Preparation method of freeze-dried mango blocks

A mango block and freeze-drying technology, which is applied in the field of food processing, can solve the problems of inconvenient consumption of freeze-dried mango powder, and achieve the effect of maintaining color and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

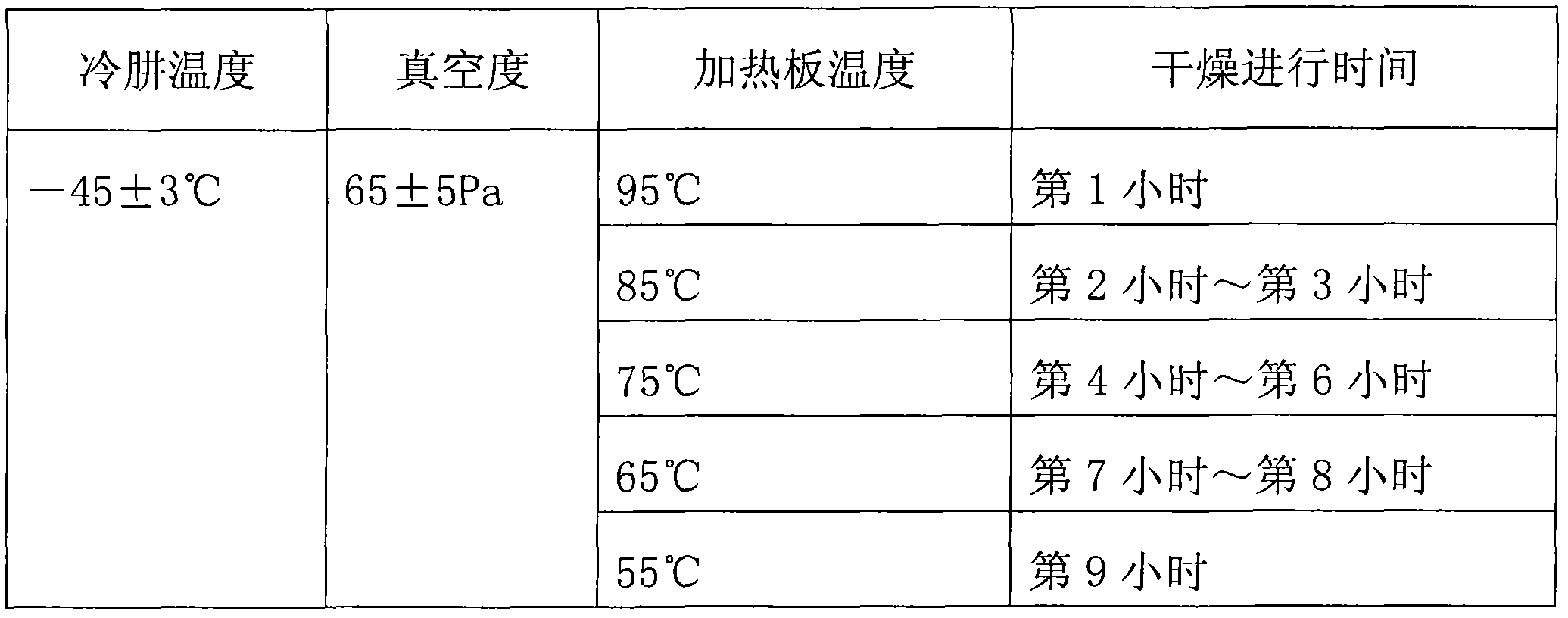

[0010] Put 500kg of fresh mangoes with a maturity of 70% and no pests and diseases into 0.2g / L sodium hypochlorite solution for 15 minutes, then wash them with drinking water; then beat the mangoes with a beater to adjust the acidity of the mango pulp to PH=4.5 , sweetness (calculated by white granulated sugar) 15%, consistency (calculated by relative density) 1.16g / ml, heated to 85°C, kept for 6 minutes, and quickly cooled to room temperature; then poured mango pulp into the mold, frozen to -20 After forming it at ℃, demould to obtain mango pieces; then put the mango pieces into the freezer to freeze to -25℃; finally put the frozen mango pieces into the drying chamber of the freeze vacuum dryer for drying treatment. For freeze-dried mango pieces, the parameter control process in the freeze-vacuum dryer is shown in Table 1.

[0011] Table 1. Parameter control in the freeze vacuum dryer

[0012]

Embodiment 2

[0014] This embodiment except adopting 0.5g / L sodium hypochlorite solution to soak mango for 8 minutes, other process steps and process conditions are all identical with embodiment 1.

Embodiment 3

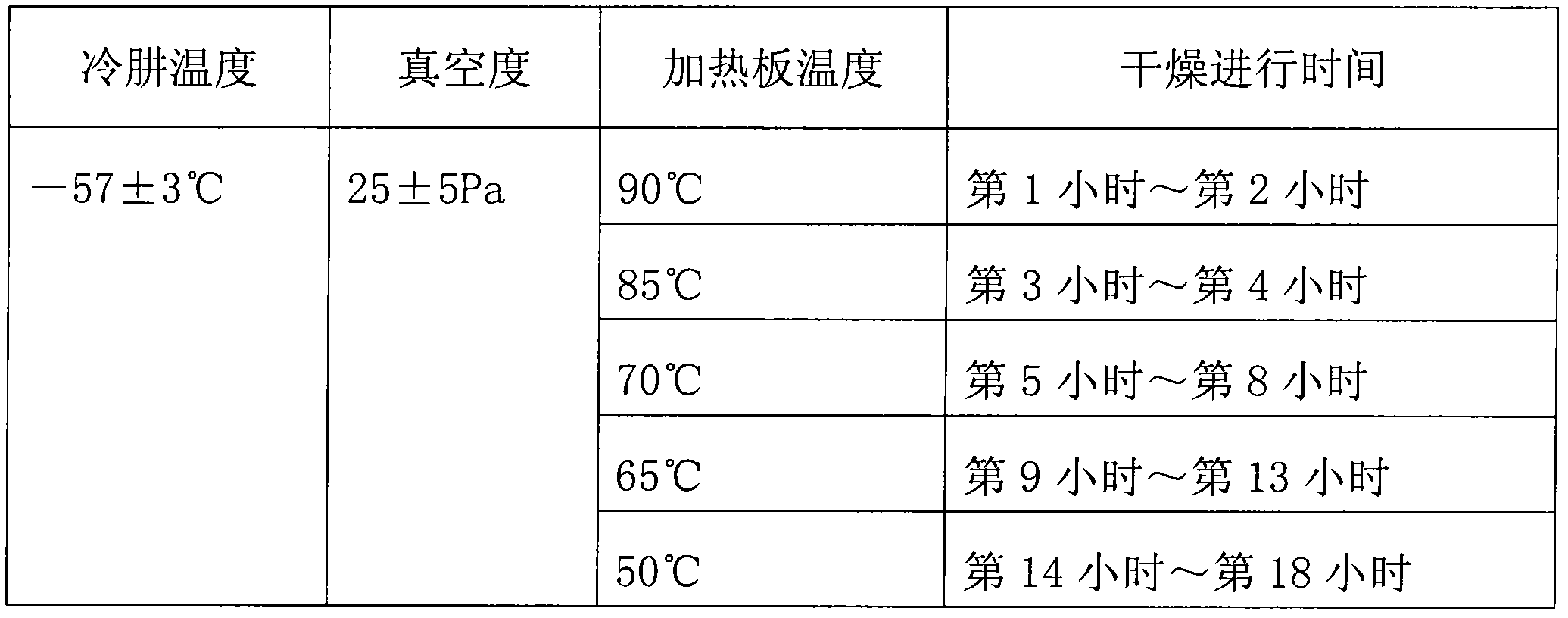

[0016] Soak 1000kg of fresh mangoes with 80% maturity and no pests and diseases in 10g / L hydrogen peroxide solution for 6 minutes, then wash them with drinking water; beat the mangoes with a beater to adjust the acidity of the mango pulp to PH=5.2 , sweetness (calculated by white sugar) 25%, consistency (calculated by relative density) 1.23g / ml, heated to 72°C, kept for 10 minutes, and rapidly cooled to room temperature; then poured mango pulp into the mold, frozen to -7 After forming it at ℃, demould to obtain mango pieces; then put the mango pieces into the freezer to freeze to -40℃; finally put the frozen mango pieces into the drying chamber of the freeze vacuum dryer for drying treatment. Freeze-dried mango pieces, the parameter control process in the freeze-vacuum dryer is shown in Table 2.

[0017] Table 2. Parameter control in the freeze vacuum dryer

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com