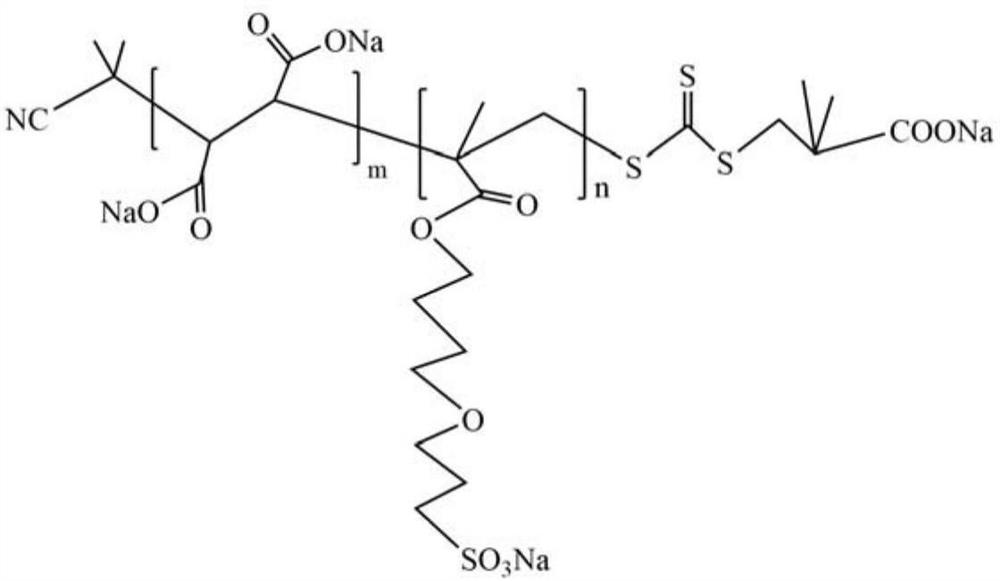

A sulfonic acid type block copolymer aqueous dispersant of raft technology

A block copolymer and water-based dispersant technology, applied in the field of sulfonic acid-type block copolymer water-based dispersants, can solve the problems of unstable dispersion performance and high molecular weight polydispersity coefficient of synthetic dispersants, and achieve good compatibility, Large adsorption capacity and high dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

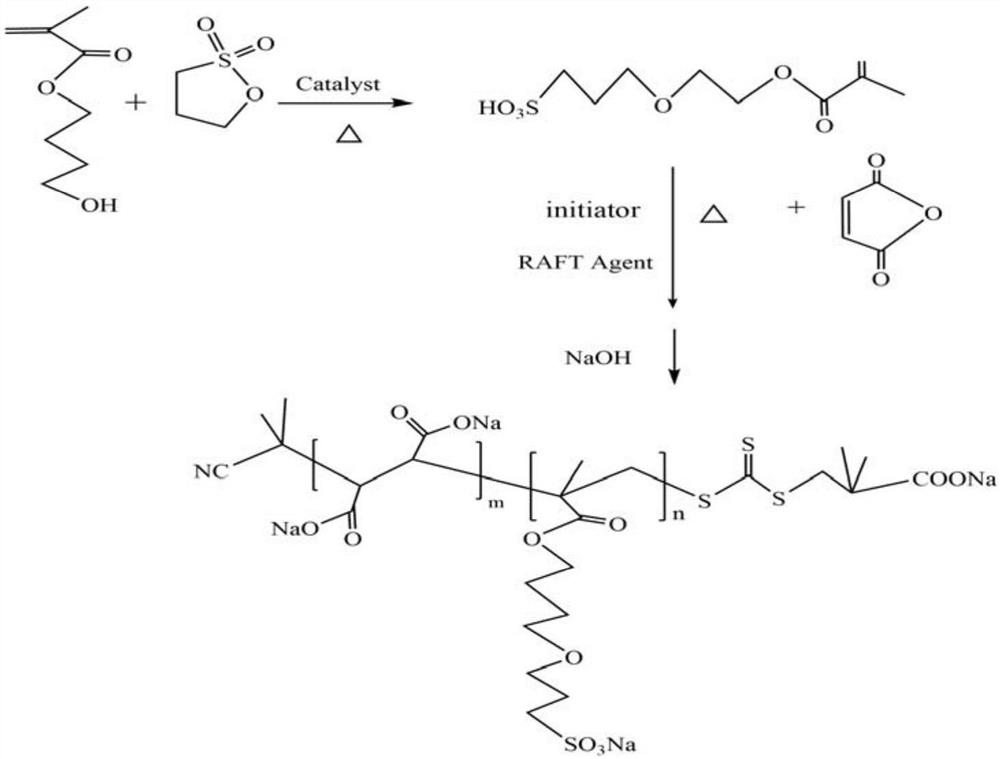

Method used

Image

Examples

Embodiment 1

[0026] A kind of sulfonic acid type block copolymer aqueous dispersant of RAFT technology, its steps are as follows:

[0027] a) According to the weight ratio of the formula, add dimethyl sulfoxide, hydroxybutyl acrylate, and 1,3-propane sultone into the reaction kettle in sequence, start stirring to dissolve evenly, heat to 65°C for 7 hours, and cool to Add methanol to dissolve at 40°C, then add acetone to precipitate, suction filter the precipitate, then dissolve with methanol, precipitate with acetone, and suction filter, repeat 2 to 3 times to obtain vinyl monomer I containing sodium sulfonate group; , the molar ratio of hydroxybutyl acrylate to 1,3-propane sultone is 1.3:1;

[0028] b), at N 2 In the protected reaction kettle, add 15.0 parts of maleic anhydride, 0.8 parts of diethyldithiocarbamate quaternary ammonium salt, and 45.0 parts of ethanol in sequence. After stirring and dissolving, heat up to 80°C and evenly add 10.0 parts of One part of ethanol solution conta...

Embodiment 2

[0030] A kind of sulfonic acid type block copolymer aqueous dispersant of RAFT technology, its steps are as follows:

[0031] a) According to the weight ratio of the formula, add butanone, hydroxyethyl methacrylate, and 1,4-butane sultone into the reaction kettle in sequence, start stirring and dissolving evenly, heat to 90°C for 6 hours, and cool to 40°C Add methanol to dissolve at ℃, then add acetone to precipitate, filter the precipitate, dissolve with methanol, precipitate with acetone, and filter with suction, repeat 2 to 3 times to obtain vinyl monomer I containing sodium sulfonate group; among them, The molar ratio of the hydroxyethyl methacrylate to 1,4-butane sultone is 1:1;

[0032] b), at N 2In the protected reaction kettle, add 20.0 parts of maleic anhydride, 0.5 parts of α-dithiobenzyl p-benzylidene pyridinium chloride, and 50.0 parts of water in sequence. After stirring and dissolving, heat up to 90°C. Evenly add 12.0 parts of ethanol solution containing 10% az...

Embodiment 3

[0034] A kind of sulfonic acid type block copolymer aqueous dispersant of RAFT technology, its steps are as follows:

[0035] a) According to the weight ratio of the formula, add dimethylformamide, hydroxypropyl methacrylate, and 3-methyl-1,3-propane sultone into the reaction kettle in sequence, start stirring to dissolve evenly, and heat to React at 70°C for 6 hours, cool to 40°C and add methanol to dissolve, then add acetone to precipitate, filter the precipitate, then dissolve with methanol, precipitate with acetone, and filter with suction, repeat 2 to 3 times to obtain sodium sulfonate group Vinyl monomer I; wherein, the molar ratio of hydroxypropyl methacrylate to 3-methyl-1,3-propane sultone is 1.2:1;

[0036] b), at N 2 In the protected reaction kettle, add 20.0 parts of maleic anhydride, 2.0 parts of dithiophenylacetic acid, and 60.0 parts of ethanol in sequence. After stirring and dissolving, heat up to 100°C and evenly add 15.0 parts of 10% azobisisobutyl The etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com