Ultra-precise rapid-cutting-combination machining-forming method for optical complex curved surface of brittle material

A complex surface, fast cutting technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of easy embedding of abrasives, low processing efficiency, optical function failure, etc., to ensure performance, improve processing efficiency and cutting stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

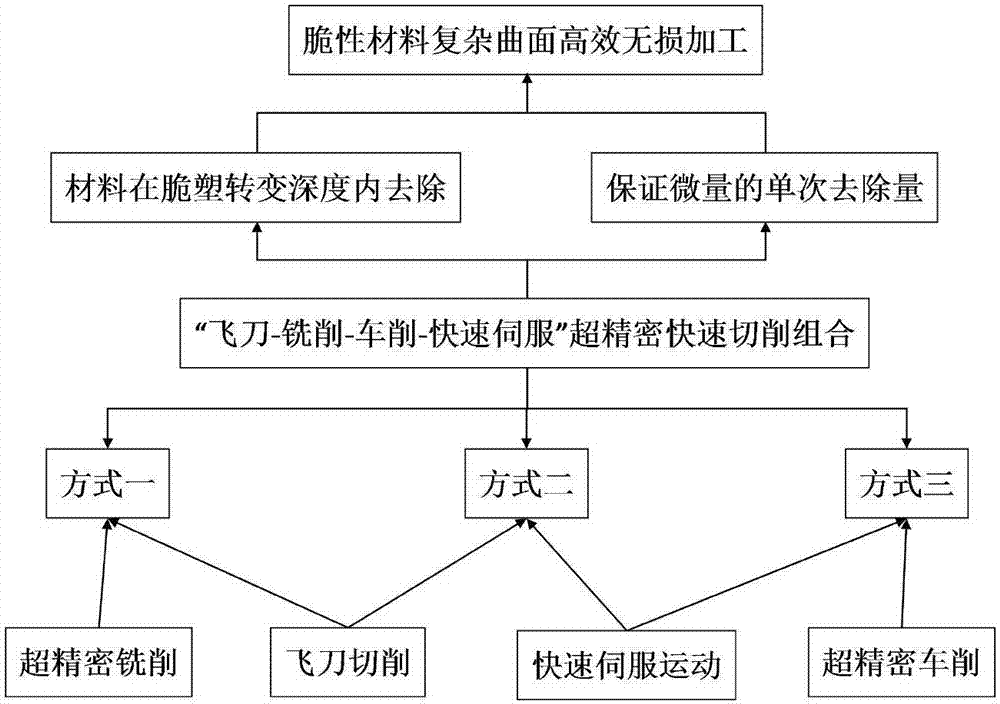

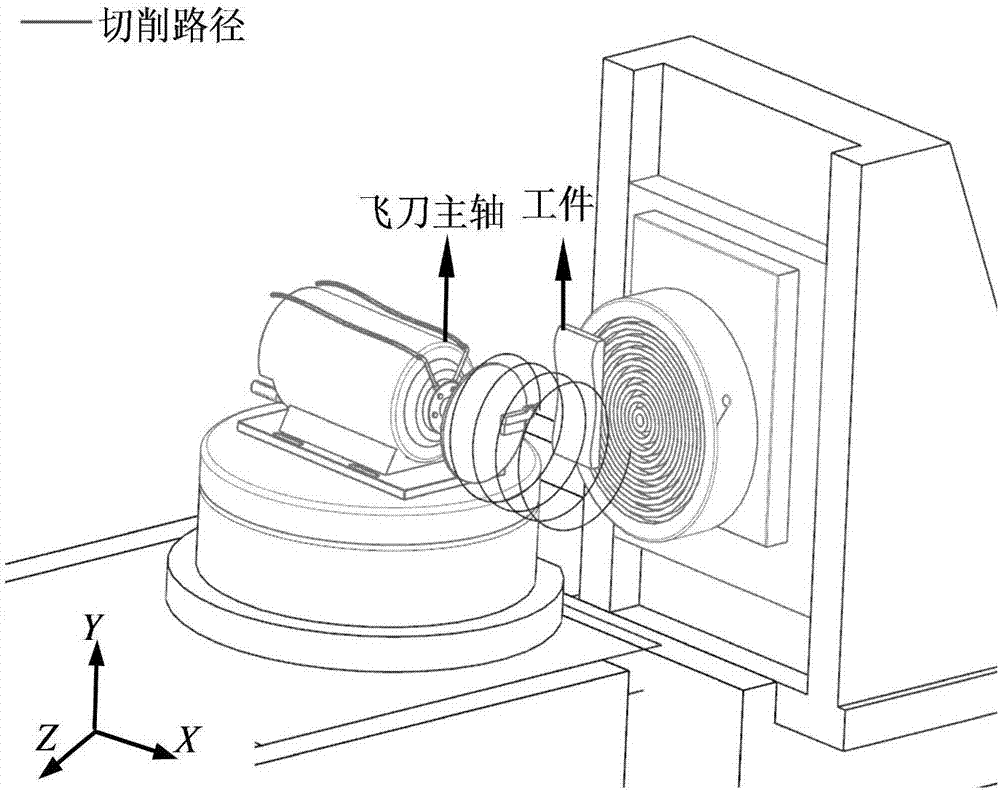

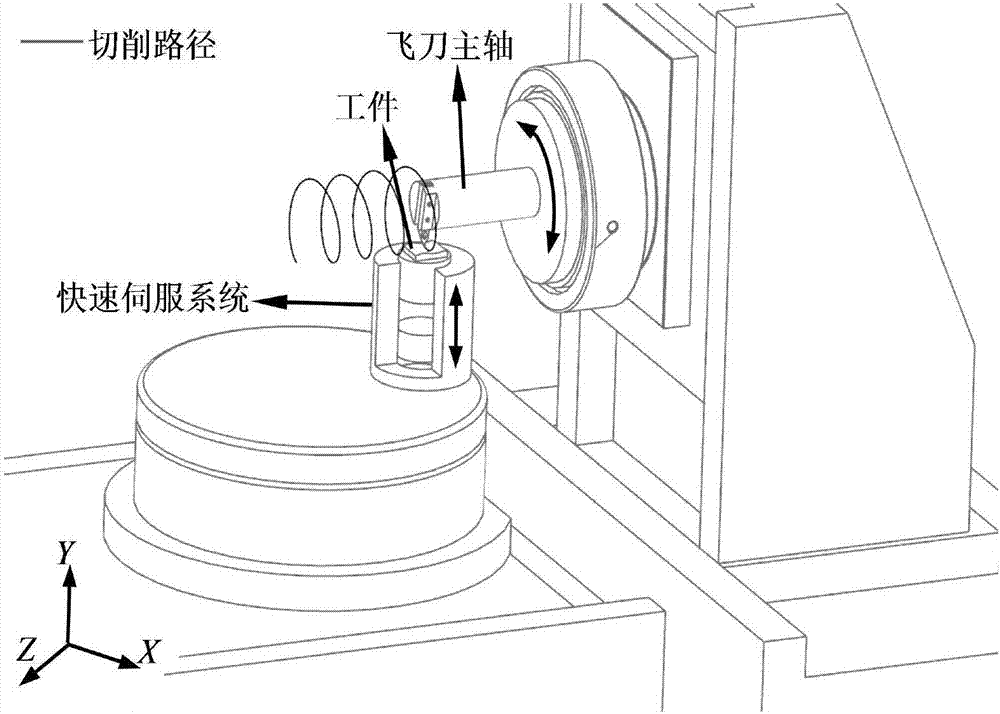

[0023] The invention proposes the combination of "flying cutter-milling-turning-fast servo" ultra-precision fast cutting to realize the processing of complex curved surfaces of brittle materials, which overcomes the contradiction and conflict between the surface quality of complex curved surfaces and the processing performance of brittle materials in the processing process. Difficulty, it guarantees the performance of complex curved surfaces very well. Due to the combined effect of multiple cutting methods, different fast cutting methods can be selected according to the shape characteristics of complex curved surfaces to be processed, and this idea is effectively used for low-damage cutting of brittle materials. The specific implementation is as follows:

[0024] 1. According to the characteristics of the complex surface, calculate the non-rotation and curvature of the surface shape, and choose the "flying knife-milling-turning-fast servo" ultra-precision fast cutting combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com