Gd-Sm doped YBCO superconducting layer and preparation method thereof

A technology of yttrium barium copper oxide and superconducting layer, applied in the field of superconducting, to achieve the effect of overcoming the thickness effect, precise composition control and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

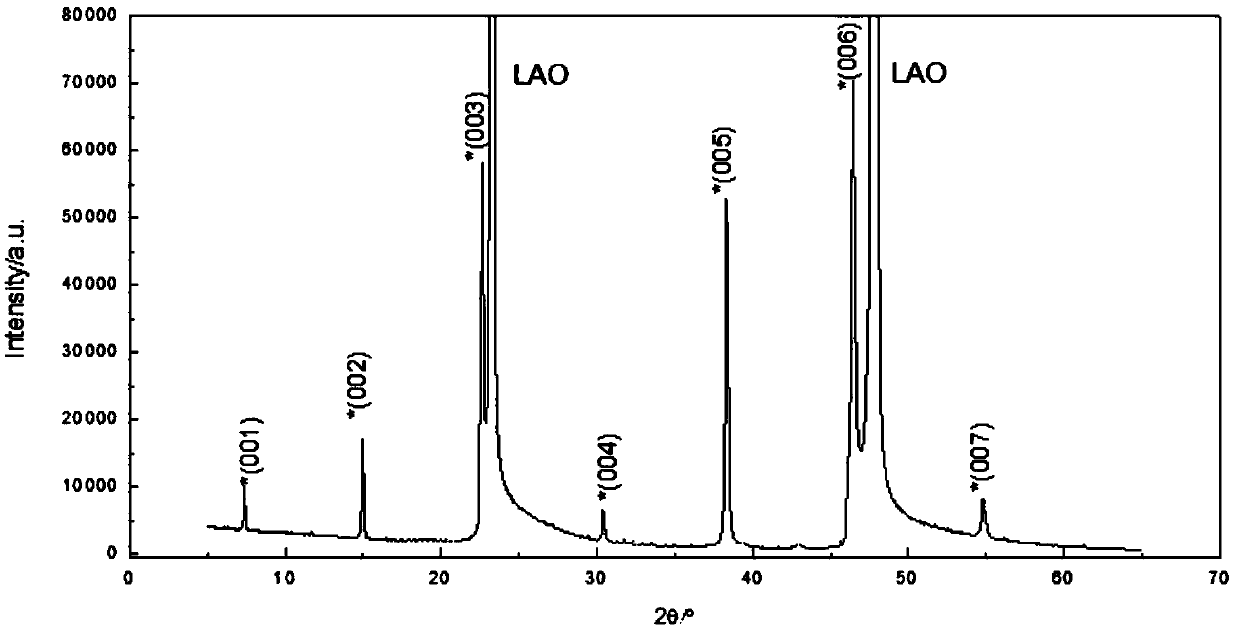

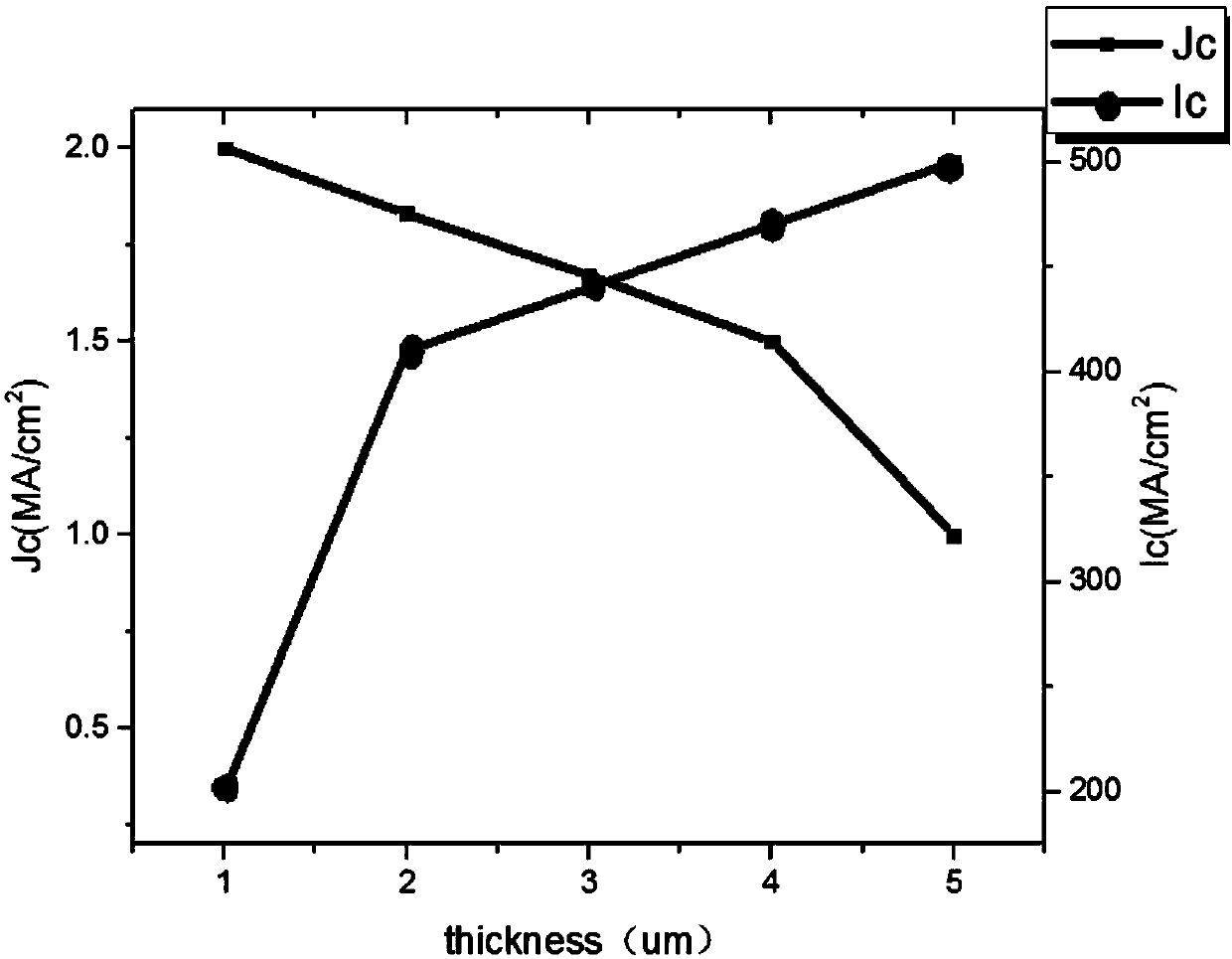

[0020] In this embodiment, a ReBCO superconducting layer with a thickness of 1 μm is prepared on an LAO substrate. The conventional metal-organic solution deposition process is carried out by dipping puller equipment. The specific process is as follows:

[0021] (1) Dissolve the five acetates of yttrium acetate, gadolinium acetate, samarium acetate, barium acetate, and copper acetate in the deionized ratio of Y:Gd:Sm:Ba:Cu=0.8:0.1:0.1:2:3.15 water to obtain solution A;

[0022] (2) Add an appropriate amount of propionic acid to A, and stir evenly to make it fully react, and then repeatedly distill the solution under vacuum at 70°C to obtain solution B;

[0023] (3) Add methanol to solution B, adjust the concentration of the solution to 1.5mol / L, and add PVB as a thickener, the mass ratio of the thickener to the solution is 1:20, stir evenly, and obtain a blue-black transparent colloidal precursor liquid;

[0024] (4), using dipping and pulling machine for coating, the dipp...

Embodiment 2

[0028] In this embodiment, a ReBCO superconducting layer with a thickness of 2 μm is prepared on an LAO substrate. The conventional metal-organic solution deposition process is carried out by dipping puller equipment. The specific process is as follows:

[0029] The preparation method of the present embodiment is different from embodiment 1 except that steps (1) and (4) are different, and all the other repeat the steps in embodiment 1, and concrete process is as follows:

[0030] (1) Dissolve the five acetates of yttrium acetate, gadolinium acetate, samarium acetate, barium acetate, and copper acetate in the deionized ratio of Y:Gd:Sm:Ba:Cu=0.7:0.2:0.1:2:3.15 water to obtain solution A;

[0031] (2), repeat step (2) among the embodiment 1;

[0032] (3), add methanol to solution B, adjust the solution concentration to 1.5mol / L, and add PVB as a thickener, the mass ratio of the thickener to the solution is 1:18, stir evenly, and obtain a blue-black transparent colloidal precu...

Embodiment 3

[0037] In this embodiment, a ReBCO superconducting layer with a thickness of 3 μm is prepared on an LAO substrate. The conventional metal-organic solution deposition process is carried out by dipping puller equipment. The specific process is as follows:

[0038] The preparation method of the present embodiment is different from embodiment 1 except that steps (1) and (4) are different, and all the other repeat the steps in embodiment 1, and concrete process is as follows:

[0039] (1) Dissolve the five acetates of yttrium acetate, gadolinium acetate, samarium acetate, barium acetate, and copper acetate in the deionized ratio of Y:Gd:Sm:Ba:Cu=0.6:0.3:0.1:2:3.15 water to obtain solution A;

[0040] (2), repeat step (2) among the embodiment 1;

[0041] (3), add methanol to solution B, adjust the solution concentration to 1.5mol / L, and add PVB as a thickener, the mass ratio of the thickener to the solution is 1:16, stir evenly, and obtain a blue-black transparent colloidal precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com