Growing method of Y<1-x>RE<x>BCO superconducting layer of coated conductor through magnetron sputtering method

A magnetron sputtering and coating conductor technology, which is applied in the usage of superconductor elements, coating, sputtering plating, etc., can solve the problems of critical current density and critical current reduction, reduce production costs, and process parameters are easy to control , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

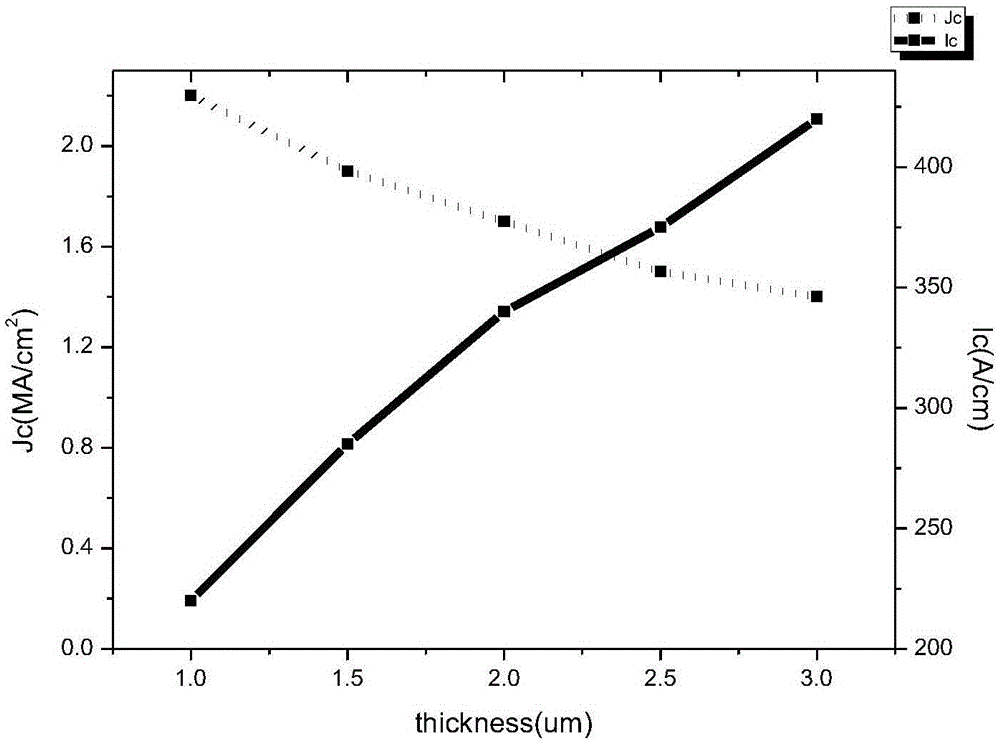

example 1

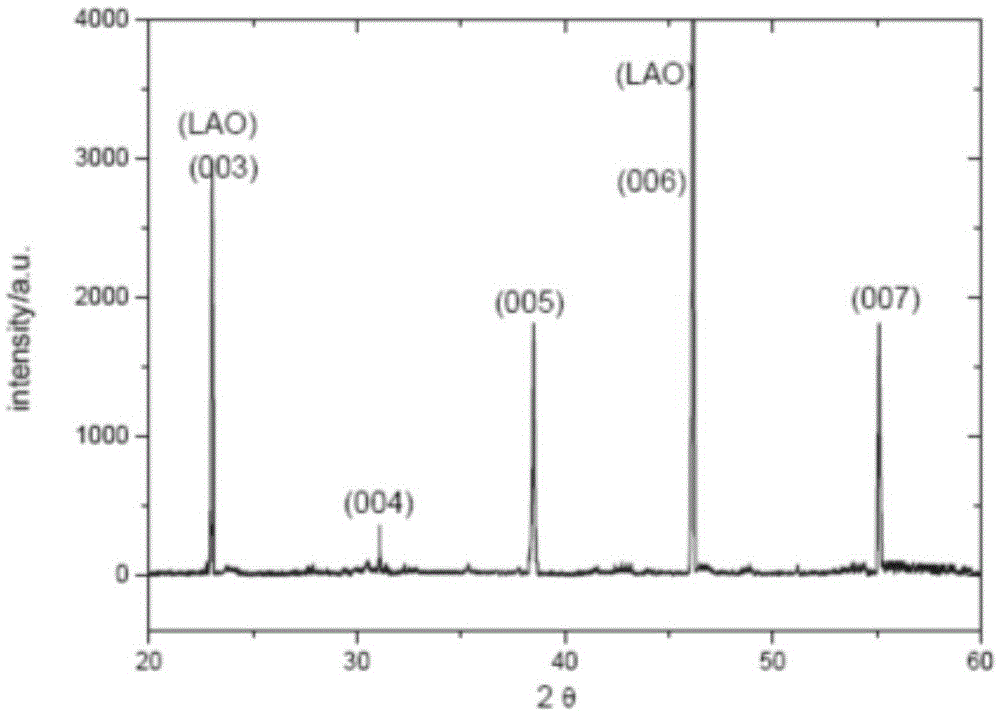

[0020] This embodiment is to prepare a Y with a thickness of 1 μm on a lanthanum aluminate (LAO) substrate. 1-x RE x BCO superconducting layer. The conventional magnetron sputtering deposition process is adopted and carried out in a magnetron sputtering equipment. The specific process is as follows:

[0021] (1) The four metal oxide powders of yttrium oxide, gadolinium oxide, barium oxide, and copper oxide are mixed together according to the molar ratio of metal cations: Y:Gd:Ba:Cu=0.9:0.1:2:3 and used for spherical grinding machine grinding for 5 hours;

[0022] (2) The powder is compressed and molded by dry pressing molding technology, the size of the abrasive tool used is 5cm in diameter, and the molding pressure is 8-14kg / cm 2 ;

[0023] (3) Put the pressed block sample into the furnace, raise the temperature to 850-900°C at a rate of 10°C / min, and keep this temperature for 24 hours, and then raise it to 1050-1100°C at a rate of 10°C / min Keep it for 1 hour, then cool...

example 2

[0028] This embodiment is to prepare a Y with a thickness of 2 μm on a lanthanum aluminate (LAO) substrate. 1-x RE x BCO superconducting layer. The conventional magnetron sputtering deposition process is adopted and carried out in a magnetron sputtering equipment. The specific process is as follows:

[0029] (1) The four metal oxide powders of yttrium oxide, gadolinium oxide, barium oxide, and copper oxide are mixed together according to the molar ratio of metal cations: Y:Gd:Ba:Cu=0.7:0.3:2:3 and used for spherical grinding machine grinding for 7 hours;

[0030] (2), repeat step (2) among the embodiment 1;

[0031] (3), repeat step (3) among the embodiment 1;

[0032] (4), repeat step (4) in embodiment 1;

[0033] (5) Vacuumize the magnetron sputtering chamber to a degree of vacuum less than or equal to 5×10 -4 Pa, heat the metal substrate to 600°C-700°C, fill it with argon and oxygen after 20-30 minutes until the chamber pressure is stable at 30-60Pa, the ratio of oxy...

example 3

[0036] This embodiment is to prepare a Y with a thickness of 3 μm on a lanthanum aluminate (LAO) substrate. 1-x RE x BCO superconducting layer. The conventional magnetron sputtering deposition process is adopted and carried out in a magnetron sputtering equipment. The specific process is as follows:

[0037] (1) The four metal oxide powders of yttrium oxide, gadolinium oxide, barium oxide and copper oxide are mixed together according to the molar ratio of metal cations: Y:Gd:Ba:Cu=0.4:0.6:2:3 and used for spherical grinding Machine grinding for 9 hours;

[0038] (2), repeat step (2) among the embodiment 1;

[0039] (3), repeat step (3) among the embodiment 1;

[0040] (4), repeat step (4) in embodiment 1;

[0041] (5) Vacuumize the magnetron sputtering chamber to a degree of vacuum less than or equal to 5×10 -4 Pa, heat the metal substrate to 600°C-700°C, fill it with argon and oxygen after 20-30 minutes until the chamber pressure is stable at 30-60Pa, the ratio of oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com