Preparation method and application of high-temperature membrane fuel cell gas diffusion electrode

A gas diffusion electrode, fuel cell technology, applied in fuel cells, battery electrodes, electrical components, etc., can solve the problems of membrane electrodes prone to deformation, poor performance, internal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of gas diffusion electrodes

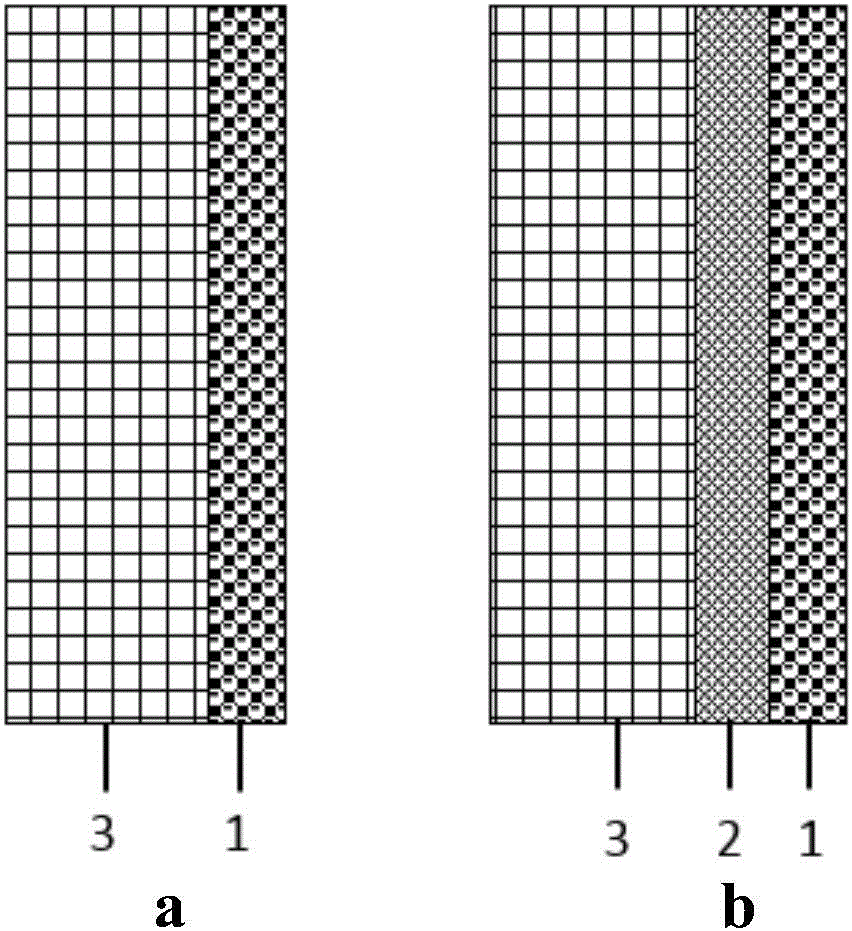

[0045] Prepared according to the steps described in the summary of the present invention figure 1 A gas diffusion electrode free of microporous layers is shown. The size of the prepared gas diffusion electrode is 2.3cm×2.3cm. The gas diffusion back layer is Toray TGP-H-90 carbon paper, the hydrophobic agent is polytetrafluoroethylene (PTFE), and the mass percentage of PTFE in the carbon paper after treatment is 25wt.%. The catalyst used is JohnsonMatthey20wt.%Pt / C catalyst, and the Pt loading of the catalytic layer is 0.7mg / cm 2 ; The catalytic layer binder is also PTFE, and the percentage in the catalytic layer is 25wt.%.

[0046] (2) Preparation of Membrane Electrode Assembly

[0047] The electrolyte membrane is a phosphoric acid-doped ABPBI membrane with a size of 4cm×4cm and a phosphoric acid doping amount of 370wt.%. In the membrane electrode hot-pressing mold, place two prepared identical gas diffusion electrodes ...

Embodiment 2

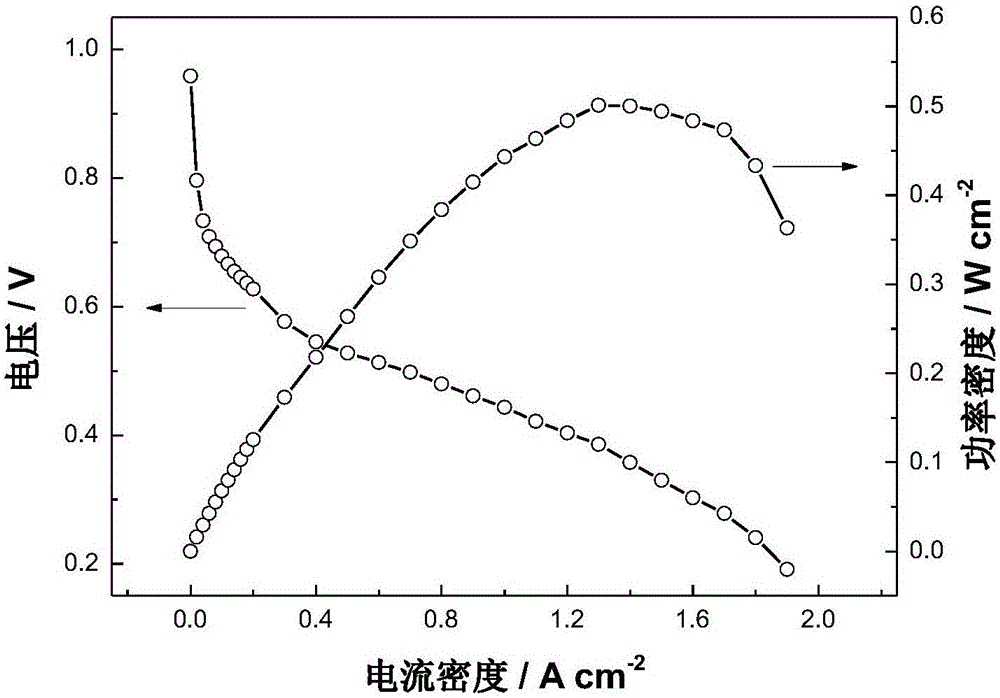

[0051] The gas diffusion back layer is Toray UT70-30 carbon cloth, and the preparation and testing steps of other materials are the same as in Example 1. Test results such as image 3 shown. from image 3 It can be seen that the current density of the battery can reach 0.24A / cm under the working voltage of 0.6V 2 , the maximum power density reaches 0.50W / cm 2 .

Embodiment 3

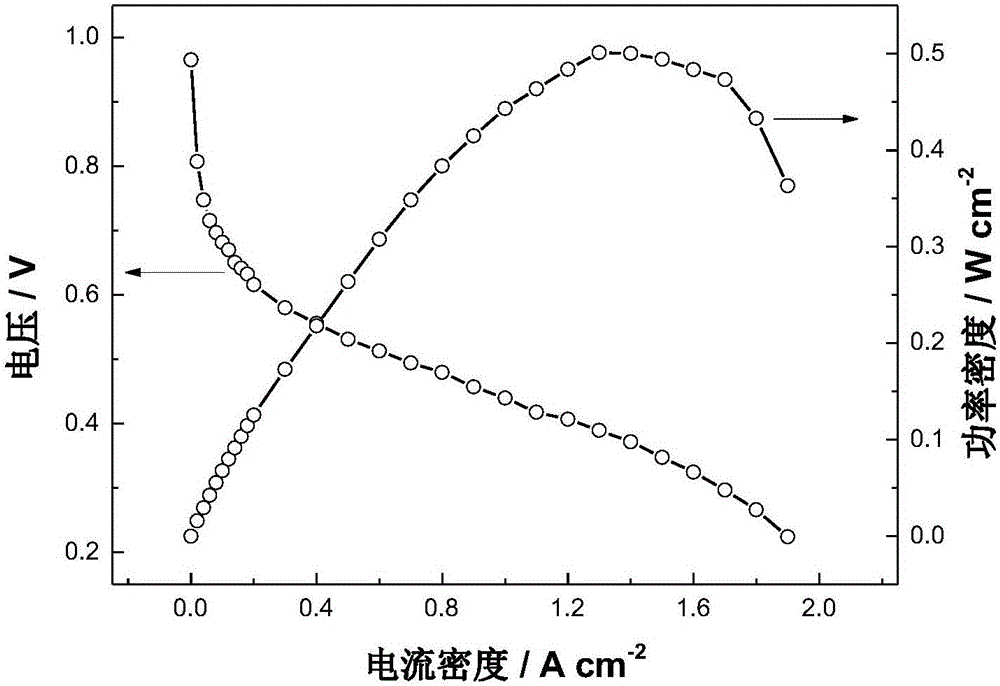

[0053] The catalyst is Johnson Matthey 40wt.% Pt / C catalyst, and the preparation and testing steps of other materials are the same as in Example 1. Test results such as Figure 4 shown. from Figure 4 It can be seen that the current density of the battery can reach 0.27A / cm under the working voltage of 0.6V 2 , the maximum power density reaches 0.54W / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com