A kind of preparation method of flexible self-supporting electrochromic film

An electrochromic, self-supporting technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of device performance impact, poor conductivity of NiO materials, etc., and achieve the effect of improving conductivity, overcoming bonding resistance, and realizing bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

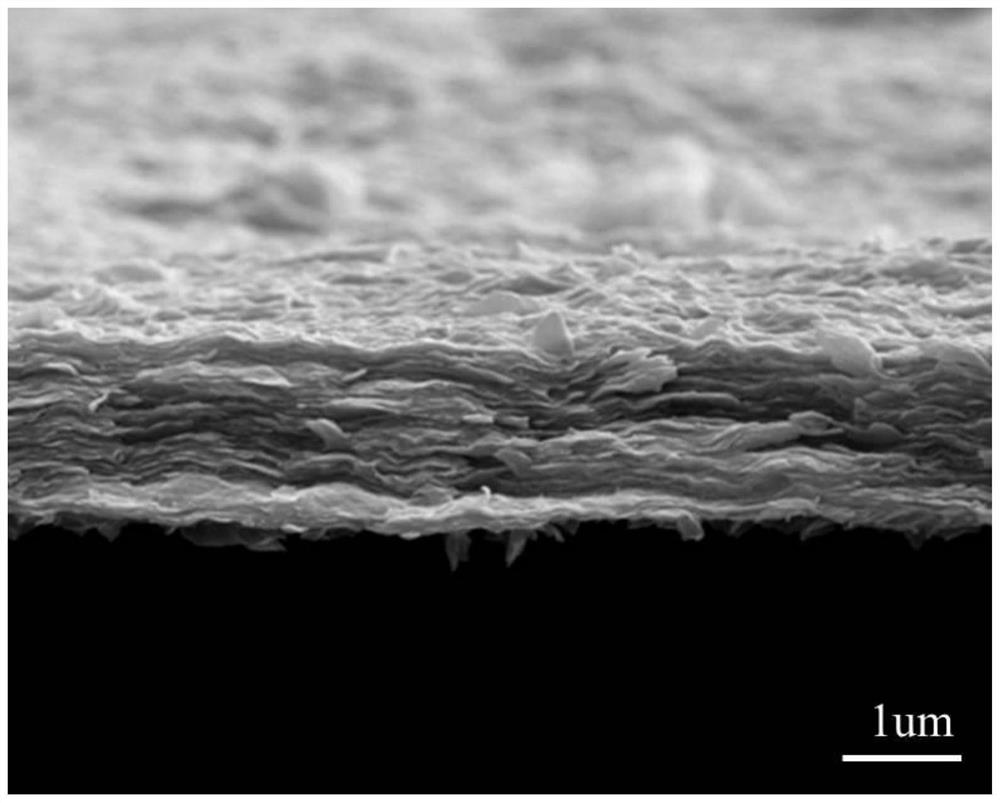

[0024] Embodiment 1: This embodiment is a method for preparing a flexible self-supporting electrochromic film, which is specifically carried out according to the following steps:

[0025] 1. Clean the encapsulation layer and the conductive layer: ultrasonically clean the PET film and the PET-ITO film respectively, and then vacuum-dry them at 60°C to 70°C; Ultrasound for 10min to 12min each;

[0026] 2. Preparation of nickel hydroxide dispersion: Mix nickel nitrate, sodium dodecylbenzenesulfonate and hexamethylenetetramine in deionized water, stir for 1h to 1.5h, then transfer to polytetrafluoroethylene hydrothermal In the kettle, react for 24 hours under the condition of hydrothermal reaction temperature of 95°C to 97°C, and naturally cool to room temperature to obtain dodecyl-intercalated nickel hydroxide, and the dodecyl-intercalated nickel hydroxide is respectively Wash three times each with deionized water and absolute ethanol, dry at room temperature, strip the dried dod...

specific Embodiment approach 2

[0033]Specific embodiment two: what this embodiment is different from specific embodiment one is: the nickel hydroxide of the dodecyl intercalation layer after stripping the dodecyl intercalation after the water bath method described in the step 2 with formamide as the stripping solvent is according to the following steps Carried out: Add the dried dodecyl-intercalated nickel hydroxide to formamide, and put it in a water bath at 40°C for 96h; the quality of the dried dodecyl-intercalated nickel hydroxide is the same as that of formamide The volume ratio is 5mg:4mL. Others are the same as the first embodiment.

specific Embodiment approach 3

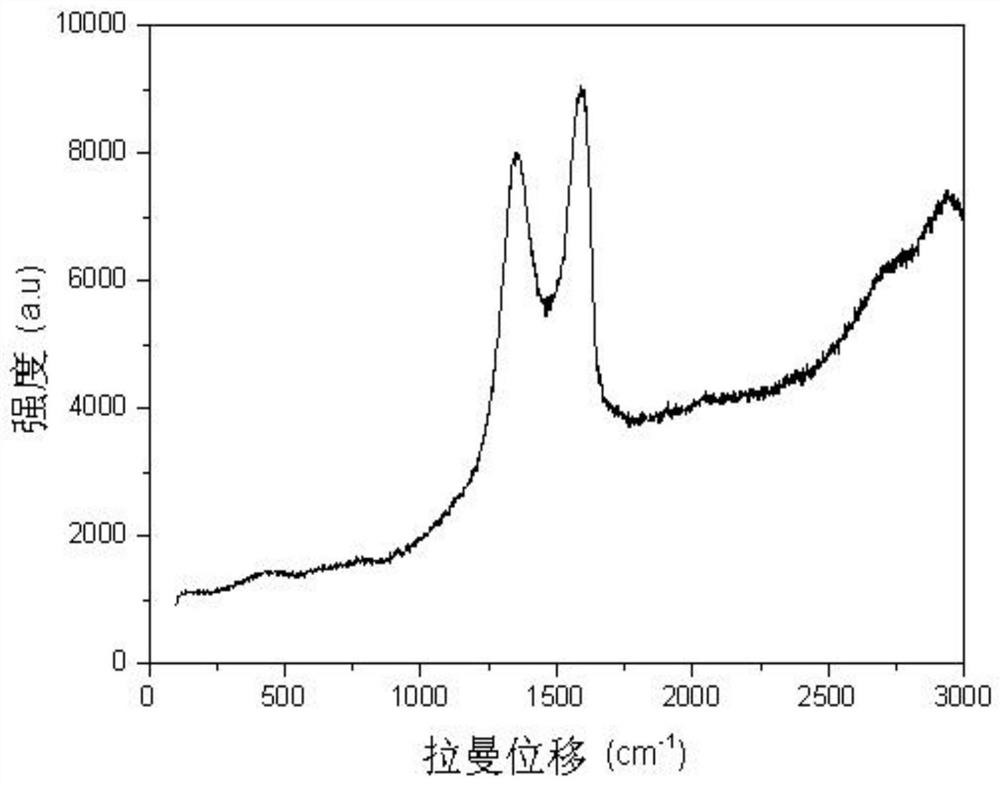

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the improved Hummers method described in step 3 is used to prepare graphene oxide according to the following steps: the concentrated sulfuric acid of 8mL is added to the Erlenmeyer flask Heating to 80°C, adding 1.7g of potassium persulfate and 1.7g of phosphorus pentoxide to dissolve, adding 2g of graphite powder and continuing the reaction at 80°C for 4.5h, cooling to room temperature, adding 100mL of deionized water, and standing 12h, filter and wash, and dry at room temperature; add the dried product into a beaker, add 50mL of concentrated sulfuric acid and stir, add 12g of potassium permanganate under ice bath conditions and continue stirring for 2h under ice bath conditions, heat to 35°C, stop heating and continue stirring for 2h, add 100mL of deionized water and continue stirring for 2h, continue to add 400mL of deionized water, drop in 5mL of hydrogen perox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com