Molybdenum sulfide-coated cobalt-MOF/NF hydrogen evolution material, in-situ synthesis method and application

A technology of in-situ synthesis and hydrogen evolution reaction, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve problems such as hindering large-scale application, high cost and scarcity, and achieve improved hydrogen evolution performance and stability, low raw material cost, The effect of the fast rate of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]

[0033] The above-mentioned hydrogen evolution material is prepared by the following steps of preparation method:

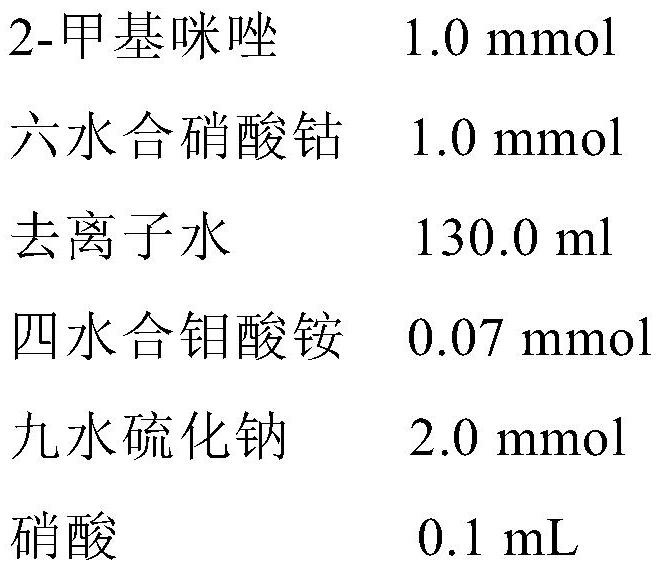

[0034] Dissolve 1mmol of 2-methylimidazole and 1mmol of cobalt nitrate hexahydrate in 30mL and 50mL of deionized water respectively. After mixing, stir in a magnetic stirrer for 30min until there are no solid particles in the solution and the color is purple. Soak 1mm×4mm×1mm nickel foam at room temperature for 10h, rinse the soaked Co-MOF / NF with absolute ethanol and deionized water twice, and dry overnight at 60°C under vacuum; add 0.07mmol molybdic acid tetrahydrate Ammonium and 2mmol sodium sulfide nonahydrate were dissolved in 50mL deionized water, and 0.1mL nitric acid was added dropwise to adjust the pH. Potential electrodeposition, voltage: -0.8V; electrodeposition time: 1200s. Finally got MoS 2 @Co-MOF / NF hydrogen evolution material.

Embodiment 2

[0040]

[0041] The above-mentioned hydrogen evolution material is prepared by the following steps of preparation method:

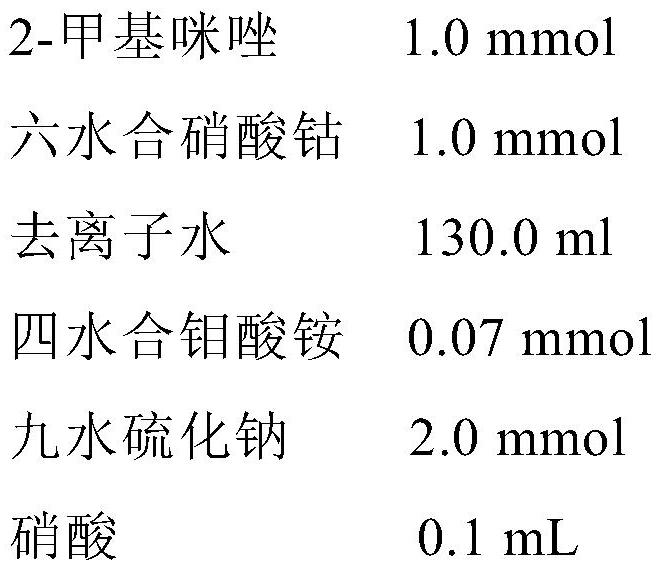

[0042] Dissolve 1mmol of 2-methylimidazole and 1mmol of cobalt nitrate hexahydrate in 30mL and 50mL of deionized water respectively. After mixing, stir in a magnetic stirrer for 30min until there are no solid particles in the solution and the color is purple. Soak 1mm×4mm×1mm nickel foam at room temperature for 10h, rinse the soaked Co-MOF / NF with absolute ethanol and deionized water twice, and dry overnight at 60°C under vacuum; add 0.07mmol molybdic acid tetrahydrate Ammonium and 2mmol sodium sulfide nonahydrate were dissolved in 50mL deionized water, and 0.1mL nitric acid was added dropwise to adjust the pH. Potential electrodeposition, voltage: -0.8V; electrodeposition time: 2400s. Finally got MoS 2 @Co-MOF / NF hydrogen evolution material.

Embodiment 3

[0048]

[0049] The above-mentioned hydrogen evolution material is prepared by the following steps of preparation method:

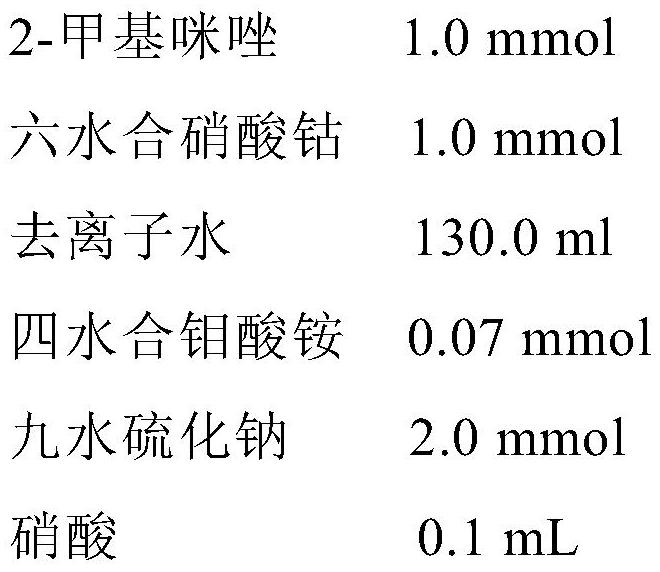

[0050] Dissolve 1mmol of 2-methylimidazole and 1mmol of cobalt nitrate hexahydrate in 30mL and 50mL of deionized water respectively. After mixing, stir in a magnetic stirrer for 30min until there are no solid particles in the solution and the color is purple. Soak 1mm×4mm×1mm nickel foam at room temperature for 10h, rinse the soaked Co-MOF / NF with absolute ethanol and deionized water twice, and dry overnight at 60°C under vacuum; add 0.07mmol molybdic acid tetrahydrate Ammonium and 2mmol sodium sulfide nonahydrate were dissolved in 50mL deionized water, and 0.1mL nitric acid was added dropwise to adjust the pH. Potential electrodeposition, voltage: -0.8V; electrodeposition time: 7200s. Finally got MoS 2 @Co-MOF / NF hydrogen evolution material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com