Planar special-shaped non-circular grinding contouring control method

A contour control and special-shaped technology, applied in the direction of grinding automatic control device, grinding machine parts, grinding/polishing equipment, etc. The effect of convenience and algorithm versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

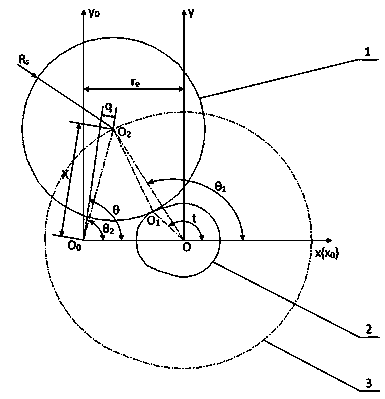

[0020] see figure 1 It is an example of any special-shaped application. The number 1 in the figure is the grinding wheel, the number 2 is the profile of the special shape, and the number 3 is the center of the grinding wheel obtained by the algorithm module. motion track.

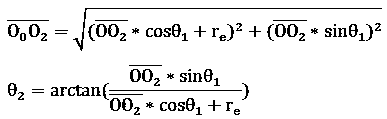

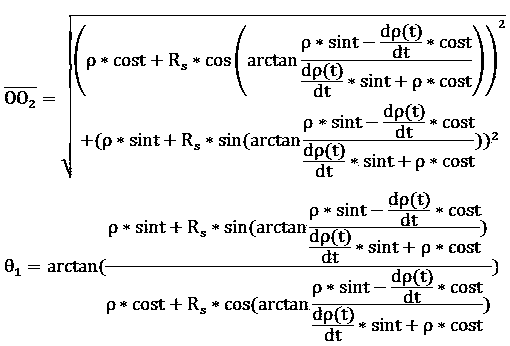

[0021] For the convenience of understanding the technical scheme of the present invention, first make the principle derivation as follows:

[0022]

[0023]

[0024]

[0025] In the formula is the coordinate system xOy (with the center of rotation of the profile is the origin of the coordinates) under any profile point Corresponding grinding wheel center position , After offsetting the coordinate system, in the coordinate system x 0 o 0 the y 0 (C-axis rotation center is the center position of the grinding wheel under the origin of the coordinate system); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com