Process for dispersing carbon nanotubes in electroconductive adhesive of lithium ion battery

A lithium-ion battery, carbon nanotube technology, applied in battery electrodes, circuits, electrode manufacturing, etc., can solve problems such as affecting production quality, low battery capacity, poor consistency, etc., to achieve superior overall electrical conductivity, uniform electrical conductivity, and improved The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

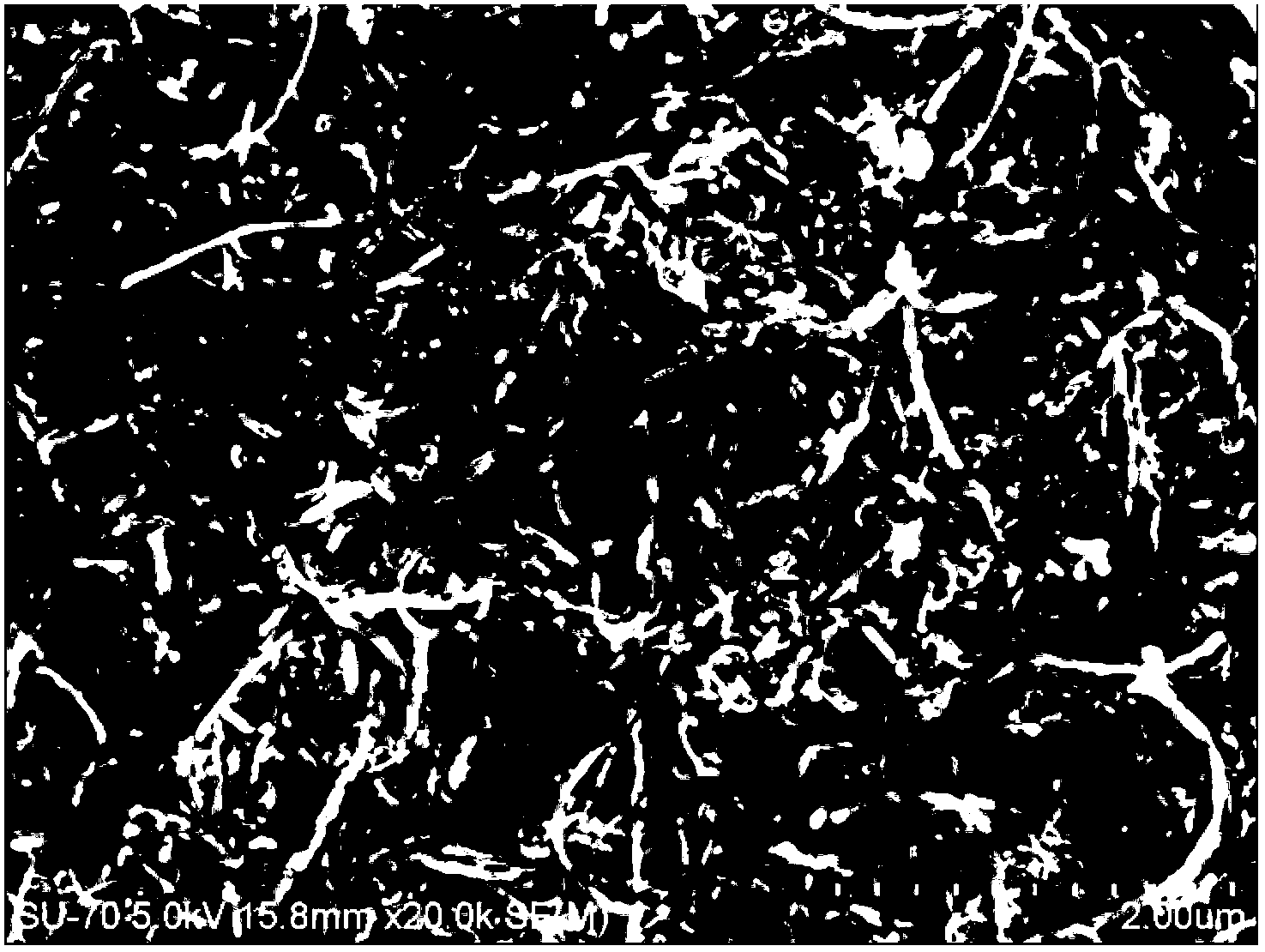

Embodiment 1

[0036] CNT (carbon nanotube) is used as the conductive agent, KD-1 (hyperdispersant for lithium-ion batteries, available from British Croda Company) and PVP (polyvinylpyrrolidone) with a mass ratio of 1:8 are used as the dispersant, PVDF (Polyvinylidene fluoride) as the binder, NMP (nitromethylpyrrolidone) as the solvent, and add LiFePO with a D50 of 0.4~0.8um 4 (lithium ferrous phosphate), Li with D50 of 0.9~2um 4 Ti 5 o 12 (lithium titanate) and Al with D50 of 2~20um 2 o 3 (Al2O3), in which the mass ratio of conductive agent, dispersant, lithium iron phosphate, lithium titanate, aluminum oxide and solvent is: 1.5:0.2:2:0.5:0.5:95; glue.

[0037] The conductive adhesive preparation process is as follows:

[0038] (1) Mix and stir the conductive agent, dispersant and solvent according to the conventional method to make it fully wet; then, add lithium iron phosphate, lithium titanate, and aluminum oxide, and mix and stir for 30 minutes according to the existing technology...

Embodiment 2

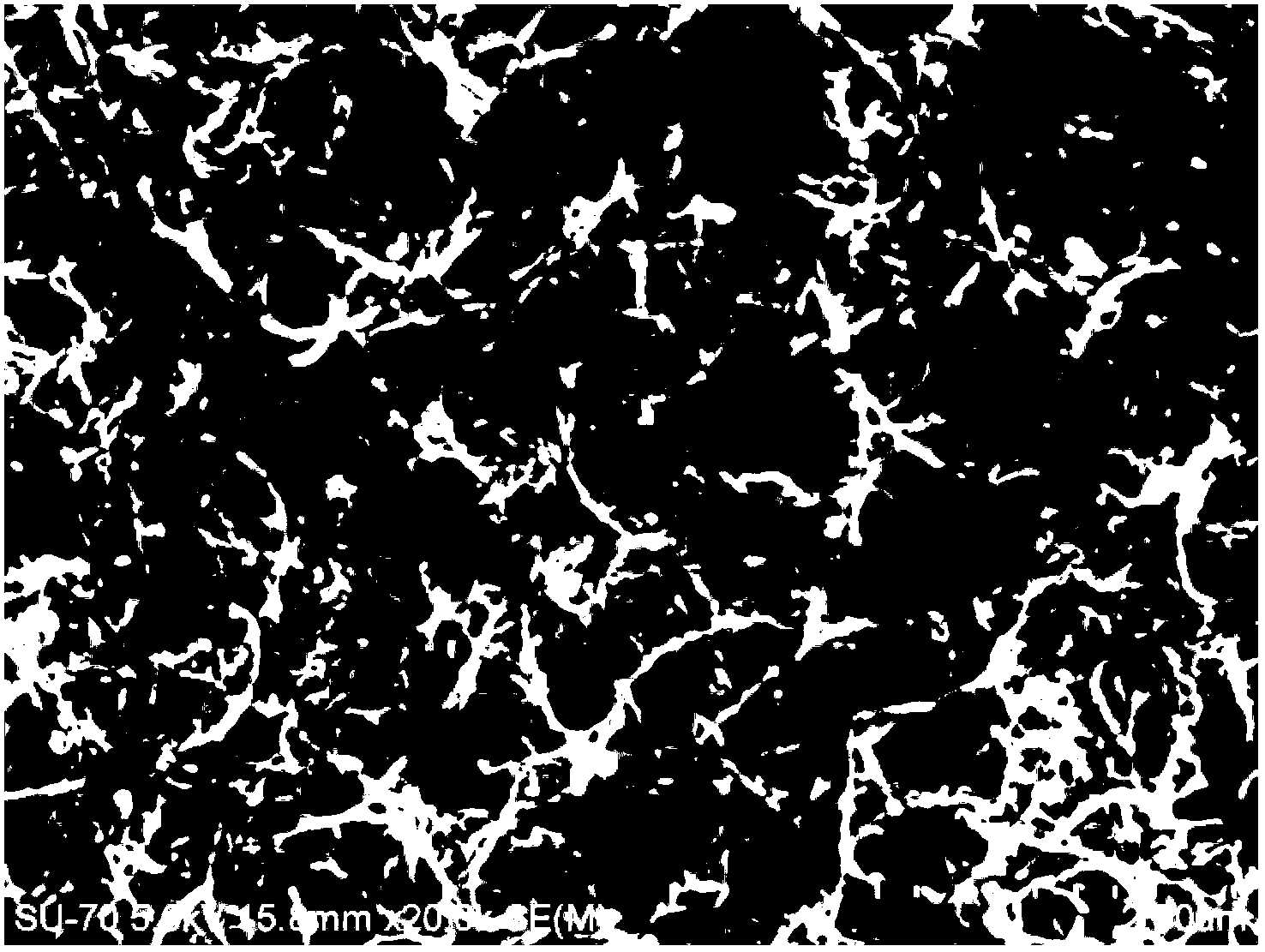

[0043]Using CNT (carbon nanotube) as the conductive agent, KD-1 (hyperdispersant for lithium-ion batteries, available from Croda, UK) and PVP (polyvinylpyrrolidone) with a mass ratio of 1:1 as the dispersant, PVDF (Polyvinylidene fluoride) as the binder, NMP (nitromethylpyrrolidone) as the solvent, and add LiFePO with a D50 of 0.4~0.8um 4 (lithium ferrous phosphate), Li with D50 of 0.9~2um 4 Ti 5 o 12 (lithium titanate) and Al with D50 of 2~20um 2 o 3 (Al2O3), in which the mass ratio of conductive agent, dispersant, lithium iron phosphate, lithium titanate, aluminum oxide, and solvent is 2:0.6:3:1:1:125, and it is prepared into a conductive adhesive .

[0044] The conductive adhesive preparation process is as follows:

[0045] (1) Mix and stir the conductive agent, dispersant and solvent according to the conventional method to make it fully wet; then, add lithium iron phosphate, lithium titanate and aluminum oxide, and mix and stir for 50 minutes according to the existin...

Embodiment 3

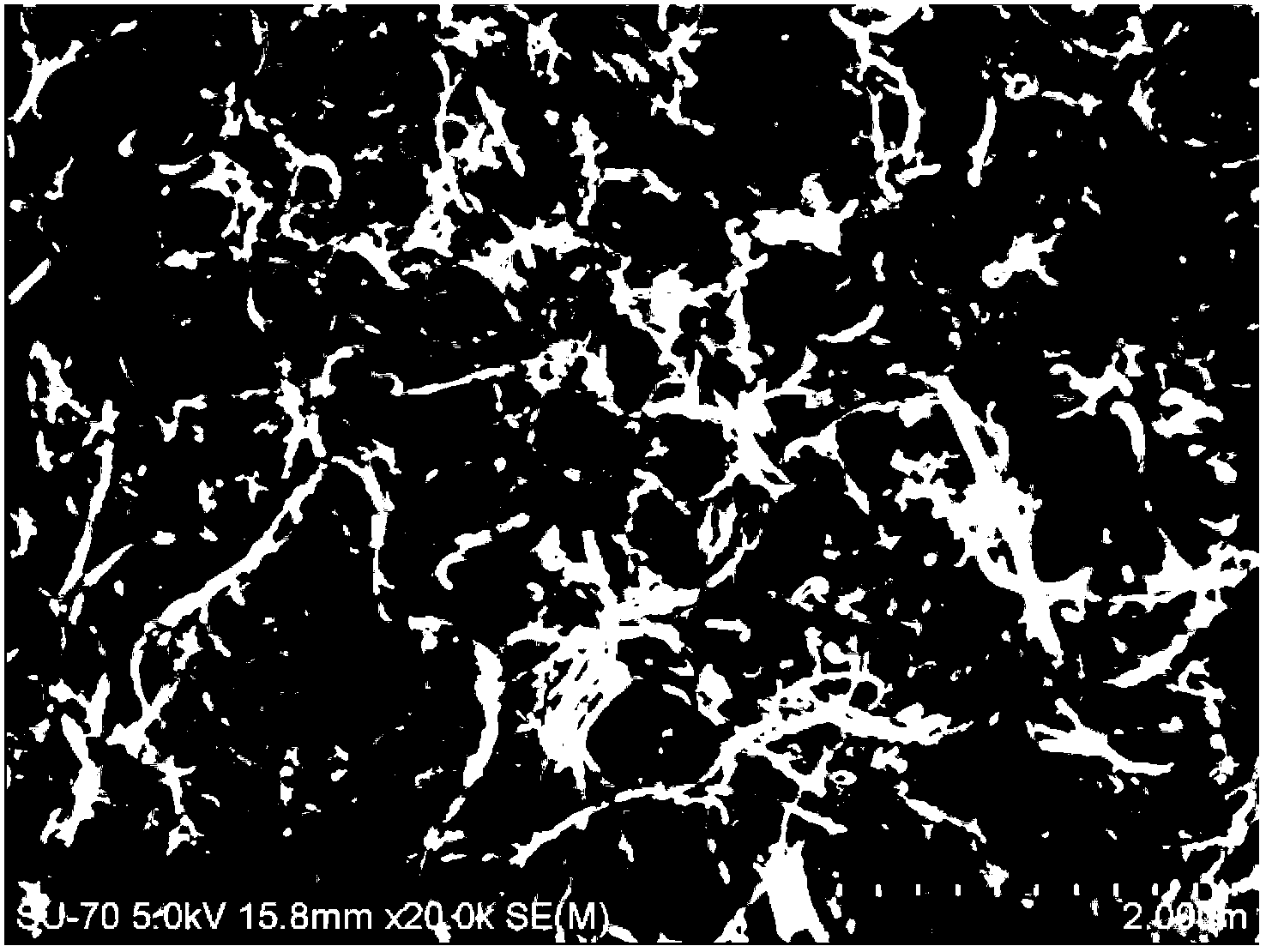

[0050] CNT (carbon nanotube) is used as the conductive agent, and KD-1 (hyperdispersant for lithium-ion batteries, available from British Croda Company) and PVP (polyvinylpyrrolidone) with a mass ratio of 8:1 are used as the dispersant, PVDF (Polyvinylidene fluoride) as the binder, NMP (nitromethylpyrrolidone) as the solvent, and add LiFePO with a D50 of 0.4~0.8um 4 (lithium ferrous phosphate), Li with D50 of 0.9~2um 4 Ti 5 o 12 (lithium titanate) and Al with D50 of 2~20um 2 o 3 (Al2O3), in which the mass ratio of conductive agent, dispersant, lithium iron phosphate, lithium titanate, aluminum oxide, and solvent is 3:1.6:5:2:2:150, and the ratio of adhesive The amount added accounts for 3.53% of the mass of the conductive adhesive, and it is formulated into a conductive adhesive.

[0051] The conductive adhesive preparation process is as follows:

[0052] (1) Mix and stir the conductive agent, dispersant and solvent according to the conventional method to make it fully w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com