Zinc ion driven titanium dioxide electrochromic device and preparation method thereof

An electrochromic device, titanium dioxide technology, applied in the direction of instruments, nonlinear optics, optics, etc., to achieve the effect of excellent device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

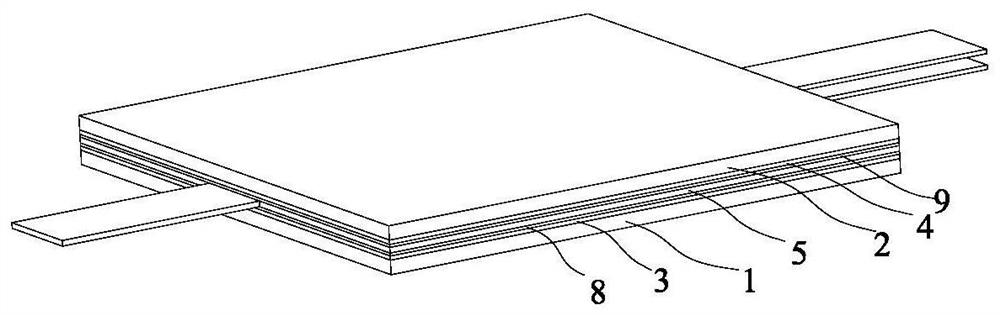

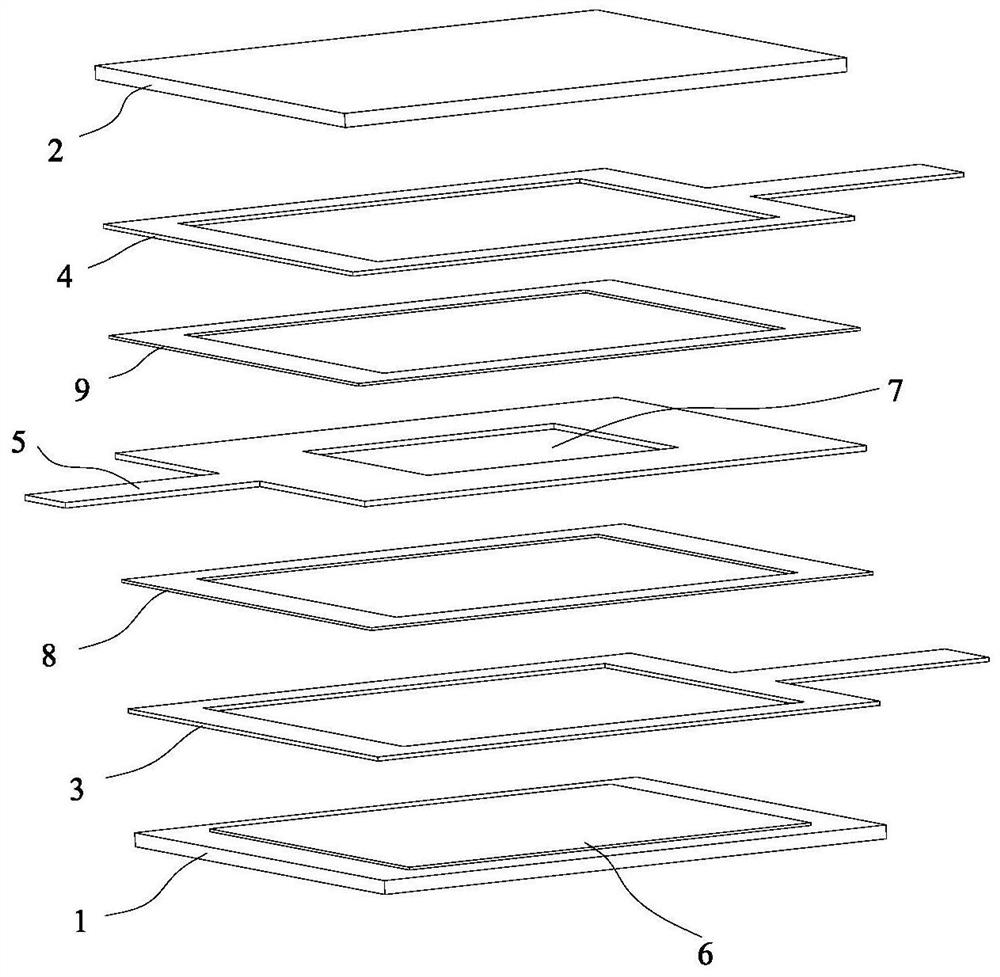

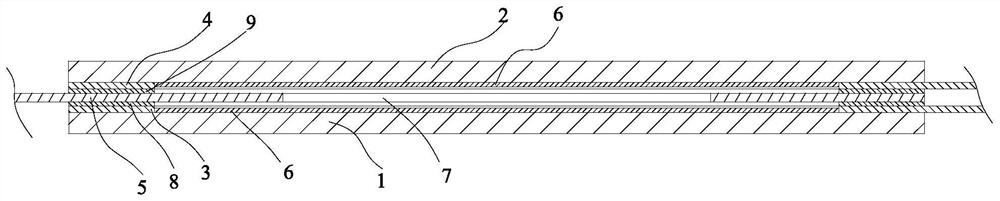

Image

Examples

preparation example Construction

[0050] The above-mentioned preparation method of zinc ion-driven titanium dioxide electrochromic device comprises the following steps:

[0051] S1. Preparation of tungsten-doped titanium dioxide solution; the tungsten-doped titanium dioxide solution prepared in this step is in a stable colloidal solution state, which is suitable for solution processing.

[0052] Specifically, the step S1 includes:

[0053] S1-1. Preparation of Ti precursor solution: mix titanium compound and octadecene and heat in an inert gas atmosphere to form a Ti precursor solution; the volume ratio of the amount of titanium compound to octadecene is 0.5- 3mol / L (specifically, the volume ratio of the amount of titanium compound and octadecene can be 0.5 or 1 or 2 or 3mol / L, etc.); the titanium compound is tetraethyl titanate or titanium tetrachloride or One or a combination of tetrabutyl titanate or isopropyl titanate; the inert gas is one or a combination of argon, nitrogen or helium; the heating tempera...

Embodiment 1

[0067] A preparation method of a zinc ion-driven titanium dioxide electrochromic device, comprising the steps of:

[0068] S1. Preparation of tungsten-doped titanium dioxide solution; including:

[0069] S1-1. Preparation of Ti precursor solution: Mix 30mmol tetraethyl titanate and 30mL octadecene, heat at 120°C for 1 hour under an inert gas atmosphere, and form a light yellow transparent oil phase solution, namely Ti precursor solution ;

[0070] S1-2. Mix 0mmol tungsten chloride, 0.5mL oleic acid, 0.5mL oleylamine, 8mL octadecene, 15mg ammonium fluoride, 2.7g stearyl alcohol and 1mL Ti precursor solution formed in step S1-1 and add to In the three-neck flask, stir magnetically under vacuum atmosphere and heat to 120°C, keep for 20 minutes to form a transparent solution; then raise the temperature to 280°C, keep for 1 hour to form a dark blue solution;

[0071] S1-3. Naturally cool the solution obtained in step S2 to 60°C, then add n-hexane and acetone until flocs appear; c...

Embodiment 2

[0077] The difference between the preparation method of this example and the example is that the amount of tungsten chloride in step S1-2 is 0.05 mmol, and other steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com