Haydite used as conductive concrete aggregate and preparation thereof

A technology of conductive concrete and aggregate, applied in the field of building materials, can solve problems such as difficulties, uneven distribution of concrete materials, affecting the uniform distribution of conductive network, etc., to achieve the effects of enhancing conductive performance, reducing dosage and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of ceramsite used as conductive concrete aggregate, which is composed of clay, iron powder, coke powder and Fe 2 o 3 It is fired from raw materials, and the mass percentage of each raw material is: clay 90%, iron powder 5%, coke powder 3%, Fe 2 o 3 2%.

[0028] Above-mentioned a kind of preparation method as the ceramsite of conductive concrete aggregate, it comprises the steps:

[0029] 1) Raw material pretreatment: Dry the clay (ordinary clay) taken from the soil until the moisture content is 4% (mass), grind it into a fine powder after crushing, and pass through a 0.075mm sieve; crush and grind commercially available coke , through a 0.075mm sieve to obtain coke powder;

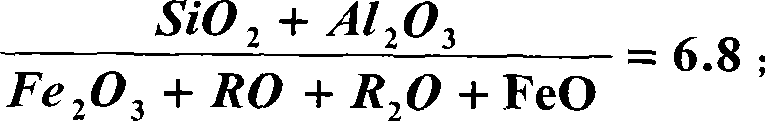

[0030] The chemical composition of clay is SiO 2 + Al 2 O 3 Fe ...

Embodiment 2

[0043] A kind of ceramsite used as conductive concrete aggregate, which is composed of clay, iron powder, coke powder and Fe 2 o 3 It is fired from raw materials, and the mass percentage of each raw material is: clay 84%, iron powder 7%, coke powder 4%, Fe 2 o 3 5%.

[0044] Above-mentioned a kind of preparation method as the ceramsite of conductive concrete aggregate, it comprises the steps:

[0045] 1) Raw material pretreatment: drying the clay (ordinary clay) taken from the soil until the moisture content is 5% (mass), crushing and grinding into fine powder, passing through a 0.075mm sieve;

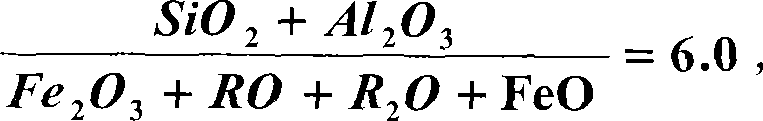

[0046] The chemical composition of clay is SiO 2 + Al 2 O 3 Fe 2 O 3 + ...

Embodiment 3

[0059] A preparation method of ceramsite used as conductive concrete aggregate, it comprises the steps:

[0060] 1) Raw material pretreatment: Dry the clay (ordinary clay) taken from the soil until the moisture content is 3% (mass), grind it to a powder with a particle size of ≤0.1mm after crushing; grind commercially available coke Finely grind into a powder with a particle size of ≤0.1mm to obtain coke powder;

[0061] 2) Selection of raw materials: according to the mass percentage of each raw material: clay 77%, iron powder 10%, coke powder 5%, Fe 2 o 3 8%, choose clay, iron powder, coke powder and Fe 2 o 3 as raw material, spare;

[0062] The iron powder is a commercially available industrial iron powder with a purity of ≥98% (by mass) and an average particle size of 0.005 to 0.01mm; the Fe 2 o 3 Fe is a commercially available industrial product 2 o 3 ;

[0063] 3) Embryo body forming: clay, iron powder, coke powder and Fe 2 o 3 Add water and stir in the blende...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com