Second-phase nanoparticle doped YBCO (yttrium barium copper oxide) film and preparation method thereof

A nanoparticle and film technology, which is applied in the field of second-phase nanoparticle-doped YBCO film and its preparation, can solve the problem that the second equality cannot be guaranteed, and achieve the effects of improved Jc performance, low cost, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

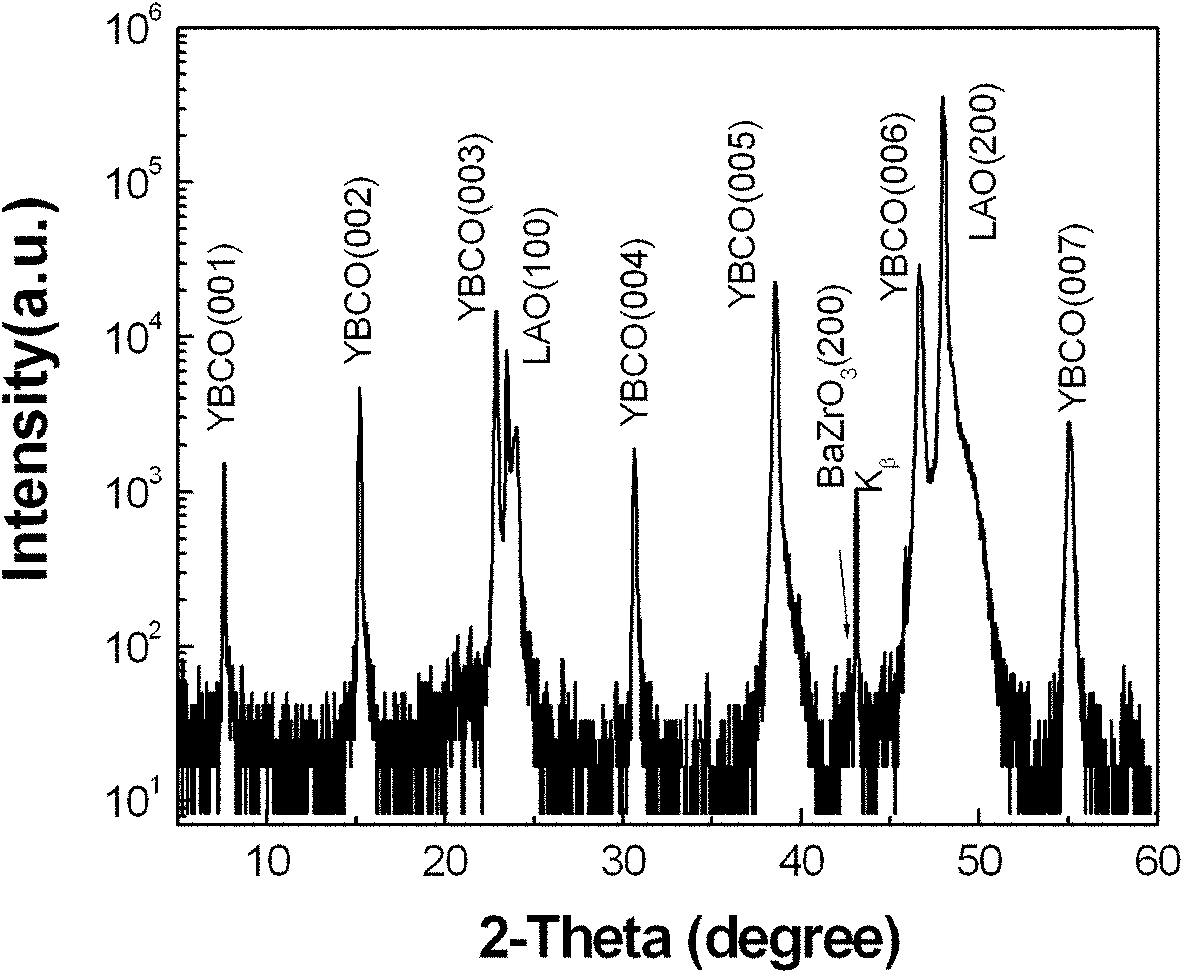

Examples

Embodiment 1

[0027] (1) Preparation of the second phase nanoparticle-doped YBCO precursor:

[0028] a. Dissolve yttrium trifluoroacetate, barium trifluoroacetate and copper trifluoroacetate in methanol according to the atomic ratio of Y: Ba: Cu = 1: 2: 3, then carry out vacuum distillation to remove impurity water, and determine the solution with methanol Obtain the YBCO precursor solution; The total concentration of yttrium, barium and copper metal ions in the YBCO precursor solution is 1mol / L;

[0029] b. The aqueous solution of soluble salt is added in the microemulsion phase, forms the water-in-oil soluble salt microemulsion system by the mode of magnetic stirring or ultrasonic dispersion; Described soluble salt is barium nitrate and zirconium nitrate by Ba:Zr=1: The atomic ratio of 1 is mixed, and the total concentration of metal ions in the aqueous solution of soluble salt is 0.1mol / L; the microemulsion phase is formed by mixing alkane, alcohol and surfactant in a volume ratio of 15:...

Embodiment 2

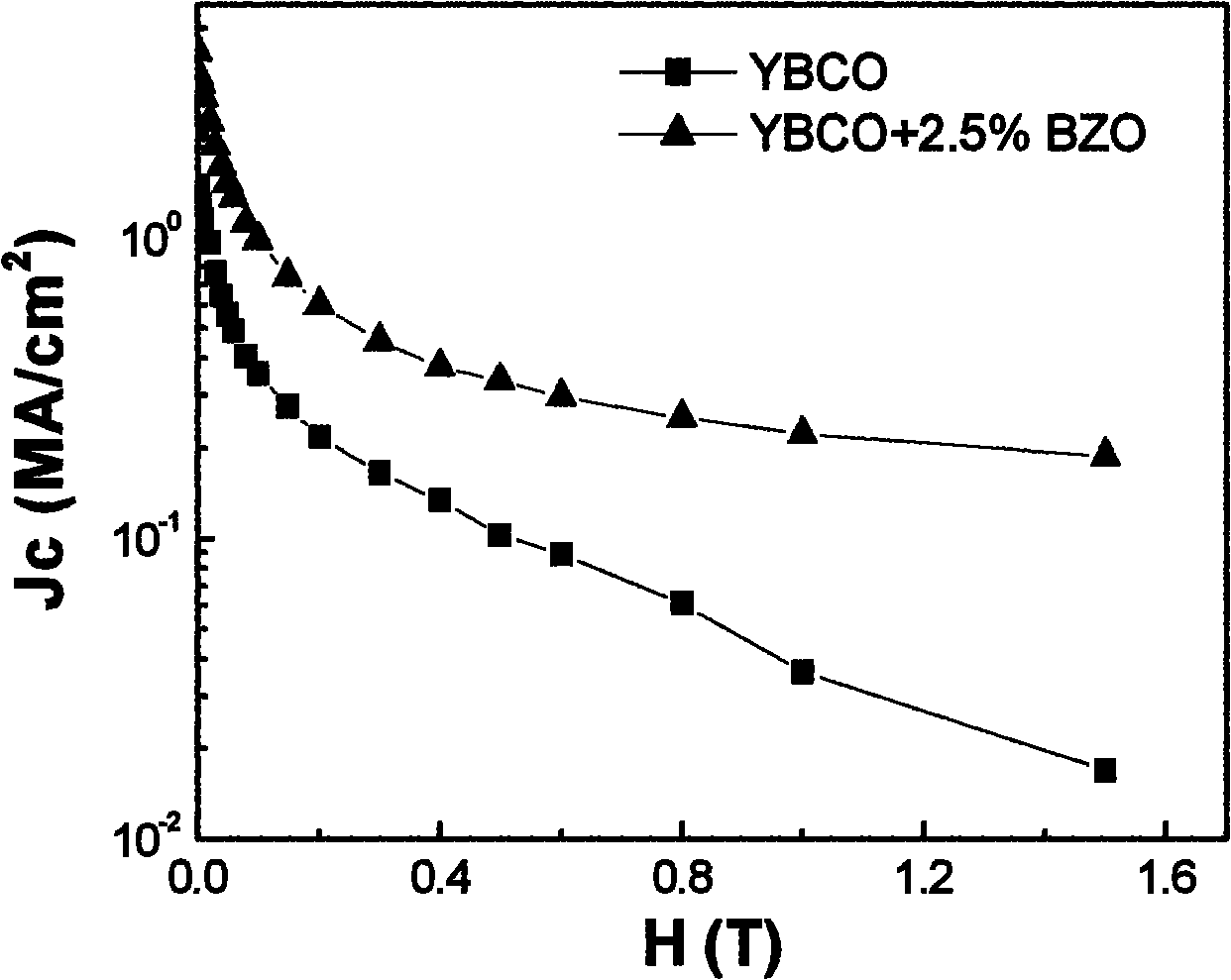

[0040] The preparation method of this embodiment is the same as that of Example 1, except that the soluble salt is mixed with barium nitrate and hafnium nitrate according to the atomic ratio of Ba:Hf=1:1, or barium nitrate, copper nitrate and nitrate Yttrium is mixed according to the atomic ratio of Ba: Cu: Y=1:1:2; the alkane is n-heptane, the alcohol is isoamyl alcohol; the precipitating agent is sodium hydroxide; the second phase nanoparticles for BaHfO 3 or Y 2 BaCuO 5 .

[0041] In this example, by precisely controlling the separate phase formation of the second-phase particles, and at the same time promoting the uniform dispersion of the second phase in the superconducting phase matrix, the second-phase nanoparticle-doped YBCO film prepared compared with the pure YBCO film has a better performance under 77K zero field Jc exceeds 3MA / cm 2 , the Jc performance is significantly improved under the magnetic field.

Embodiment 3

[0043] (1) Preparation of the second phase nanoparticle-doped YBCO precursor:

[0044] a. Dissolve yttrium trifluoroacetate, barium trifluoroacetate and copper trifluoroacetate in methanol according to the atomic ratio of Y: Ba: Cu = 1: 2: 3, then carry out vacuum distillation to remove impurity water, and determine the solution with methanol Obtain the YBCO precursor solution; The total concentration of yttrium, barium and copper metal ions in the YBCO precursor solution is 1.5mol / L;

[0045] b. the aqueous solution of soluble salt is added in the microemulsion phase, forms the water-in-oil soluble salt microemulsion system by the mode of magnetic stirring or ultrasonic dispersion; Described soluble salt is barium nitrate and hafnium nitrate by Ba:Hf=1: The atomic ratio of 1 is mixed; the total concentration of metal ions in the aqueous solution of the soluble salt is 0.5mol / L; the microemulsion phase is mixed by alkane, alcohol and surfactant in a volume ratio of 10:3:1; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com