Split die vacuum bag-autoclave forming method of irregular composite material

A technology of autoclave forming and composite materials, which is applied in the field of mold-closing vacuum bag-autoclave forming of special-shaped composite materials, and achieves the effect of accurate appearance size and shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

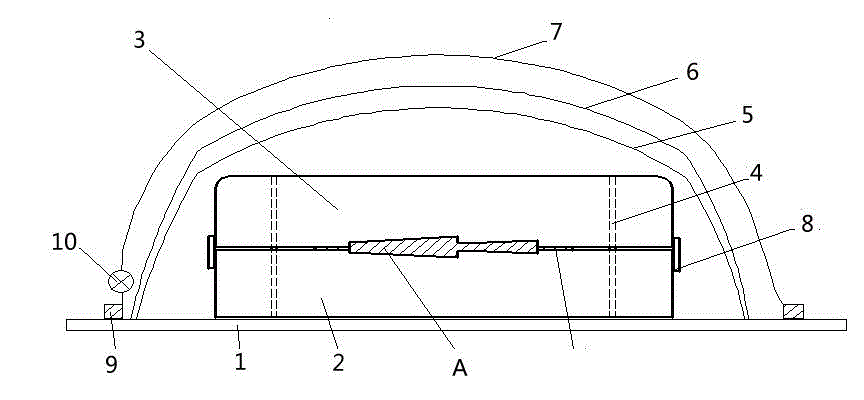

[0016] attached figure 1 It is a structural schematic diagram of the mold-matching vacuum bag-autoclave molding method of the special-shaped composite material of the present invention. In the figure, 1 is the bottom plate, 2 is the lower mold, 3 is the upper mold, 4 is the positioning hole and the positioning pin, and 5 is the Hole isolation film, 6 is an air felt, 7 is a vacuum bag, 8 is a baffle, 9 is a sealing putty strip, and 10 is a vacuum nozzle. As can be seen from the figure, the vacuum bag-autoclave molding method of the special-shaped composite material of the present invention makes a lower mold and an upper mold according to the external dimensions and shape of the composite material part to be formed, and paves the mating surfaces of the upper and lower molds A layer of raw rubber sheet, the thickness of the raw rubber layer should ensure that the thickness of the raw rubber after vulcanization plus the height of the mold cavity is equal to the thickness of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com