Environment-friendly waterborne block copolymer dispersant and preparation method thereof

The technology of a block copolymer and a dispersant is applied in the field of environmental protection water-based block copolymer dispersant and its preparation, which can solve the problem that the hydrophilic group cannot produce a stabilizing effect, the pigment dispersion system is difficult to exist stably, and the coating protective layer is chemically resistant. problems such as poor performance, achieving low critical micelle concentration, avoiding macroscopic phase separation, and stabilizing the phase state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present application will be described in further detail below in conjunction with specific embodiments. It should be understood that the following exemplary embodiments and descriptions are only used to explain the present invention, not as a limitation to the present invention, and, in the case of no conflict, the embodiments in the application and the features in the embodiments can be combined with each other .

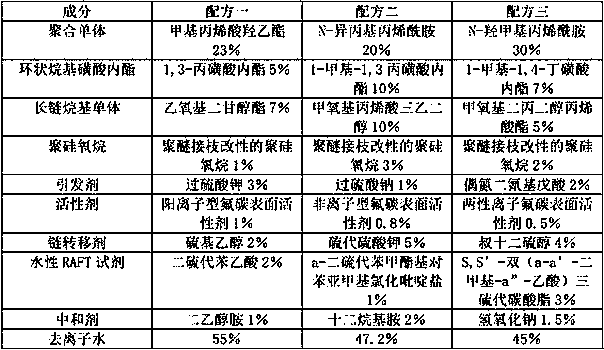

[0037] Embodiments of the present invention provide an environmentally friendly water-based block copolymer dispersant, the raw materials of which include the following components in mass percent:

[0038] Polymerized monomer 20-30%;

[0039] Cyclic alkyl sultone 5-10%;

[0040] Long-chain alkyl monomer 5-10%;

[0041] Polysiloxane 1-3%;

[0042] Initiator 1~3%;

[0043] Active agent 0.5~1%;

[0044] Chain transfer agent 2-5%;

[0045] Water-based RAFT reagent 1-3%;

[0046] Neutralizer 1-2%; and

[0047] 45-55% deionized water.

[0048] Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com