A kind of energy-saving and environment-friendly material, its preparation method and its application in building system

An energy-saving, environmentally friendly, bonding material technology, applied in the field of building materials, can solve the problems of poor heat resistance, cumbersome construction steps of thermal insulation mortar, performance degradation, etc., and achieve the effect of enhancing the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

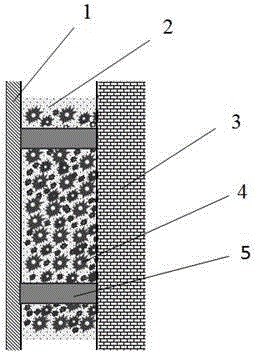

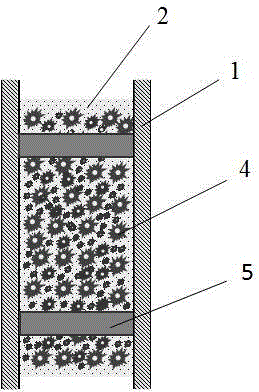

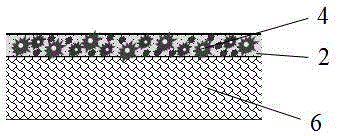

[0030] An energy-saving and environment-friendly material. The energy-saving and environment-friendly material comprises the following raw materials in parts by weight: 80% of a glass hollow body, 15% of a bonding material, and 5% of water. The above materials are stirred and mixed evenly.

[0031] The glass hollow body 4 is made of waste glass, and is selected as a sphere, and has three different ranges of particle diameters. The large particle diameter glass hollow body has a particle diameter of 25mm, the wall thickness is 10mm, and the medium particle diameter glass hollow body has a particle diameter of 7mm. , the wall thickness is 3mm, the particle size of the small particle size glass hollow body is 1.5mm, and the wall thickness is 0.3mm. The glass hollow body 4 has 2 parts by weight of a large-diameter glass hollow body, 3 parts by weight of a medium-sized glass hollow body, and 8 parts by weight of a small-diameter glass hollow body.

[0032] The cavity of the glass h...

Embodiment 2

[0035] An energy-saving and environment-friendly material. The energy-saving and environment-friendly material comprises the following raw materials in parts by weight: 90% of a glass hollow body, 25% of a bonding material, and 8% of water. The above materials are stirred and mixed evenly.

[0036]The glass hollow body 4 is made of waste glass, and is selected as a sphere. There are three different ranges of particle sizes. The large particle size glass hollow body has a particle size of 35 mm, the wall thickness is 15 mm, and the medium particle size glass hollow body has a particle size of 10 mm. , the wall thickness is 5mm, the particle size of the small particle size glass hollow body is 3mm, and the wall thickness is 0.5mm. The glass hollow body 4 has 2 parts by weight of a large-sized glass hollow body, 4 parts by weight of a medium-sized glass hollow body, and 10 parts by weight of a small-sized glass hollow body.

[0037] The inner wall of the hollow glass body 4 is fi...

Embodiment 3

[0040] An energy-saving and environment-friendly material. The energy-saving and environment-friendly material comprises the following raw materials in parts by weight: 65% of a glass hollow body, 5% of a bonding material, and 3% of water. The above materials are stirred and mixed evenly.

[0041] The glass hollow body 4 is made of waste glass, and is selected as a sphere. There are three different ranges of particle diameters. The large particle diameter glass hollow body has a particle diameter of 15mm, the wall thickness is 5mm, and the medium particle diameter glass hollow body has a particle diameter of 5mm. , the wall thickness is 1mm, the particle size of the small particle size glass hollow body is 0.5mm, and the wall thickness is 0.1mm. The glass hollow body 4 has 1 part by weight of a large-sized glass hollow body, 2 parts by weight of a medium-sized glass hollow body, and 6 parts by weight of a small-sized glass hollow body.

[0042] The glass hollow body 4 is a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com