Method for preparing barium dititanate (BaTi2O5) ferroelectric film on silicon (Si) single crystal substrate

A ferroelectric thin film and substrate technology, applied in the field of preparing BaTi2O5 ferroelectric thin film, can solve the problems of difficult processing, unfavorable semiconductor device integration, high price of MgO single crystal substrate, etc., and achieves the effect of realizing compatibility and overcoming high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A preparation of BaTi on Si single crystal substrate 2 o 5 The method for ferroelectric thin film, it comprises the steps:

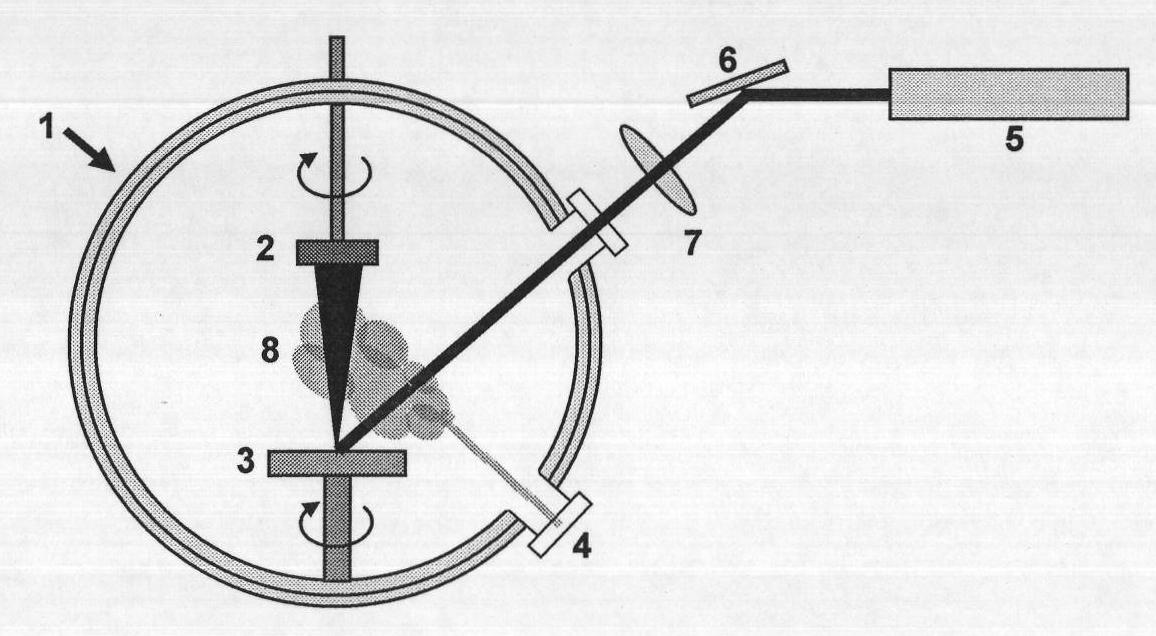

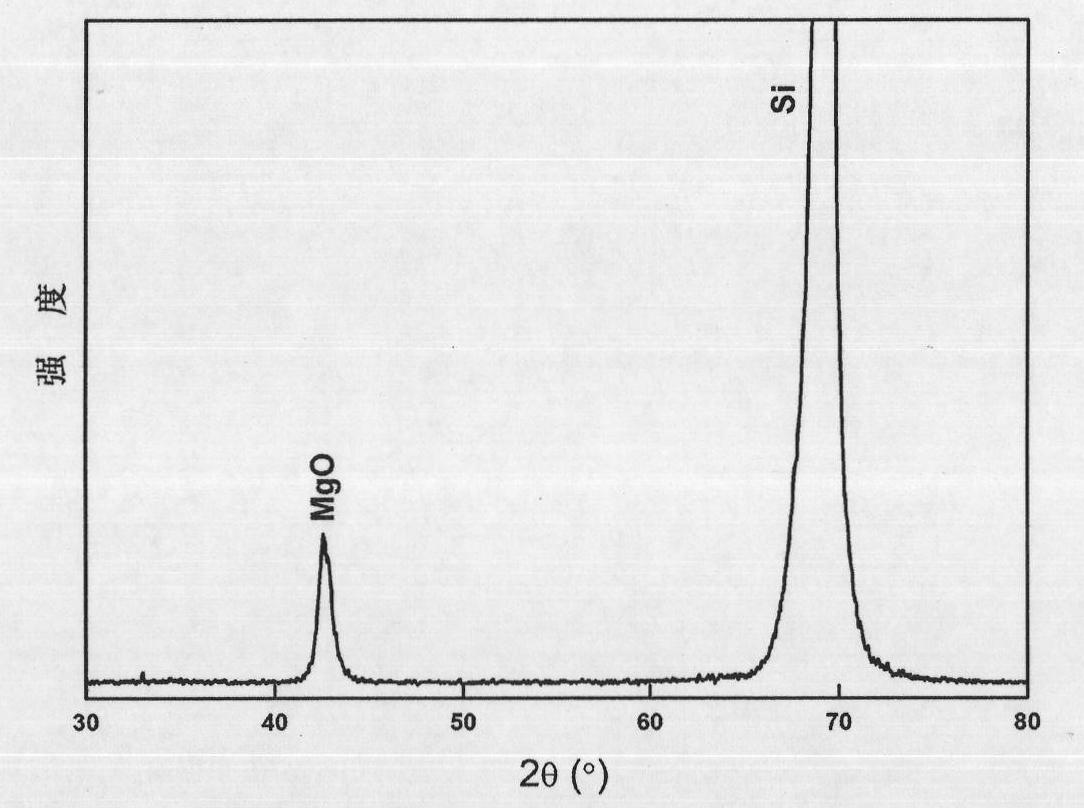

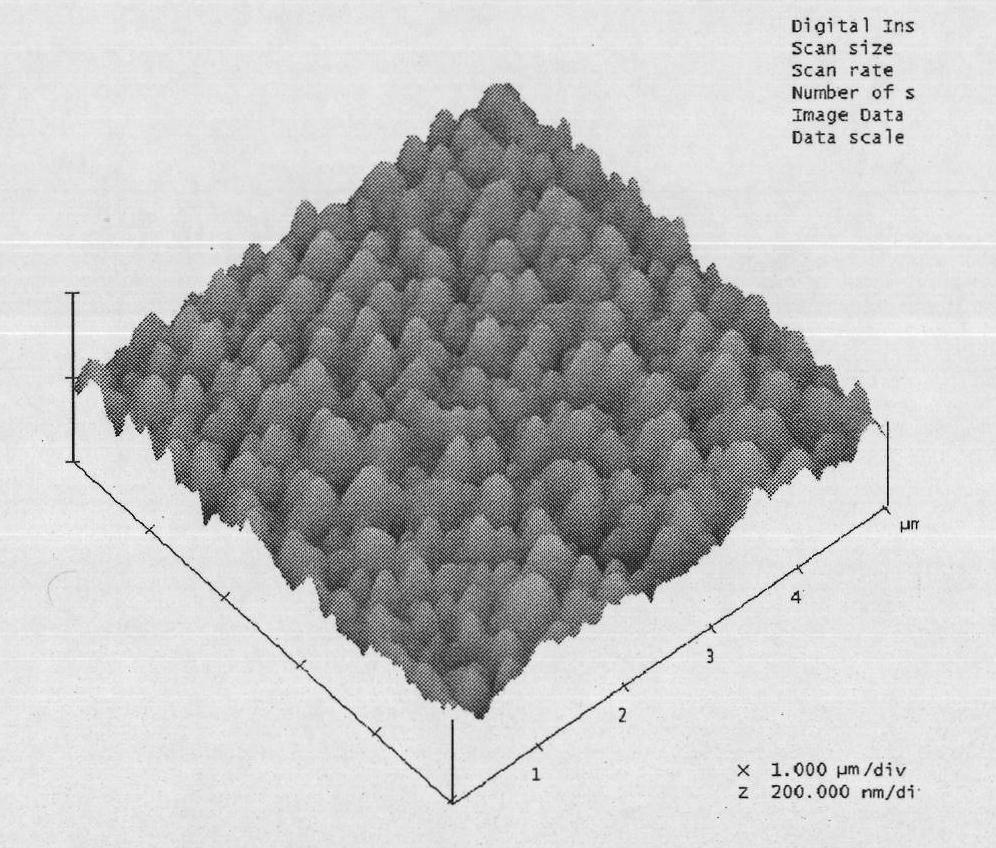

[0018] 1) The MgO film buffer layer was prepared by pulsed laser deposition technology: MgO ceramics with a purity of 98.5% and a density of 93% were used as the target material, and the substrate material was Si single crystal grown along the a-axis direction. The experimental process was as follows: figure 1 As shown: First, the substrate 2 and the target material 3 are respectively sent into the deposition chamber 1 of the pulsed laser deposition equipment and the deposition chamber 1 is evacuated to 10 -4 Pa, the substrate 2 and the target 3 are uniformly rotated at a speed of 20 rpm, and the vertical distance between them is maintained at 50mm; then, the substrate 2 is heated to 400°C, and the high-power pulse generated by the laser 5 Laser beam (laser energy density 3.5J / cm 2 ) is irradiated on the surface of the target 3 after being focu...

Embodiment 2

[0023] A preparation of BaTi on Si single crystal substrate 2 o 5 The method for ferroelectric thin film, it comprises the steps:

[0024] 1) The MgO thin film buffer layer was prepared by pulsed laser deposition technology: MgO ceramics with a purity of 99% and a density of 91% were used as the target material, and the substrate material was Si single crystal grown along the a-axis direction. respectively into the deposition chamber of the pulsed laser deposition equipment and vacuumize the deposition chamber to 10 -5 Pa, the substrate and the target are rotated uniformly at a speed of 20 rpm, and the vertical distance between the two is kept at 50mm; then, the substrate is heated to 300°C, and oxygen with a purity of 99.99% is introduced to ensure the deposition chamber. The oxygen pressure is 0.1Pa; then the energy density is 3J / cm 2 The pulsed laser beam is irradiated on the target surface to ablate the target surface at high temperature and further generate a high-temp...

Embodiment 3

[0027] A preparation of BaTi on Si single crystal substrate 2 o 5 The method for ferroelectric thin film, it comprises the steps:

[0028] 1) The MgO thin film buffer layer was prepared by pulsed laser deposition technology: MgO ceramics with a purity of 98.7% and a density of 95% were used as the target material, and the substrate material was Si single crystal grown along the a-axis direction. respectively into the deposition chamber of the pulsed laser deposition equipment and vacuumize the deposition chamber to 10 -4 Pa, the substrate and the target are rotated uniformly at a speed of 20 rpm, and the vertical distance between the two is kept at 50mm; then, the substrate is heated to 450°C, and oxygen with a purity of 99.999% is introduced to ensure the deposition chamber. The oxygen pressure is 1Pa; then the energy density is 4J / cm 2 The pulsed laser beam is irradiated on the target surface to ablate the target surface at high temperature and further generate a high-tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com