Production method of ultra-thin steel belt plated with precious metal

A technology of precious metal plating and production method, which is applied in the direction of metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of easy oxidation, easy corrosion of sulfide, high production cost, etc., and achieve stability and Improved compactness, precise control of coating thickness, and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in detail below:

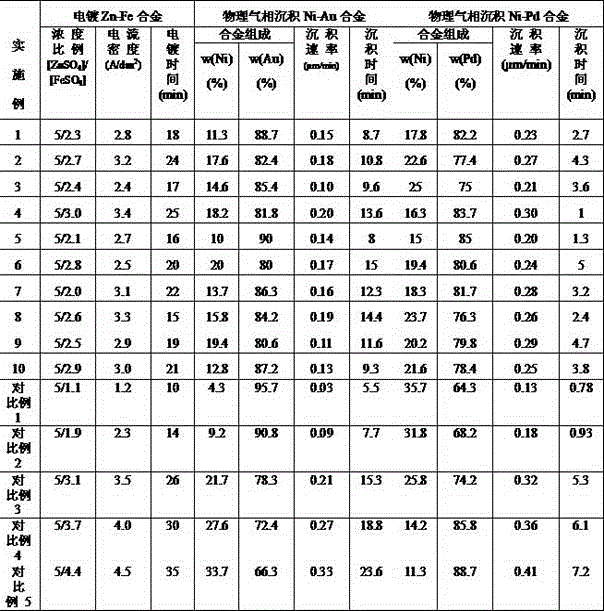

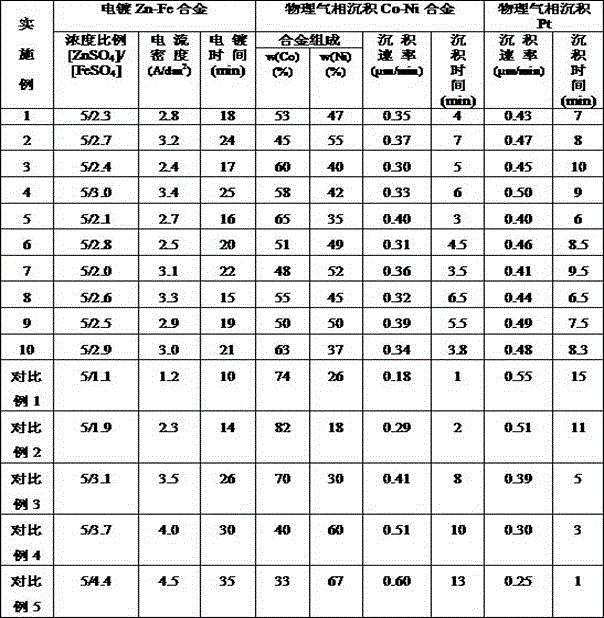

[0046] Table 1 is the list of cold rolling process parameters of each embodiment of the present invention and comparative examples;

[0047] Table 2 is the tape making process parameter list of each embodiment of the present invention and comparative example;

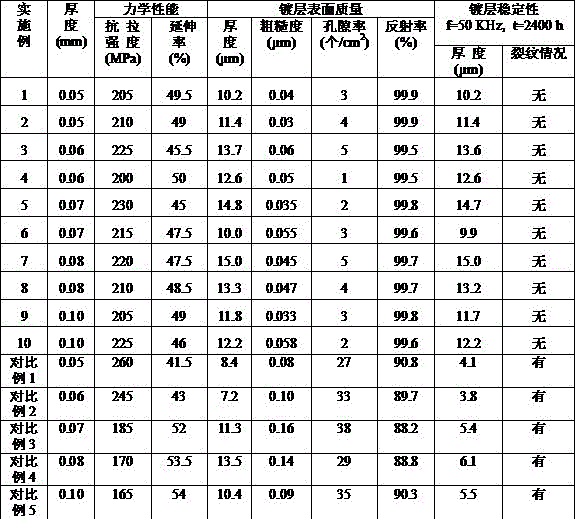

[0048] Table 3 is a product performance list of each embodiment of the present invention and comparative examples.

[0049] Each embodiment of the present invention is all produced according to the following steps:

[0050] 1) Using ordinary DC01 cold-rolled steel plate as raw material, carry out 3~4 passes of repeated cold rolling, and control the total reduction rate to 55~65%.

[0051] Then conventional degreasing;

[0052] 2) Annealing is carried out under the protective atmosphere of full hydrogen, the annealing temperature is controlled at 580-620 °C, and the holding time is 45-55 min;

[0053] 3) Tape making:

[0054] A. Unwinding, slitting and deb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com