Powder surface metallization method and device

A surface metallization device technology, applied in the field of powder surface metallization method and device, can solve the problems of surface roughness, agglomeration, leakage plating, etc., and achieve the effect of uniform plating and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

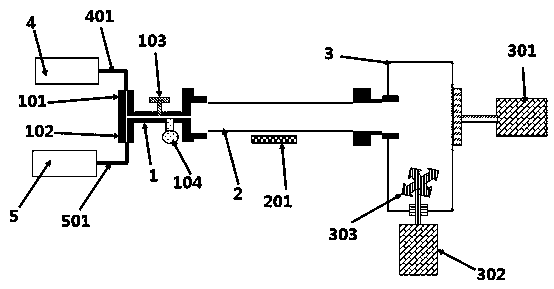

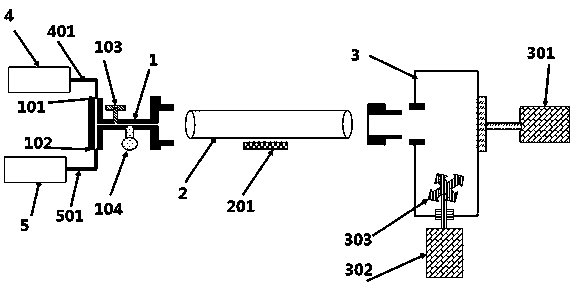

[0026] The embodiment of the present invention will be described in detail in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation and specific operation process, but the scope of protection of the present invention is not limited to the following embodiments.

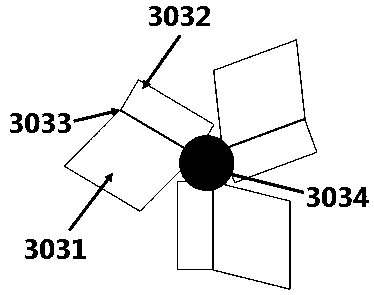

[0027] According to the accompanying drawings, the present invention is mainly used for metallizing the surface of fine-grained powders (average diameter less than 12 microns, or D50 less than 10 microns); a powder surface metallization device, which includes an air-inducing pipe 1, a heating pipe 2. The heater 201 and the dispersing device, the air induction pipe 1, the heating pipe 2 and the dispersing device are sequentially arranged in the horizontal direction, the heater 201 is arranged below the heating pipe 2, and the One end of the air-inducing pipe 1 is provided with an air inlet 101 and an air suction port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com