Movable offshore self-mounting dry type work environment construction process

A technology of working environment and construction technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of high construction difficulty and high construction difficulty for operators, and achieve the optimal relationship and method, safe and effective construction, and reduce difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

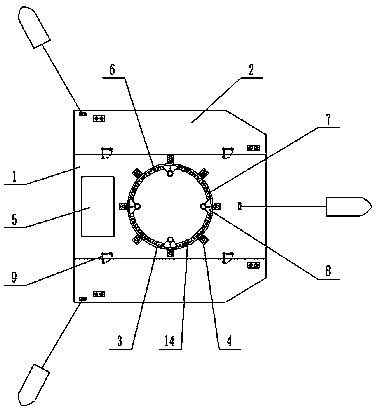

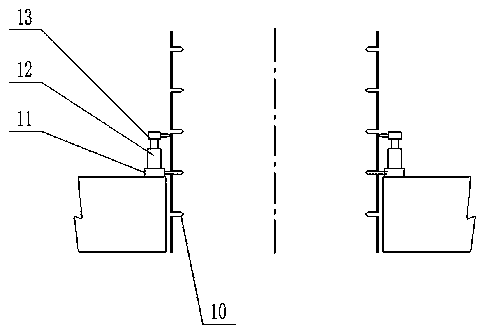

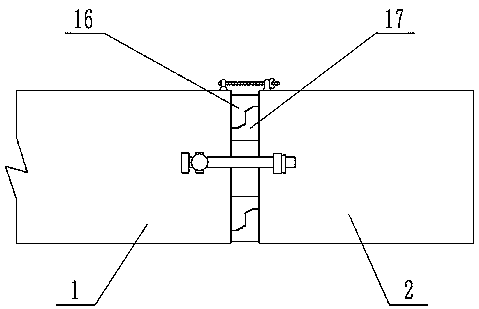

[0043] Specific embodiments are designed as follows.

[0044] (1) Parameter design

[0045] In order to ensure the normal progress of the construction process and the proper implementation of each link, the simulation data is calculated to ensure its feasibility. Here, the parameters of the cylinder are designed as follows: the outer diameter of the operation cylinder is 15m, the height is 36m, and the weight is about 700t; the platform box (main The total weight of tank 1 and auxiliary floating tank 2) is about 950t; the platform tank can carry a total weight of about 4000t of water.

[0046] (2) Penetration capability analysis

[0047] Through the analysis of sediment resistance and calculation, the penetration resistance is 2650t, and the maximum reserve penetration force is about 6000t, which can ensure smooth self-insertion penetration and reach the predetermined depth below the mud surface (the bottom of the tube is located 10m below the mud surface).

[0048] (3) Anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com