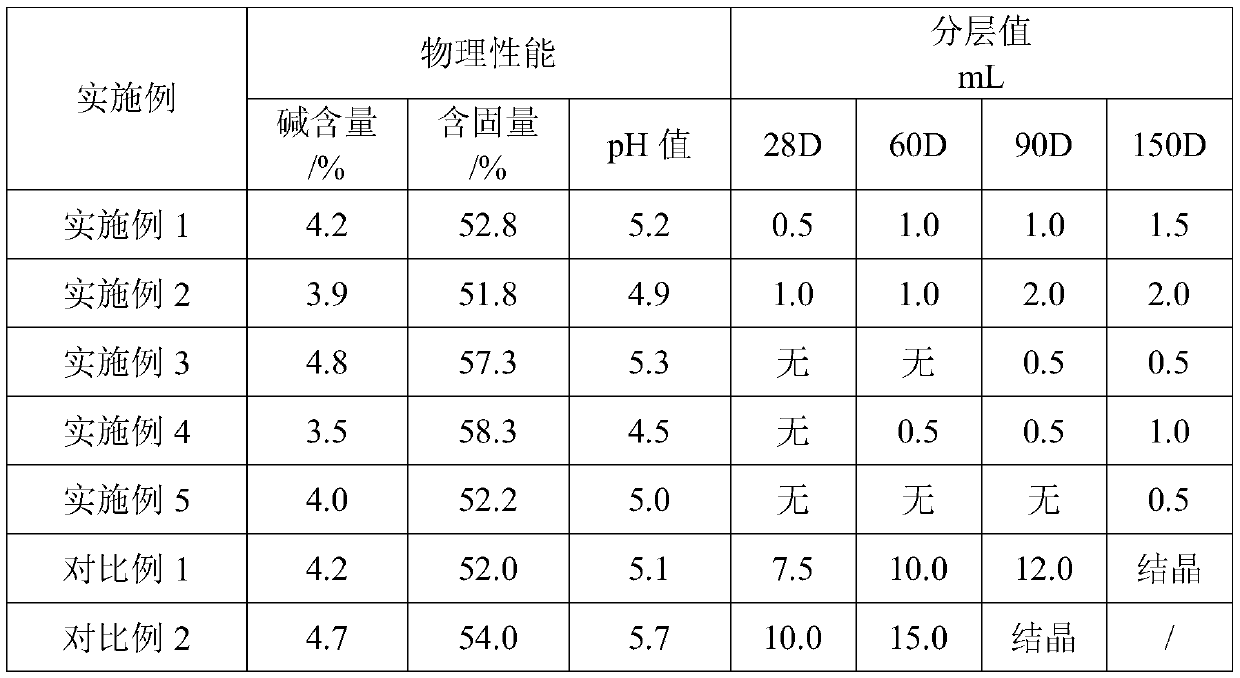

Examples

Embodiment 1

[0032] A preparation method of a low-alkali liquid quick-setting agent containing microbial polysaccharides, comprising the following steps:

[0033] (1) Mix 186g of water and 5g of hydrated magnesium silicate evenly, and disperse at a high speed of 3900r / min for 50min to obtain a pre-dispersed sol; heat the pre-dispersed sol to 50°C, and mix it while stirring at a speed of 1000r / min Slowly add 2g gellan gum and 2g Wenlun gum, keep warm and dissolve for 40 minutes to obtain a dispersion stabilizer containing microbial polysaccharides;

[0034] (2) Add 200g of aluminum sulfate, 20g of aluminum fluoride, 40g of calcium fluoride, and 15g of diethanolamine into the dispersion stabilizer obtained in step (1) while stirring in turn, heat up to 75°C and keep it warm for 2.5 hours; cool down to 60°C Finally, add 30g of sodium fluoride, heat the reaction for 35 minutes, and then cool to room temperature to obtain the low-alkali liquid quick-setting agent containing microbial polysaccha...

Embodiment 2

[0036] A preparation method of a low-alkali liquid quick-setting agent containing microbial polysaccharides, comprising the following steps:

[0037](1) Mix 191g of water and 4g of hydrated magnesium silicate evenly, and disperse at a high speed of 3600r / min for 35min to obtain a pre-dispersed sol; heat the pre-dispersed sol to 60°C, and mix the Slowly add 2.5g xanthan gum and 2.5g gellan gum, keep warm and dissolve for 45 minutes to obtain a dispersion stabilizer containing microbial polysaccharides;

[0038] (2) 190g of aluminum sulfate, 30g of aluminum fluoride, 30g of magnesium carbonate, and 25g of mixed alcohol amine (mixed evenly with diethanolamine and triethanolamine in a mass ratio of 1:1), and then add the dispersion stabilizer obtained in (1) while stirring , heat up to 80°C and keep warm for 3.0 hours; after cooling down to 56°C, add 25g of potassium fluoride, keep warm for 60min and then cool to room temperature to obtain a low-alkali liquid quick-setting agent c...

Embodiment 3

[0040] A preparation method of a low-alkali liquid quick-setting agent containing microbial polysaccharides, comprising the following steps:

[0041] (1) Mix 163.5g of water and 4g of magnesium aluminum silicate evenly, and disperse at a high speed of 4500r / min for 60min to obtain a pre-dispersed sol; heat the pre-dispersed sol to 45°C, and stir at a speed of 1000r / min Slowly add 2.5g Wenlun glue, keep warm and dissolve for 50 minutes to obtain a dispersion stabilizer containing microbial polysaccharides;

[0042] (2) 225g of aluminum sulfate, 20g of aluminum fluoride, 25g of magnesium carbonate, and 30g of triisopropanolamine were added to the dispersion stabilizer obtained in (1) while stirring in turn, and the temperature was raised to 85° C. and kept for 3.5 hours; the temperature was lowered to 60 After ℃, add 25g of potassium fluoride and 25g of sodium fluoride, keep it warm for 55 minutes, then cool to room temperature to obtain the low-alkali liquid quick-setting agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com