Processing method of fresh-cut potato rice-flour

A fresh-cut potato, processing method technology, applied in the field of food processing, can solve the problems of high amylopectin content, difficult to achieve, high viscosity, etc., and achieve the effect of good color, simple process and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

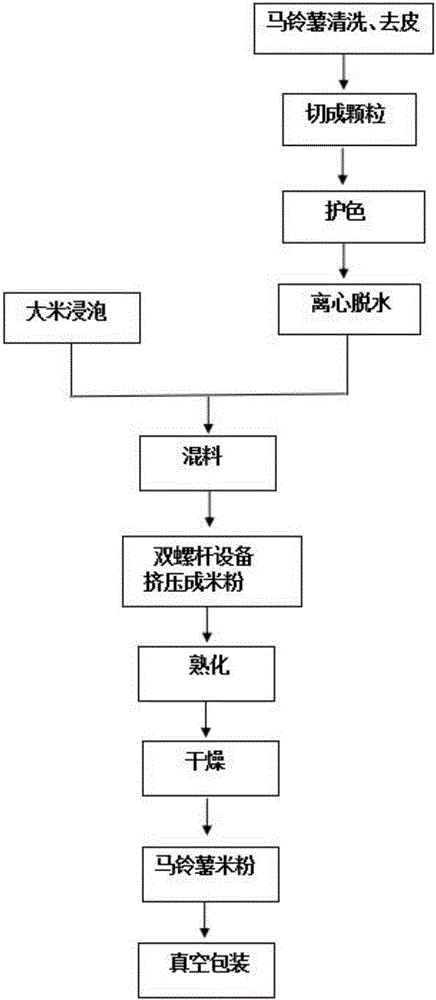

Image

Examples

Embodiment 1

[0032] (1) Soaking rice: Soak the rice for 20 hours, and gently grind the rice grains by hand. If it can be powdered and there is no obvious grain feeling, it means that the soaking has met the requirements; remove the rice, drain the surface moisture, and the moisture content of the rice after soaking is 35%. .

[0033] (2) Preparation of fresh-cut potato granules: fresh potatoes are washed, peeled, and cut into rice grain-sized granules; soaked in color-protecting solution for 20 minutes; Put the mesh bag into the centrifuge dehydrator and centrifuge for 6 minutes until the moisture content of the potatoes reaches 75%. Wherein the color protection solution contains the following substances: 0.4% of sodium chloride, 0.2% of calcium chloride, 0.2% of ascorbic acid and 0.2% of citric acid.

[0034](3) Combination of fresh-cut potato granules and rice: Mix fresh-cut potato granules and 3 times the mass of soaked rice evenly.

[0035] (4) Setting of twin-screw extrusion equipme...

Embodiment 2

[0045] (1) Soaking rice: Soak the rice for 18 hours, and gently grind the rice grains by hand. If it can be powdered and there is no obvious grain feeling, it means that the soaking has met the requirements; remove the rice, drain the surface moisture, and the moisture content of the rice after soaking is 33%. .

[0046] (2) Preparation of fresh-cut potato granules: fresh potatoes are washed, peeled, and cut into rice-sized granules; soaked in color-protecting solution for 25 minutes; Put the mesh bag into a centrifugal dehydrator or dehydrator, and centrifuge for 8 minutes until the moisture content of the potato is 72%. The color-protecting solution contains the following substances: 0.5% sodium chloride, 0.25% calcium chloride, 0.25% ascorbic acid, 0.15% malic acid and 0.1% citric acid.

[0047] (3) Combination of fresh-cut potato granules and rice: mix fresh-cut potato granules with twice the mass of soaked rice evenly.

[0048] (4) Setting of twin-screw extrusion equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com