Integrated inert-gas frequency standard device for laser frequency locking

An inert gas, reference device technology, applied in lasers, laser parts, electrical components, etc., can solve the problems of fragility, difficult adjustment, complex structure, etc., and achieve the effect of maintaining vacuum, compact overall structure, and easy to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

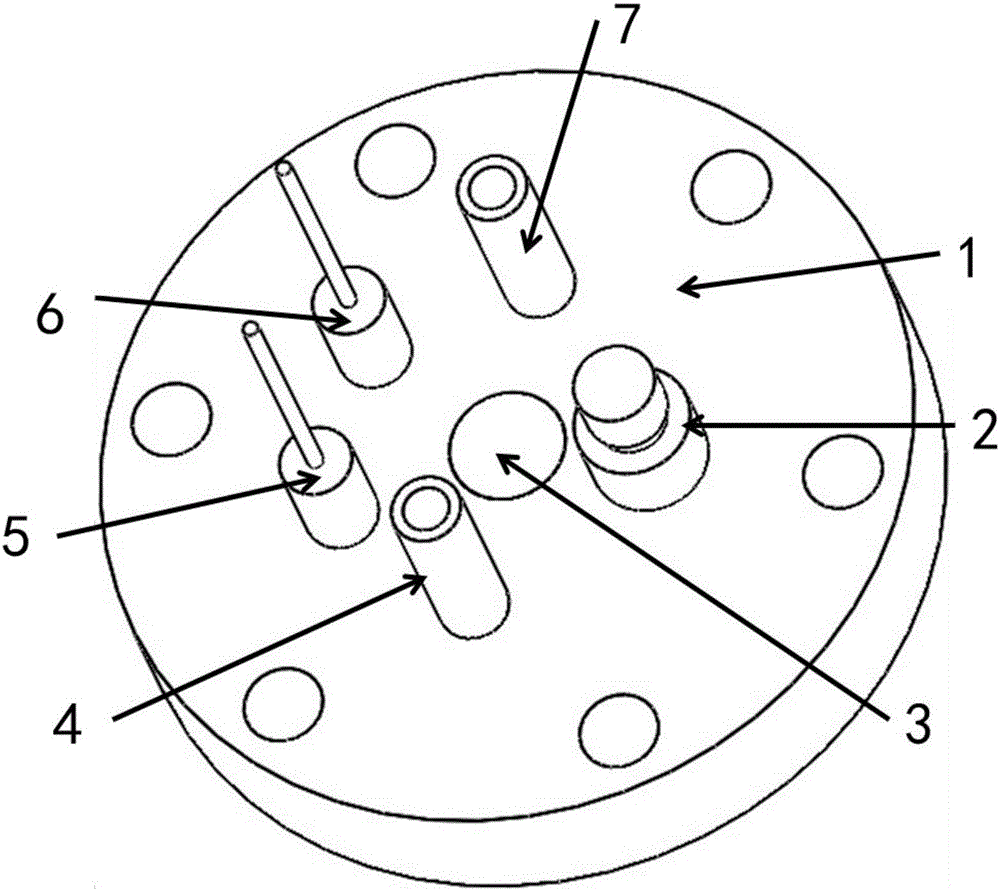

[0019] figure 1 It is a schematic diagram of the vacuum flange structure of the inert gas frequency reference device. Vacuum flange 1 adopts detachable all-metal sealing method and figure 2 The vacuum chamber shown makes the vacuum connection. The radio frequency input electrode 2, the vacuum pumping and gas filling pipes 4 and 7, the vacuum electrodes 5 and 6 are welded on the flange 1 by argon arc welding, and the vacuum inner surface is welded to ensure the vacuum performance; the laser observation window 3 is brazed On the flange, it can be coated to improve the laser transmittance according to the need. Only the structural schematic diagram of the flange is drawn in the figure.

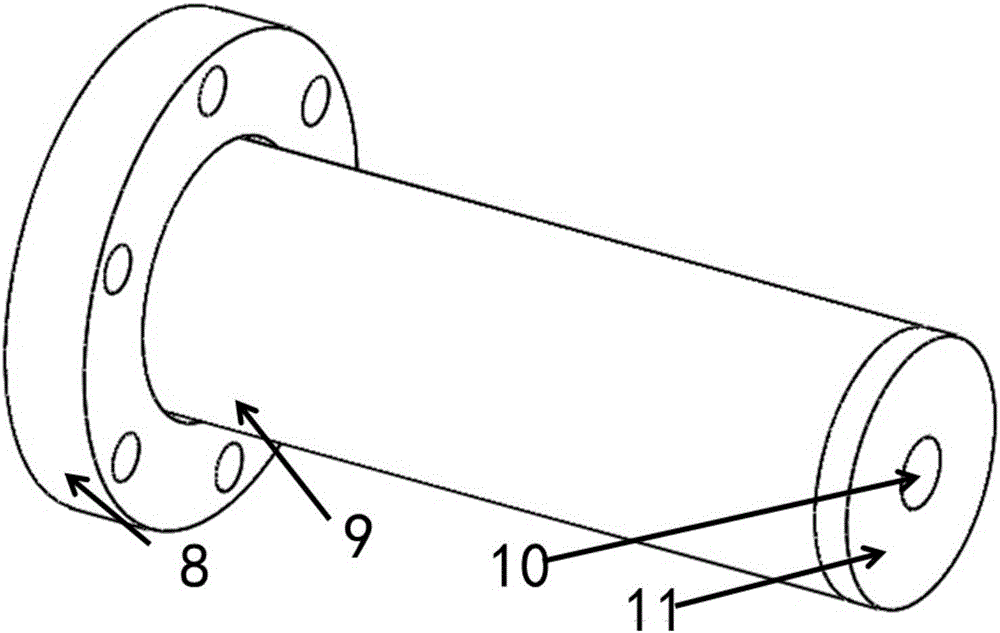

[0020] Such as figure 2 As shown, the vacuum chamber of the inert gas frequency reference device is composed of an interface flange 8, a vacuum chamber pipe 9, and a vacuum chamber bottom plate 11 to form an overall structure by means of argon arc welding. The laser window 10 and figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com