Method for preparing magnesium-based lanthanum aluminate thermal barrier coating

A magnesium-based lanthanum aluminate and thermal barrier coating technology, which is applied in the field of materials, can solve the problems of volume increase, difficulty in preparing high-purity magnesium-based lanthanum aluminate ceramic materials, and volume changes of coating materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

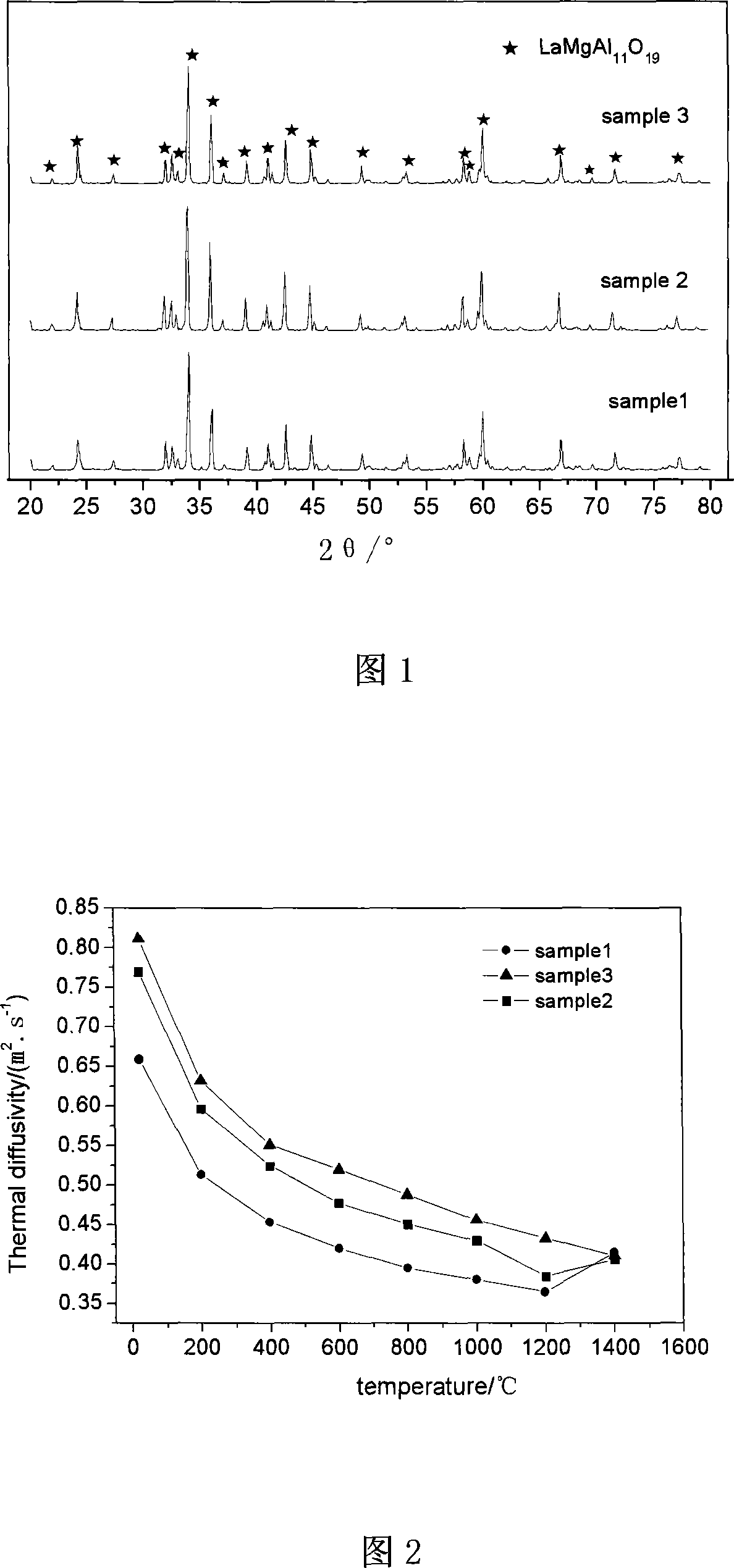

Embodiment 1

[0014] by LaMgAl 11 o 19 Stoichiometric ratios were used for batching. The raw materials used to prepare 1kg of magnesium-based lanthanum aluminate are: lanthanum oxide La 2 o 3 213.34 grams, magnesium oxide MgO52.75 grams, aluminum hydroxide Al(OH) 3 1123.09 grams. Put the weighed various raw materials into a polyurethane ball mill tank, add an appropriate amount of distilled water (or absolute ethanol), and use aluminum oxide balls as grinding bodies for ball milling for 18 hours. The slurry was put into a drying oven and dried at a temperature of 90° C. for 14 h. Compression molding is performed under a pressure of 20 MPa. The molded body was calcined in air at 1550°C for 10 hours to obtain a calcined body. After the calcined body is pulverized, MgO fine powder with a mass fraction of 0.005 is added, put into a polyurethane ball mill tank, and wet milled with distilled water (or absolute ethanol) as a medium for 24 hours to obtain a ceramic slurry. The ceramic slur...

Embodiment 2

[0016] by LaMgAl 11 o 19 The stoichiometric ratio is used for batching, and the raw materials used to prepare 1kg of magnesium-based lanthanum aluminate are: lanthanum oxide La(OH) 3 248.60 g, magnesium hydroxide Mg(OH) 2 76.34 g, aluminum hydroxide Al(OH) 3 1123.09 grams. Put the weighed various raw materials into a polyurethane ball mill tank, add an appropriate amount of distilled water (or absolute ethanol), and use alumina balls as grinding bodies for ball milling for 14 hours. The slurry was put into an oven and dried at 80 °C for 20 h. Compression molding is performed under a pressure of 20 MPa. The molded body was calcined at 1570°C for 8 hours in air to obtain a calcined body. After the calcined body was pulverized, MgO fine powder with a mass fraction of 0.008 was added, put into a polyurethane ball mill tank, and wet-milled with absolute ethanol as a medium for 24 hours to obtain a ceramic slurry. The ceramic slurry was dried at 70°C for 24h, and then an appr...

Embodiment 3

[0018] by LaMgAl 11 o 19 The stoichiometric ratio is used for batching, and the raw materials used to prepare 1kg of magnesium-based lanthanum aluminate are: lanthanum carbonate La 2 (CO 3 ) 3 .8H 2 O393.96g, magnesium oxide MgO52.75g, gamma-alumina gamma-Al 2 o 3 734.02 grams. Put the weighed various raw materials into a polyurethane ball mill tank, add an appropriate amount of distilled water (or absolute ethanol), and use alumina balls as grinding bodies for ball milling for 22 hours. Put the slurry into an oven and dry at 90°C for 20h. Compression molding is performed under a pressure of 20 MPa. The molded body is pre-fired at 1550°C for 8 hours, and the sintering atmosphere is an oxidizing atmosphere. After the calcined body was pulverized, MgO fine powder with a mass fraction of 0.012 was added, put into a polyurethane ball mill tank, and wet-milled with absolute ethanol as a medium for 24 hours to obtain a ceramic slurry. The ceramic slurry was dried at 80°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com