Method for macroscopically preparing MOFs (metal-organic framework)@natural polymer novel composite material

A technology of natural polymers and composite materials, which is applied in the field of macro-scale preparation of MOFs@natural polymer new composite materials, can solve the problems such as the influence of the performance of new MOFs@polymer composite materials that have not been reported, and achieves wide source, simple process, Expand the effect of practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

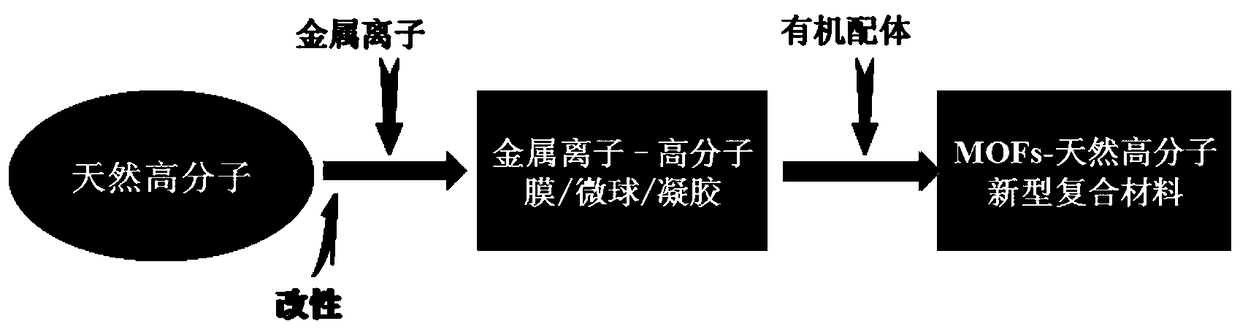

[0024] A method for macro-preparing MOFs@natural polymer novel composite materials, which is prepared from natural polymers, metal salts and carboxylic acid organic ligands, and specifically includes the following steps:

[0025] (1) According to the weight ratio of metal salt: natural macromolecule: carboxylic acid organic ligand: 3:7:1.6, take metal salt, natural macromolecule and carboxylic acid organic ligand for subsequent use; the metal salt copper nitrate, the natural polymer is chitosan, and the carboxylic acid organic ligand is trimesic acid;

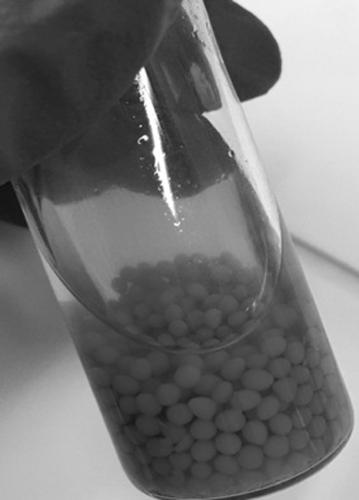

[0026] (2) Modify the natural polymer, the specific modification method is: mix butanol and water according to the volume ratio butanol: water ratio of 7: 1 to obtain a mixed solvent, according to the natural polymer: mixed solvent is 1.5: 100% by weight of the natural polymer dispersed in the mixed solvent, then add magnesium sulfate and mix together, react for 3 h, the modified natural polymer solution can be obtained, the we...

Embodiment 2

[0030] A method for macro-preparing MOFs@natural polymer novel composite materials, which is prepared from natural polymers, metal salts and carboxylic acid organic ligands, and specifically includes the following steps:

[0031] (1) According to the weight ratio of metal salt: natural polymer: carboxylic acid organic ligand: 1:2:0.5, the metal salt, natural polymer and carboxylic acid organic ligand are used for subsequent use; the metal salt is zinc nitrate, the natural polymer is chitin, and the carboxylic acid organic ligand is terephthalic acid;

[0032](2) To modify the natural polymer, the specific modification method is: mix alkaline isopropanol and water according to the volume ratio of alkaline isopropanol: water 6: 0.5 to obtain a mixed solvent, according to the natural polymer : the mixed solvent is 1:100 weight ratio and the natural macromolecule is dispersed in the mixed solvent, then add sodium chloroacetate and mix and stir together, react 2h, can obtain the mo...

Embodiment 3

[0036] A method for macro-preparing MOFs@natural polymer novel composite materials, which is prepared from natural polymers, metal salts and carboxylic acid organic ligands, and specifically includes the following steps:

[0037] (1) According to the weight ratio of metal salt: natural polymer: carboxylic acid organic ligand: 5:12:2.5, take metal salt, natural polymer and carboxylic acid organic ligand for subsequent use; the metal salt is ferric chloride, the natural macromolecule is starch, sodium alginate and sea squirt, and the carboxylic acid organic ligand is pyromellitic acid;

[0038] (2) To modify the natural polymer, the specific modification method is: mix glycerin and water according to the ratio of glycerol: water in the volume ratio of 8:2 to obtain a mixed solvent, according to the weight of natural polymer: mixed solvent is 2:100 Ratio Disperse the natural polymer in the mixed solvent, then add the modifier and mix and stir together, and react for 4 hours to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com