High-emissivity infrared energy-saving material preparation method

A high-emissivity, energy-saving material technology, applied in the field of preparation of high-emissivity infrared energy-saving materials, can solve the problems of long-term stable service, low infrared emissivity, etc., to achieve industrial production, simple preparation process, and huge application potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Mix and grind lanthanum hydroxide, aluminum oxide, calcium carbonate, and chromium oxide in a molar ratio of 1:1:0.1:0.25, and calcinate the ground mixed raw material powder in an air atmosphere at 1600°C for 360 minutes to cause high-temperature solidification. In contrast, the powder of the high-emissivity infrared energy-saving material is finally prepared. The infrared emissivity of the high-emissivity infrared energy-saving material is 0.95 and the average particle size is 12 μm.

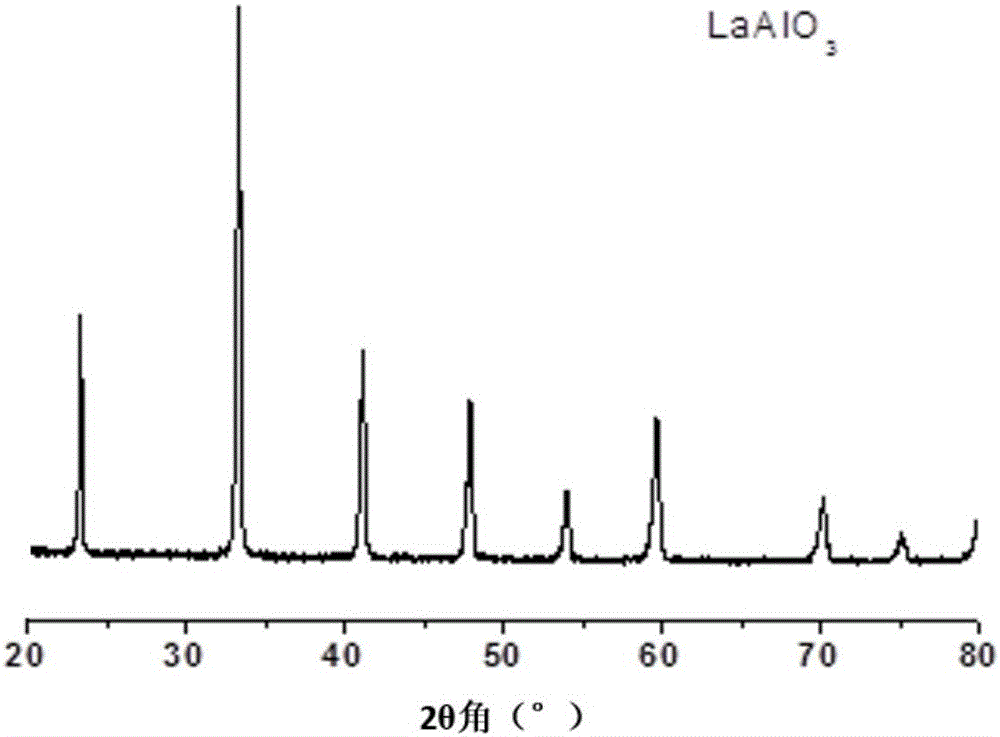

[0049] From figure 1 It can be seen that the phase of the high-emissivity infrared energy-saving material in this embodiment is lanthanum aluminate (LaAlO) with a perovskite structure. 3 ); no other impurity phases were observed, indicating that calcium, chromium and other components have been solid-dissolved into the lattice of lanthanum aluminate, forming a calcium- and chromium-doped lanthanum aluminate-based ceramic material.

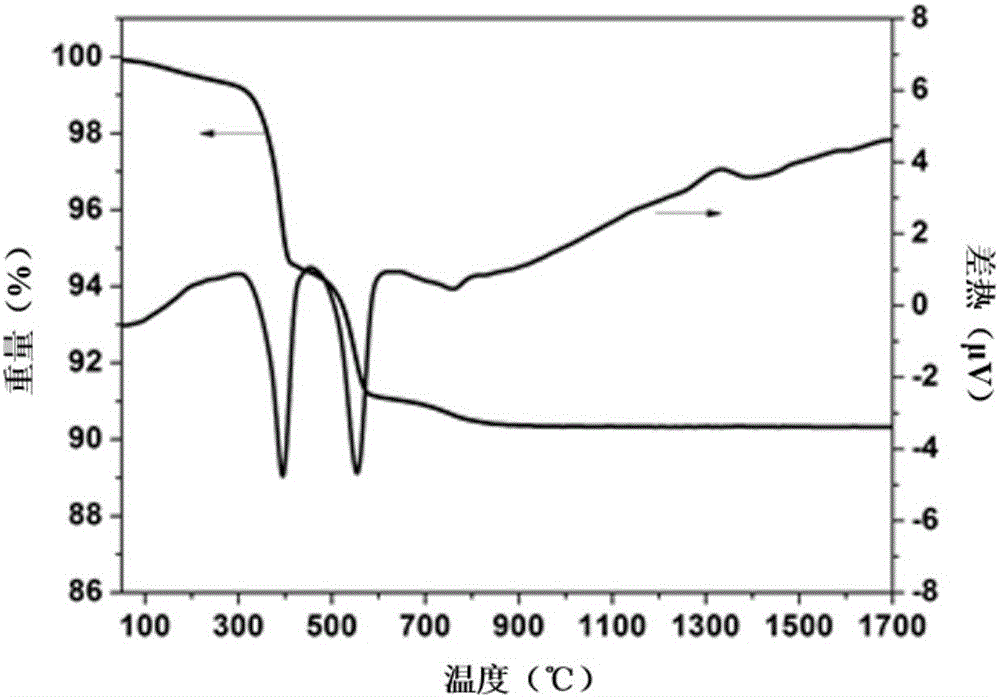

[0050] From figure 2 It can be seen that the synthesi...

Embodiment 2

[0054] Mix and grind lanthanum oxide, aluminum oxide, calcium oxide, and chromium oxide in a molar ratio of 1:1:0.01:0.02, and calcinate the ground mixed raw material powder in an air atmosphere at 1200°C for 300 minutes to generate a high-temperature solid phase reaction, and finally prepare the powder of the high-emissivity infrared energy-saving material, the infrared emissivity of the high-emissivity infrared energy-saving material is 0.80, and the average particle size is 3 μm.

Embodiment 3

[0056] Mix and grind lanthanum oxide, aluminum hydroxide, calcium carbonate, and iron oxide in a molar ratio of 1:1:0.25:0.5, and calcinate the ground mixed raw material powder in an air atmosphere at 1400°C for 300 minutes to cause high-temperature solidification. On the contrary, the powder of the high-emissivity infrared energy-saving material is finally prepared. The infrared emissivity of the high-emissivity infrared energy-saving material is 0.92 and the average particle size is 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com