Method for preparing lanthanum aluminate/lanthanum chromate by spraying pyrolysis

A technology of spray pyrolysis and lanthanum aluminate, which is applied in the field of materials to achieve the effect of avoiding high reaction temperature, reducing reaction temperature and time, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Dissolve lanthanum chloride and aluminum chloride in water to make a solution, the concentration of lanthanum chloride in the solution is 350g / L, and the molar ratio of lanthanum to aluminum in the solution is 1:1;

[0062] Using air as the carrier gas, the solution is sprayed into the roasting furnace for spray pyrolysis through a compressor spray. The air flow rate during the spraying process is 5 L / h, and the flow ratio of air to solution is 50:1; The temperature is 500℃ and the time is 60s to obtain the torrefaction; the lanthanum oxychloride and aluminum oxide in the torrefaction are in the form of microcrystalline solid solution; the material after spray pyrolysis enters the cyclone separation device, and the separated solid is the torrefaction Slag and gas enter the tail gas absorption tower;

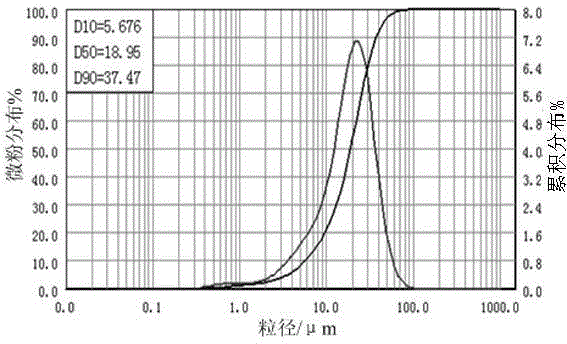

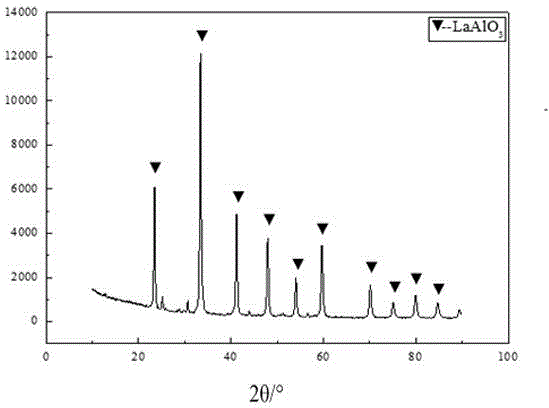

[0063] The slag is calcined at 900℃ for 1.5h to obtain lanthanum aluminate with a particle size of 0.2~100μm, a median diameter of 22.77μm, and LaAlO in weight percentage 3 99...

Embodiment 2

[0066] The method is the same as in Example 1, the difference is:

[0067] (1) The concentration of lanthanum chloride in the solution is 10g / L;

[0068] (2) During the blowing process, the air flow rate is 8000 L / h, and the flow ratio of air to solution is 70:1; the temperature of the roaster is 1700°C, and the time is 1s;

[0069] (3) The slag is calcined at 800℃ for 2h to obtain lanthanum aluminate with a particle size of 0.2-100μm, a median diameter of 18.45μm, and LaAlO in weight percentage 3 99.22%, the rest is LaOCl and Al 2 O 3 Impurities

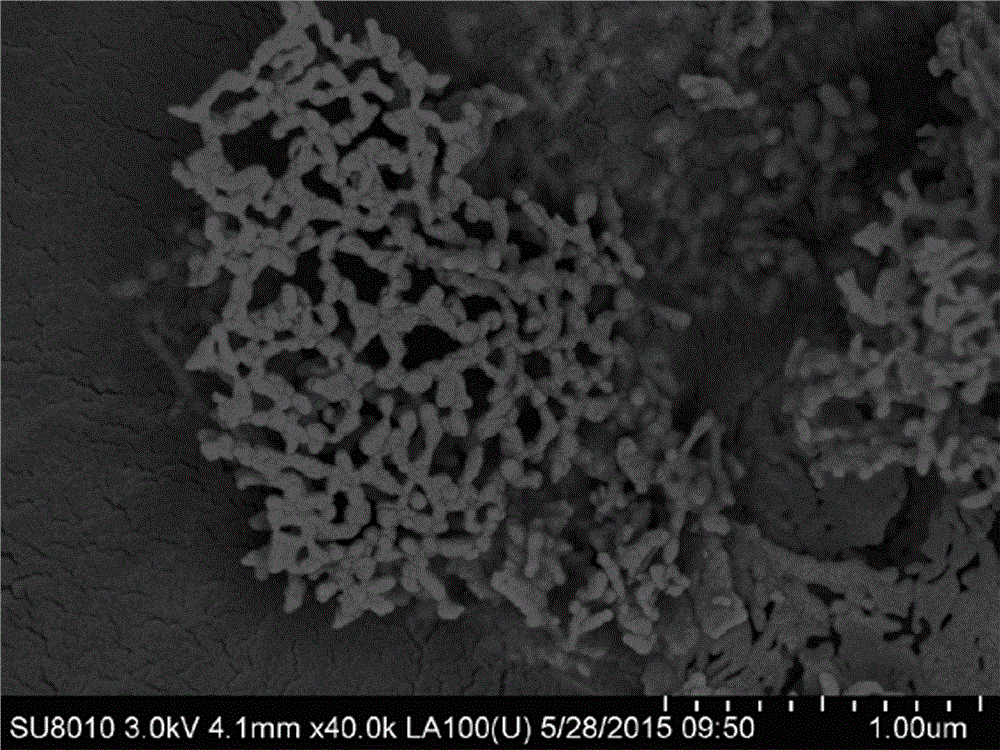

[0070] Scanning electron microscopy results such as Figure 4 As shown, the XRD diffraction results are as Figure 5 As shown, the particle size analysis results are as Image 6 Shown.

Embodiment 3

[0072] The method is the same as in Example 1, the difference is:

[0073] (1) The concentration of lanthanum chloride in the solution is 100g / L;

[0074] (2) During the blowing process, the air flow rate is 800L / h, and the flow ratio of air to solution is 40:1; the temperature of the roaster is 800℃, and the time is 35s;

[0075] (3) The slag is calcined at 850°C for 2.5 hours to obtain lanthanum aluminate with a particle size of 0.2-100μm, a median diameter of 10.09μm, and LaAlO in weight percentage 3 99.50%;

[0076] Scanning electron microscopy results such as Figure 7 As shown, the XRD diffraction results are as Figure 8 As shown, the particle size analysis results are as Picture 9 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com