Growth method of coated conductor DyBCO superconductive layer and DyBCO-coated conductor

A technology of coated conductors and growth methods, applied in the usage of superconductor elements, coatings, superconducting devices, etc., can solve the problems of limited thickness of YBCO film, reduced superconducting current carrying capacity, and difficulty in making superconducting films, etc. , to achieve the effect of easy control of process parameters, increase of superconducting current-carrying capacity, and overcoming thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

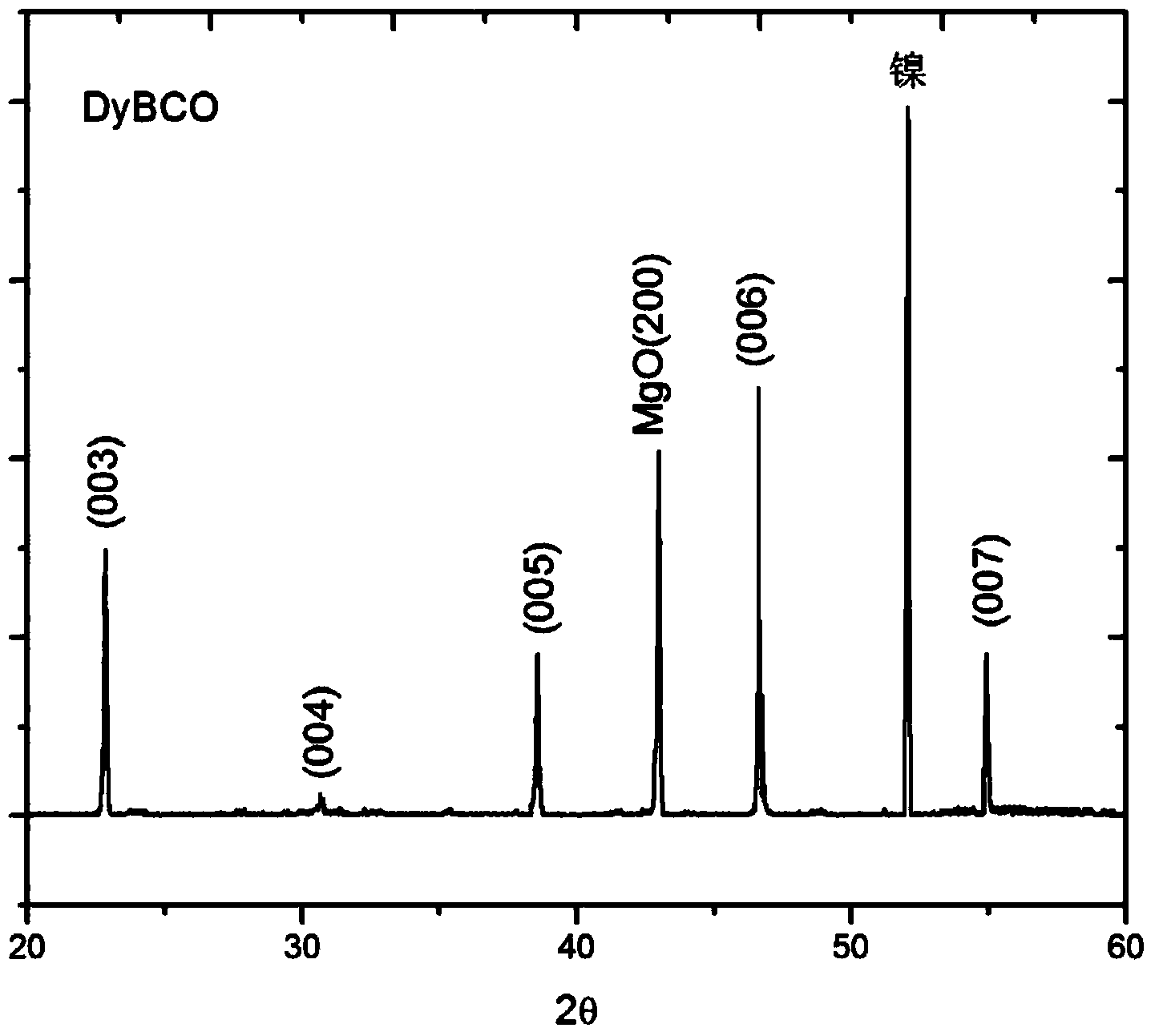

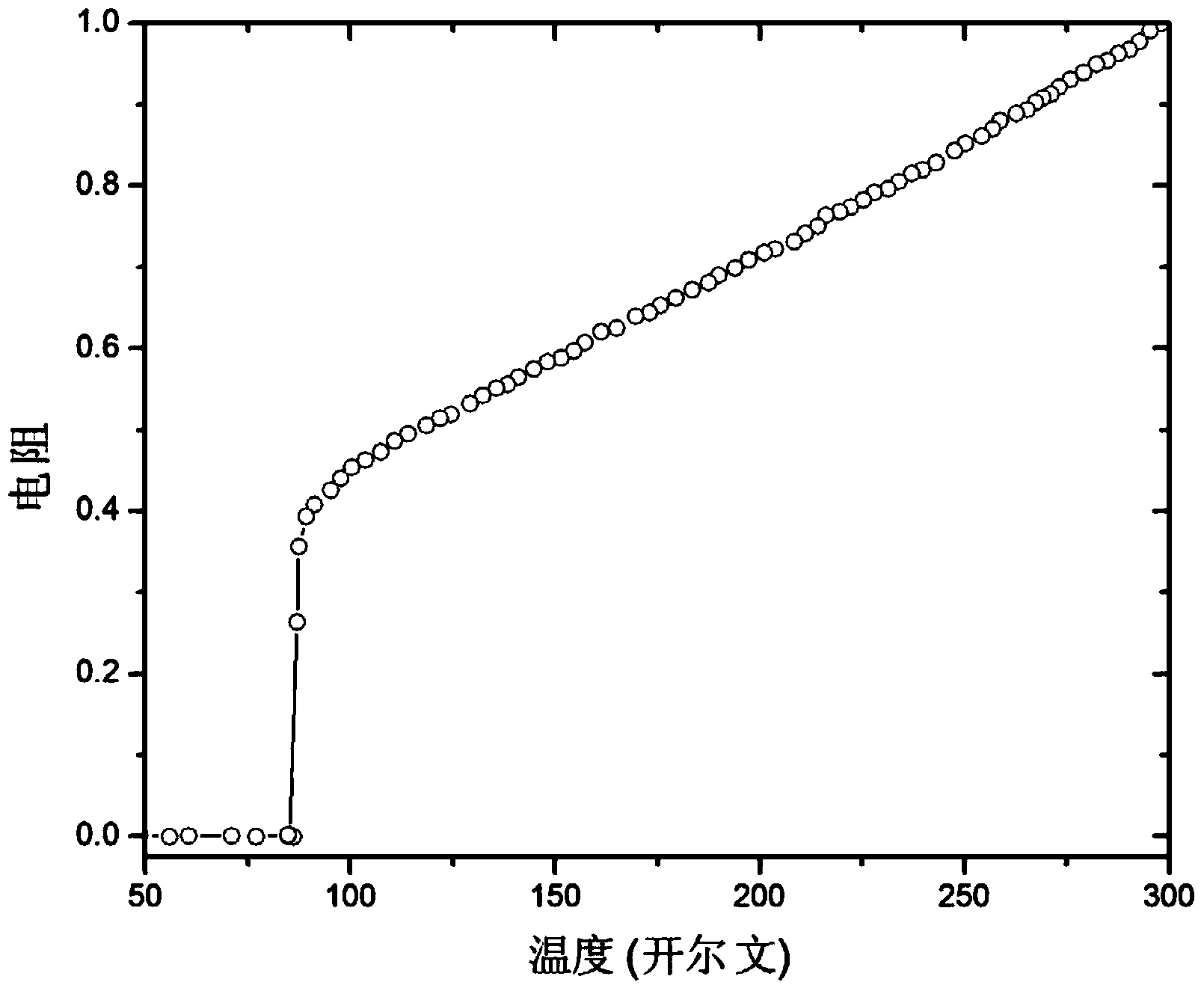

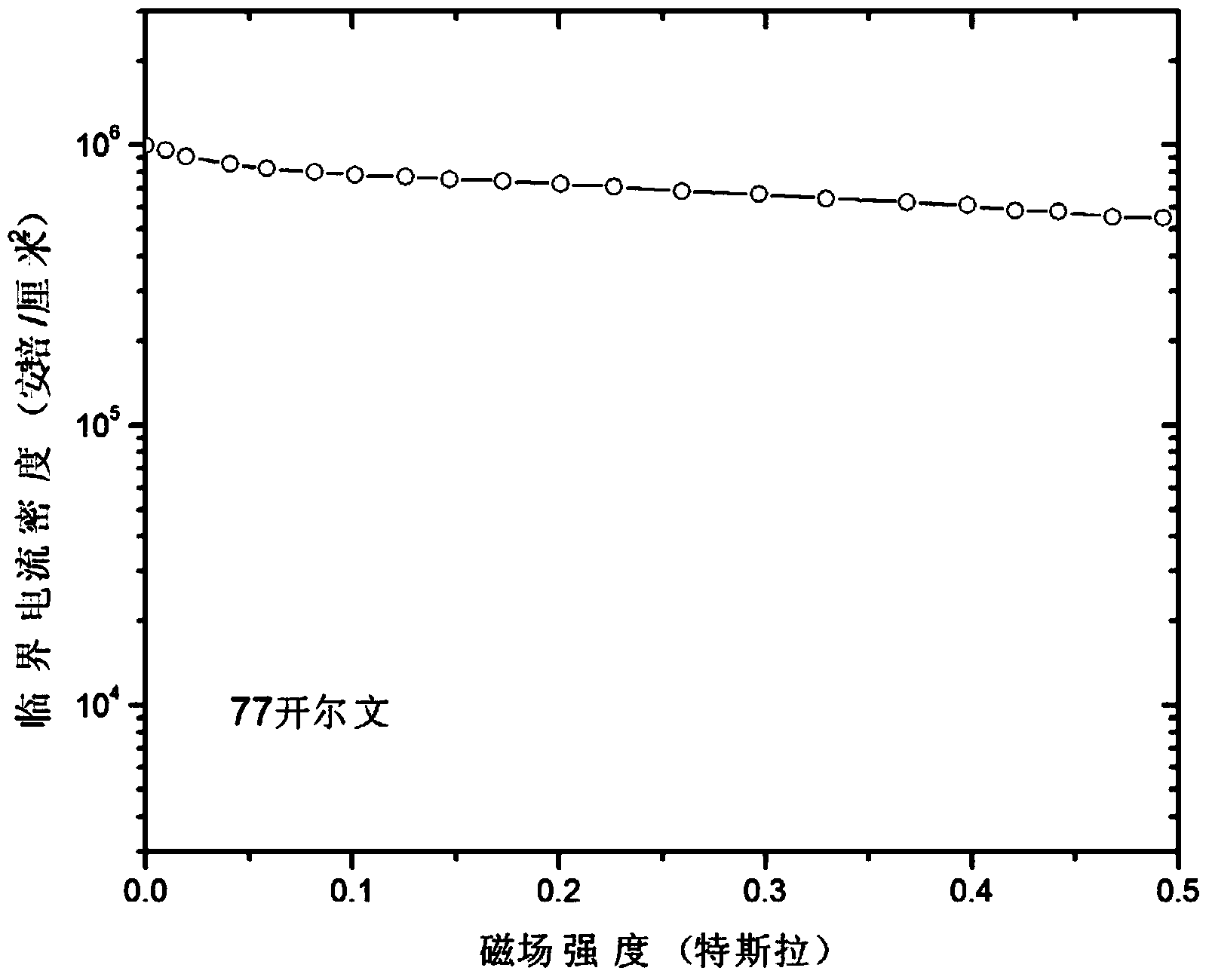

[0027] In this embodiment, a DyBCO superconducting layer with a thickness of 1 μm is prepared on a metal substrate with a cubic textured oxide isolation layer. The conventional magnetron sputtering deposition process is adopted and carried out in a magnetron sputtering equipment. The specific process is as follows:

[0028] (1) Install the DyBCO target on the target holder in the reaction chamber;

[0029] (2) Use 99.99% acetone, alcohol and deionized water in order to ultrasonically clean the metal substrate with a cubic texture oxide isolation layer, and place the cleaned substrate in the heating device of the magnetron sputtering reaction chamber on standby;

[0030] (3), vacuumize the reaction chamber to 5×10 -4 Pa, heat the metal substrate to 600°C-700°C, fill it with argon and oxygen after 20-30 minutes until the cavity pressure is stable at 30Pa-60pa, and the ratio of oxygen to argon is 1:2-1:3. The DyBCO superconducting layer was deposited by magnetron sputtering, ...

Embodiment 2

[0033] In this embodiment, a DyBCO superconducting layer with a thickness of 3 μm is prepared on a metal substrate with a cubic textured oxide isolation layer. The conventional magnetron sputtering deposition process is adopted and carried out in a magnetron sputtering equipment. The specific process is as follows:

[0034] The preparation method of the present embodiment is different from embodiment 1 except that step (3), all the other repeat the steps in embodiment 1, concrete process is as follows:

[0035] (1), repeat step (1) among the embodiment 1;

[0036] (2), repeat step (2) among the embodiment 1;

[0037] (3), vacuumize the reaction chamber to 5×10 -4 Pa, heat the metal substrate to 600°C-700°C, fill it with argon and oxygen after 20-30 minutes until the cavity pressure is stable at 30Pa-60pa, the ratio of oxygen to argon is 1:2-1:3, using magnetron Sputtering begins to deposit the DyBCO superconducting layer, the sputtering time is 10 hours, and the thickness ...

Embodiment 3

[0040] In this embodiment, a DyBCO superconducting layer with a thickness of 5 μm is prepared on a metal substrate with a cubic textured oxide isolation layer. The conventional magnetron sputtering deposition process is adopted and carried out in a magnetron sputtering equipment. The specific process is as follows:

[0041] The preparation method of the present embodiment is different from embodiment 1 except that step (3), all the other repeat the steps in embodiment 1, concrete process is as follows:

[0042] (1), repeat step (1) among the embodiment 1;

[0043] (2), repeat step (2) among the embodiment 1;

[0044] (3), vacuumize the reaction chamber to 5×10 -4 Pa, heat the metal substrate to 600°C-700°C, fill it with argon and oxygen after 20-30 minutes until the cavity pressure is stable at 30Pa-60pa, the ratio of oxygen to argon is 1:2-1:3, using magnetron Sputtering begins to deposit the DyBCO superconducting layer, the sputtering time is 15 hours, and the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com