Multidirectional numerical control hydraulic press for metal plasticity forming

A technology of plastic forming and hydraulic press, which is applied to the driving device of forging presses, etc., can solve the problems of discrete distribution of forming errors, influence on product strength and stiffness, and large cutting processing volume, so as to improve precision, simplify procedures, and high level of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

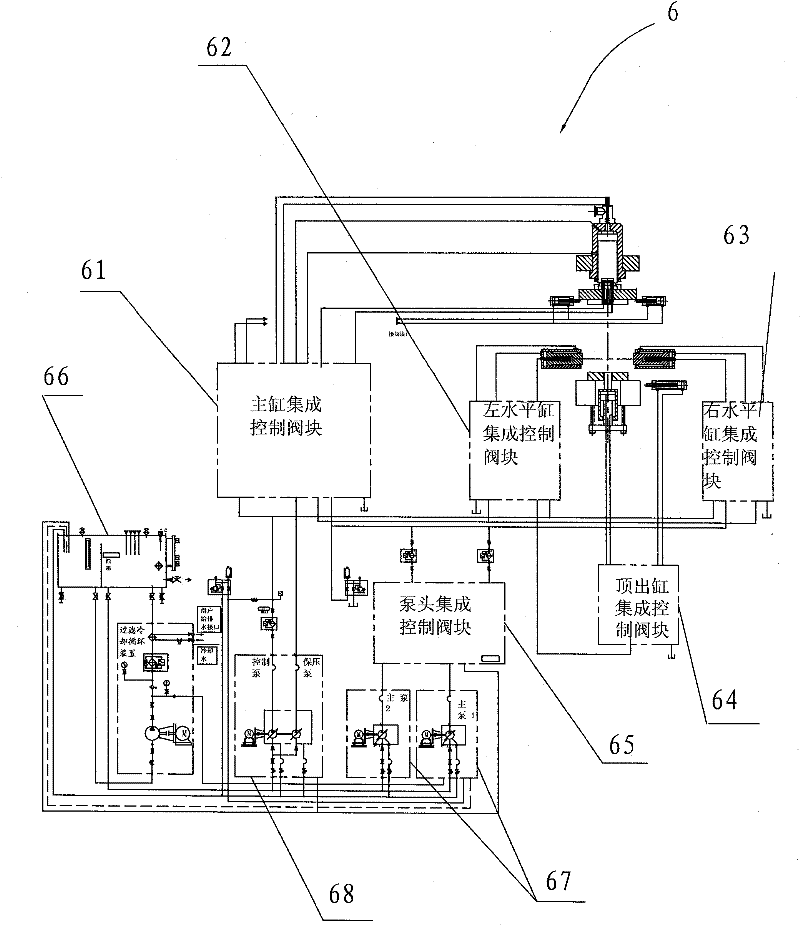

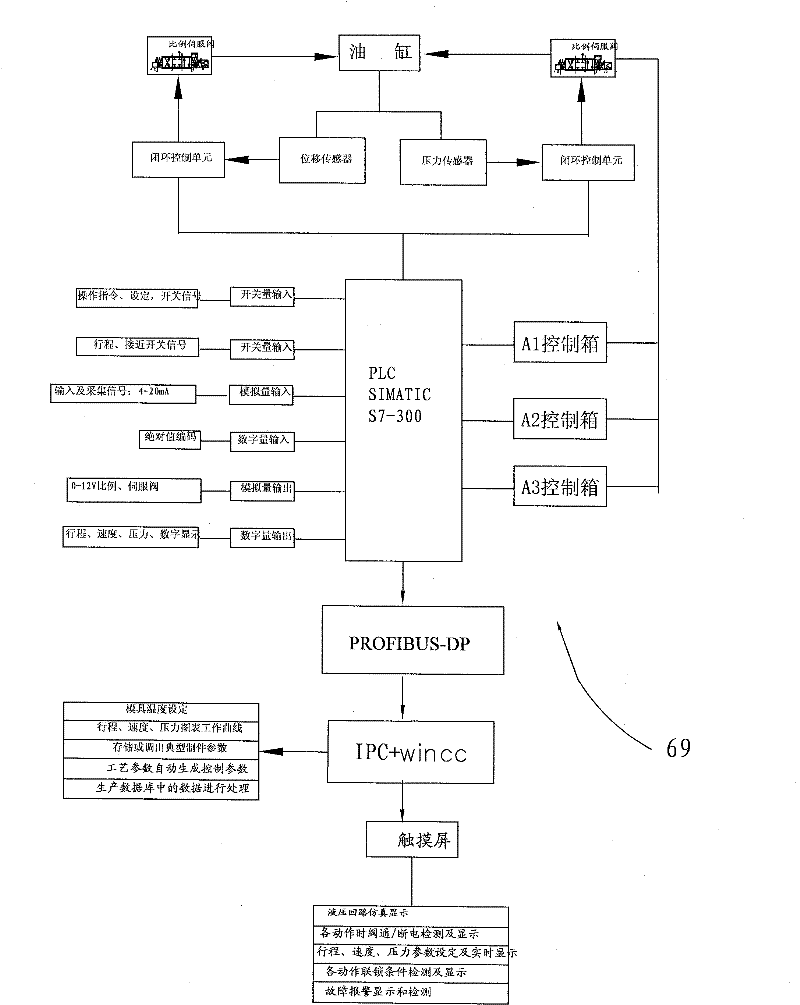

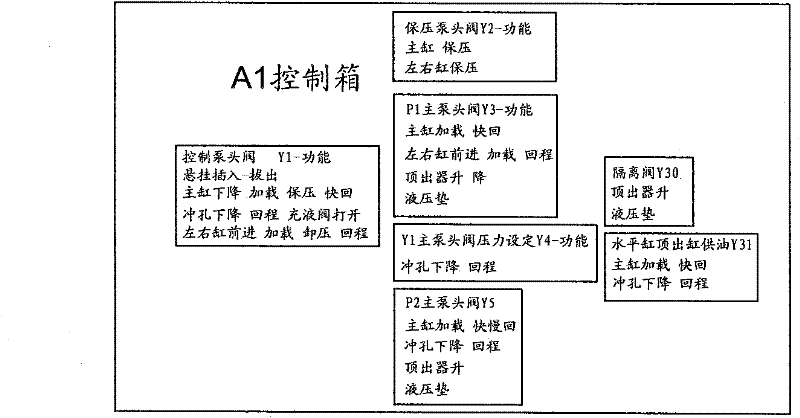

[0037] combined with Figure 1 to Figure 12 The present invention is described in further detail.

[0038] Such as figure 1 As shown, the present invention mainly includes a vertical main working cylinder 2, a left horizontal cylinder 3, a right horizontal cylinder 4 and an ejection cylinder 5 installed on a stressed frame 1.

[0039]The stress frame 1 is welded by high-strength steel plates, including two main stress plates 16 with "mouth" shapes on the front and rear, upper beams 11, lower beams 15, box-shaped columns 13; upper beams 11 and lower beams 15 are placed horizontally up and down, and the box-shaped columns are located between the upper beam 11 and the lower beam 15, one on the left and one on the left and right, and the main force plate 16 covers the front and rear sides, leaving a "mouth" shaped window. A workbench 14 is fixed above the lower beam 15 of the stressed frame 1 .

[0040] The vertical main working cylinder 2 is a special piston-type double-acting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com