Manganese-oxygen compound three-dimensional porous material for removing formaldehyde and preparation method thereof

A manganese oxide compound and three-dimensional porous technology, which is applied in the field of formaldehyde removal materials and its preparation, can solve the problems of restricting the promotion and application of formaldehyde removal, immature titanium dioxide technology, and slow metabolism of plants at night, achieving high formaldehyde removal activity and forming The effect of low difficulty and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

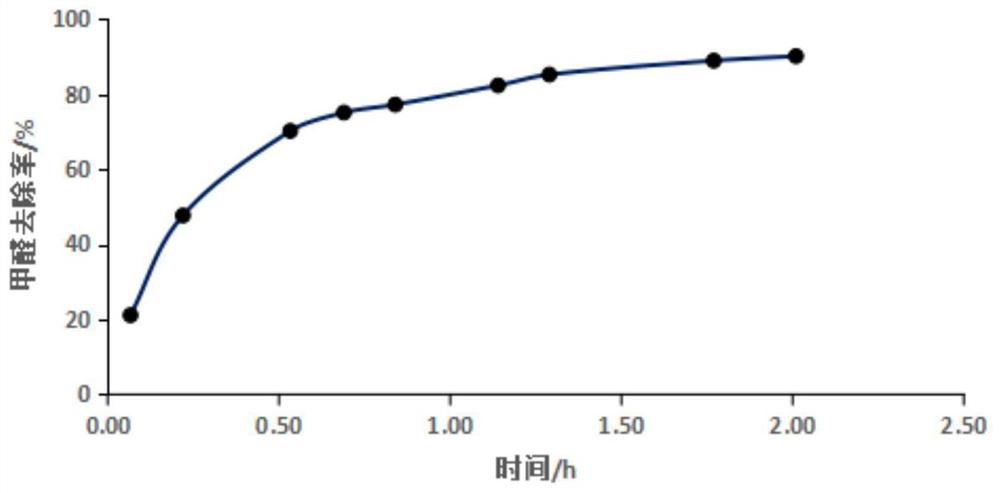

Examples

Embodiment 1

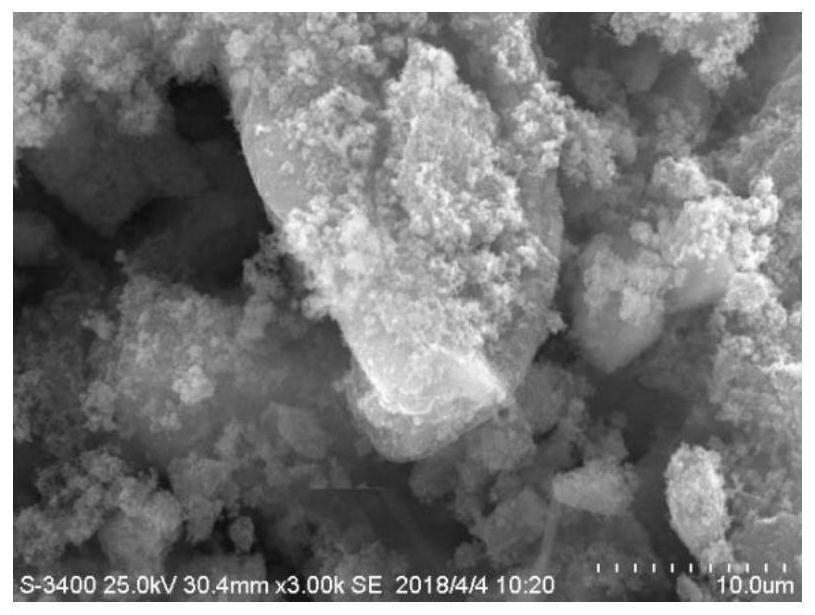

[0029] (1) Dissolve 2 parts of NaOH into 100 parts of pure water, stir until completely dissolved, add 3 parts of KMnO 4 Continue stirring until completely dissolved to obtain a mixed solution A; 4 parts of MnSO 4 Dissolve in 100 parts of pure water, heat to 60°C after complete dissolution, add solution A dropwise to MnSO under stirring condition 4 The solution was stirred and maintained at 60°C for 3h to obtain mixture B.

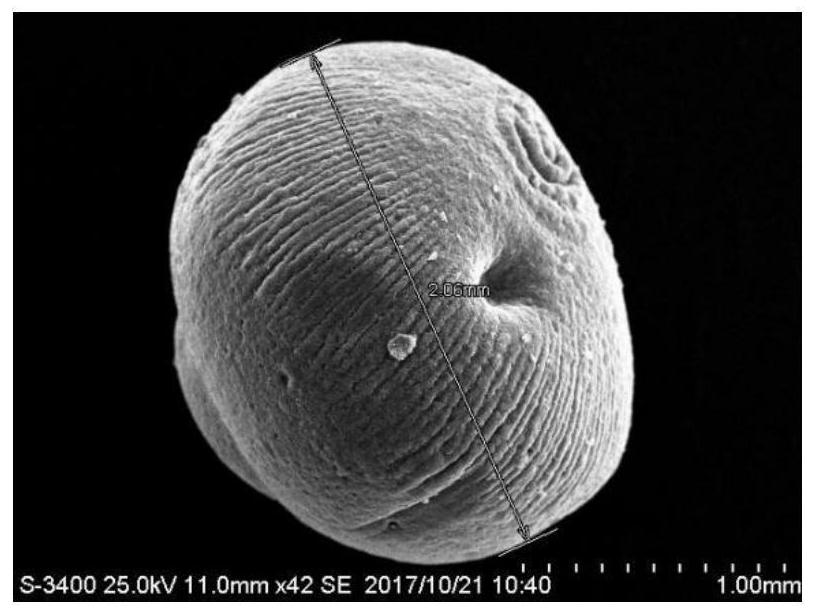

[0030] (2) Take 100 parts of mixture B and age at room temperature for 24 hours, add 10 parts of large-grain bamboo fibers into mixture B, wherein the length of large-grain bamboo fibers is 0.1-0.3 mm; stir for 20 minutes to obtain mixture C; then add 0.5 parts Sodium alginate was added to 20 parts of pure water to dissolve completely, added to mixture C, and stirred completely to obtain mixture D. Mixture D was slowly added dropwise to 10% CaCl 2 The solution was aged for 10 minutes and then taken out to obtain gel beads E.

[0031] (3) Gel beads E we...

Embodiment 2

[0036] (1) Dissolve 2.2 parts of NaOH into 100 parts of pure water, stir until completely dissolved, add 3.8 parts of NaMnO 4 Continue stirring until completely dissolved to obtain mixed solution A; 5.2 parts of MnSO 4 Dissolve in 100 parts of pure water, completely dissolve at room temperature and heat to 25°C, add solution A dropwise to MnSO under stirring condition 4 The solution was stirred and maintained at 25°C for 2h to obtain mixture B.

[0037] (2) Take 100 parts of mixture B and age at room temperature for 12 hours, add 10 parts of large-grain bamboo fibers into mixture B, wherein the length of large-grain bamboo fibers is 0.5-1.0 mm; stir for 20 minutes to obtain mixture C; then add 0.8 parts Sodium alginate was added to 20 parts of pure water to dissolve completely, added to mixture C, and stirred completely to obtain mixture D. Mixture D was slowly added dropwise to 10% CaCl2 solution, aged for 30 minutes and then taken out to obtain gel beads E.

[0038] (3) G...

Embodiment 3

[0042] (1) Dissolve 2.8 parts of KOH into 150 parts of pure water, stir until completely dissolved, add 3.3 parts of NaMnO 4 Continue stirring until completely dissolved to obtain mixed solution A; 4.5 parts of MnCl 2 Dissolve in 150 parts of pure water, heat to 50°C after complete dissolution, add solution A dropwise to MnCl under stirring condition 2 The solution was stirred and maintained at 50°C for 0.5h to obtain mixture B.

[0043] (2) Take 100 parts of mixture B and age at room temperature for 20 hours, add 15 parts of large-grain bamboo fibers into mixture B, wherein the length of large-grain bamboo fibers is 0.3-0.5 mm, stir for 40 minutes, and obtain mixture C; Sodium alginate was added to 20 parts of pure water to dissolve completely, added to mixture C, and stirred completely to obtain mixture D. Mixture D was slowly added dropwise to 20% CaCl 2 The solution was aged for 60 minutes and then taken out to obtain gel beads E. The specific raw materials and effect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com