Novel low-melting-point lead-free solder

A technology of lead-free solder and low melting point, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc. , Difficulty and other problems, to achieve the effect of excellent thermal shock resistance, low cost, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

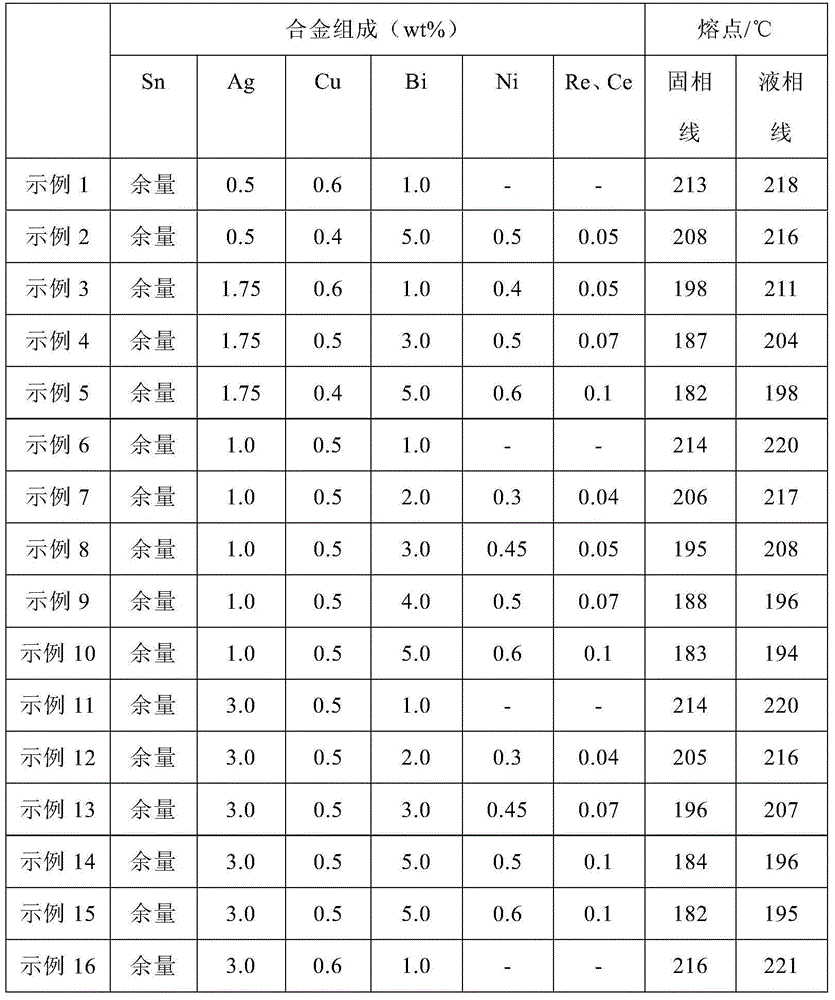

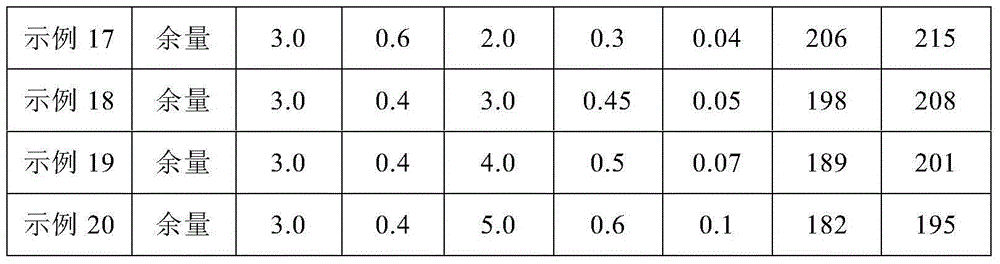

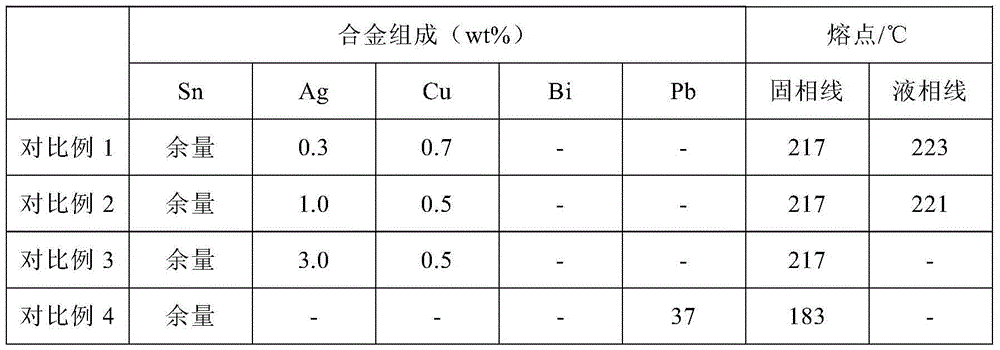

[0018] A new type of low-melting point lead-free solder provided by this specific embodiment, the mass percent of its chemical composition is: 0.3-3.5% Ag, 0.3-0.7% Cu, 0.8-6.0% Bi, 0.1-0.6% Ni , 0.01%-0.15% of rare earth metals, the balance is Sn.

[0019] We found that adding element Bi to Sn-Ag-Cu lead-free solder can lower the melting point of the solder and reduce the surface tension; at the same time, the addition of Bi also slows down the reaction speed of Sn and Cu, making the wettability of the solder worse. better. However, a large amount of Bi used in the alloy has a great influence on the mechanical properties of the alloy, and it is easy to produce tin partiality, which makes the interface layer of the alloy unstable, and eventually leads to poor reliability of solder joints. Therefore, the Bi content in the alloy should not be too high, 0.8-6.0% is a more suitable ratio, and in the preferred technical solution, 1.0-5.0% is a more suitable ratio.

[0020] In add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com