End-face-sealed friction surface temperature measuring method

A friction surface and end-face sealing technology, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of difficulty in machining near-surface blind holes, poor measurement accuracy and reliability of end-face sealing friction surface temperature, and achieve good stability, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

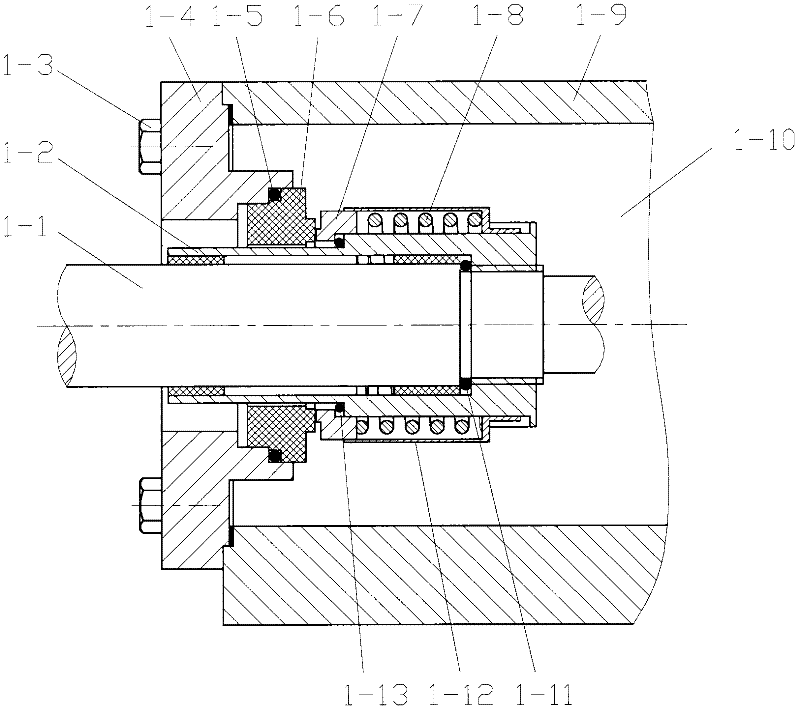

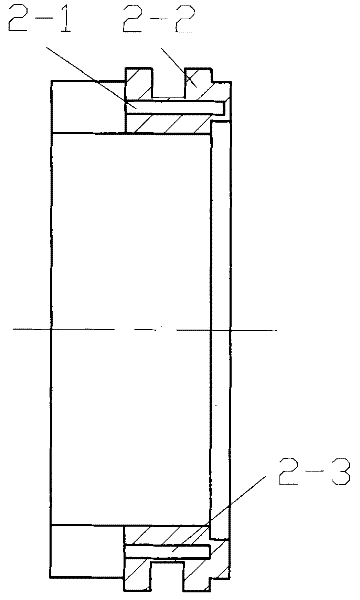

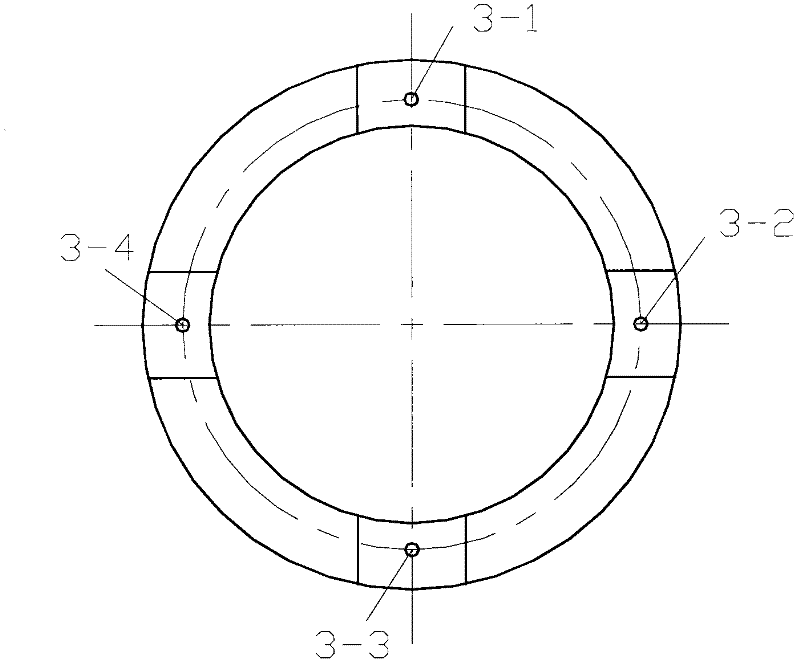

[0027] Embodiment one: Image 6It is the installation state of the end face seal of a single hard static ring in the device. The main shaft 6-1 passes through the end cover 6-5 of the device to be sealed, and extends into the sealing chamber housing 6-13 of the device. The end cover 6-5 of the sealed equipment is connected with the sealing chamber housing 6-13 by bolts 6-4. The static ring 6-8 of the end face seal is supported in the inner hole on the right side of the end cover 6-5 of the sealed equipment, and the connection between the static ring 6-8 and the end cover 6-5 of the sealed equipment is realized by the O-ring 6-7. between the seals. The other end surface of the static ring 6-8 is in contact with the sealing end surface of the moving ring 6-9, and the other end of the moving ring 6-9 is supported by the elastic element 6-10 to obtain a certain end surface specific load; the elastic element 6-10 is composed of The moving ring seat 6-11, which doubles as the fun...

Embodiment 2

[0029] Embodiment two: Figure 7 It is the installation state of the end face seal with bellows rigid stationary ring in the device. The difference from Example 1 is that the structural form of the end face seal has changed. The original static ring 6-8 is changed to a bellows base 7-7, bellows 7-8 and static ring 7-10 assembly, and the original dynamic Ring 6-9, elastic element 6-10 and moving ring seat 6-11 change moving ring 7-11 into. The temperature measurement system at the end face of the static ring is still composed of thermocouple temperature sensors and the static ring; four thermocouple temperature sensors 7-9, 7-16 (there are two not shown in the figure) are evenly distributed circumferentially on the back of the static ring In the blind hole with a diameter of φ1 opened in the axial direction, the distance from the bottom surface of the blind hole to the friction end faces of the moving ring 7-11 and the static ring 7-10 is 1mm, 2mm, 3mm and 4mm respectively, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com