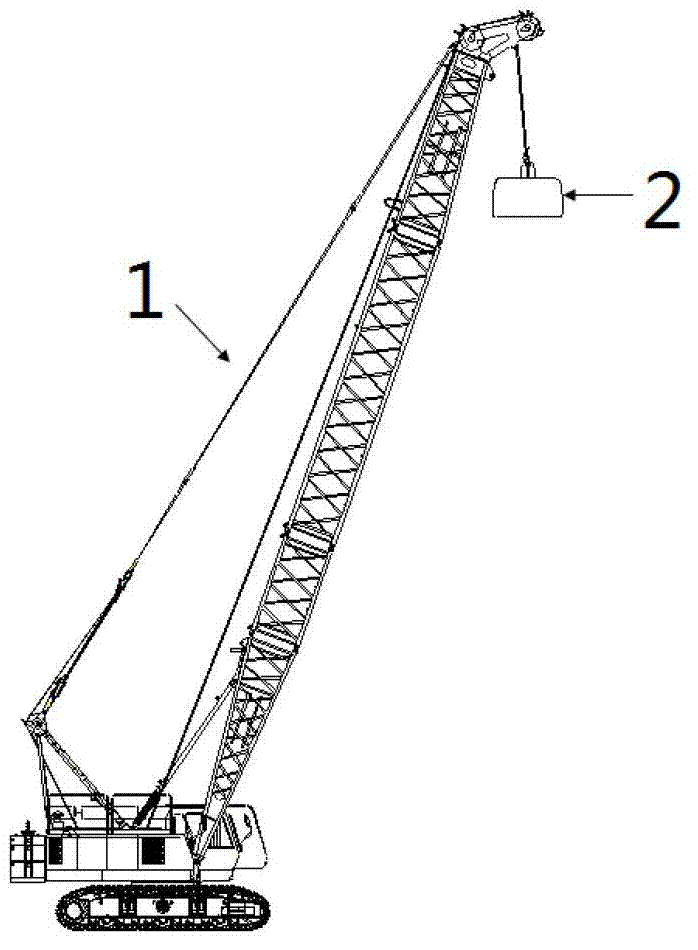

Ramming hammer

A rammer-integrated technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of high cost, broken rammer, different impact force, etc. low height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

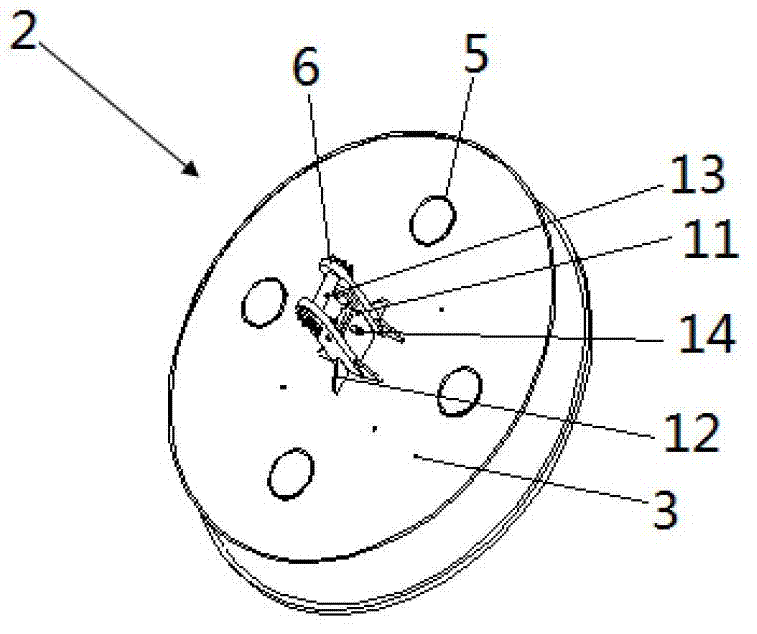

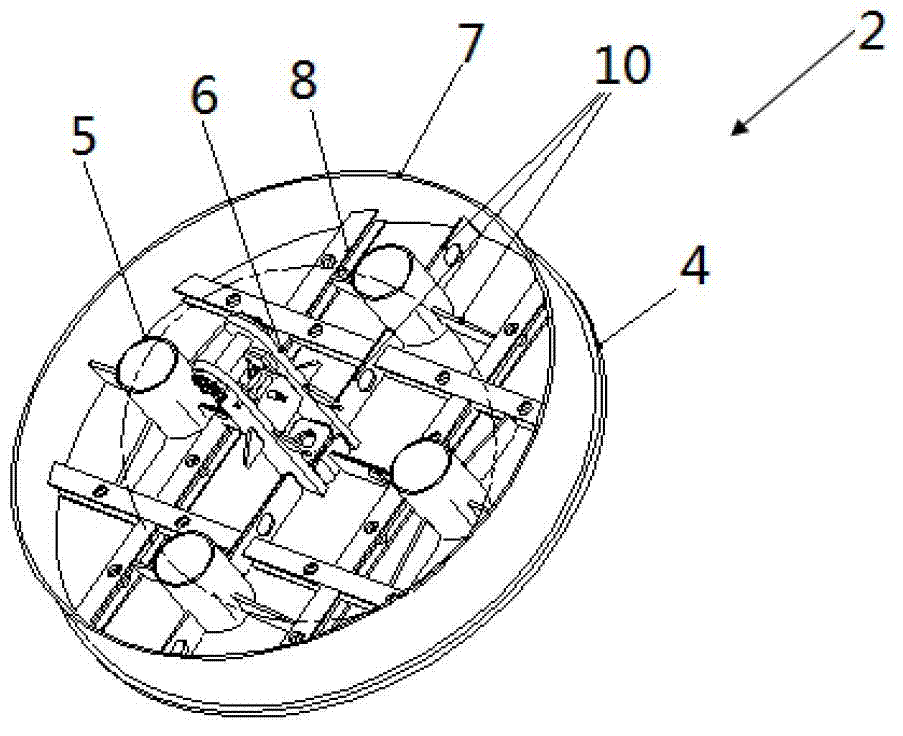

[0027] figure 2 with image 3 One embodiment of the rammer provided by the present invention is shown, as figure 2 , image 3 As shown, the rammer includes a base and a cover plate 3, the base and the cover plate 3 form a closed space, a steel frame and a lifting rib 6 welded on the bottom plate 4 of the base, and cast in the gap of the closed space of concrete (concrete not shown in the diagram). Wherein, the lifting ribs 6 all run through the cover plate 3, and the lifting ribs 6 and the cover plate 3 are welded into one body, and the lifting ribs 6 are provided with lifting parts.

[0028] In this embodiment, the base can include a bottom plate 4 and a side wall 7, and the bottom plate 4 and the side wall 7 are welded together. At this time, the closed space is a hollow cylindrical cavity. Obviously, the close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com