A nanoporous copper/platinum core-shell structure catalytic electrode and its preparation method

A technology of nanoporous copper and core-shell structure, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, electrodes, etc. Difficulty in transfer and use, etc., to achieve the effect of simple preparation method, controllable size and continuous film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: the preparation of alloy precursor thin film

[0046] The alloy precursor thin film is prepared by magnetron sputtering. The equipment used is the TRP-450 high vacuum three-target magnetron coating system produced by Shenyang Scientific Instruments, Chinese Academy of Sciences. The coating quality is good and the operation is simple; the annealing equipment is Shenyang, Chinese Academy of Sciences. The scientific instrument TRP-450 high vacuum three-target magnetron coating system has its own substrate heating function.

[0047] Concrete preparation steps are as follows:

[0048] (1) The commercial copper foil substrate (with a copper content of more than 96%) was ultrasonically cleaned with acetone for 5 minutes to remove residual organic matter on the surface, and then ultrasonically cleaned with 20-fold concentrated hydrochloric acid for 5 minutes to remove surface oxides. Finally, anhydrous Ethanol removes residual solution ions on the surface and dri...

Embodiment 2

[0053] Embodiment 2: the preparation of nanoporous copper matrix

[0054] Cut the alloy precursor film prepared in Example 1 into a size of 1.0×0.5cm (it can be cut into different quantities according to needs), and put it into the prepared 1mol / L hydrochloric acid solution. The volume of the solution can be measured as needed , you need to pass N before putting in 2 Remove residual oxygen in the solution for 5 minutes, and then corrode in a water bath at 25°C for 12 hours. The obtained sample is cleaned with deionized water to obtain a nanoporous copper matrix.

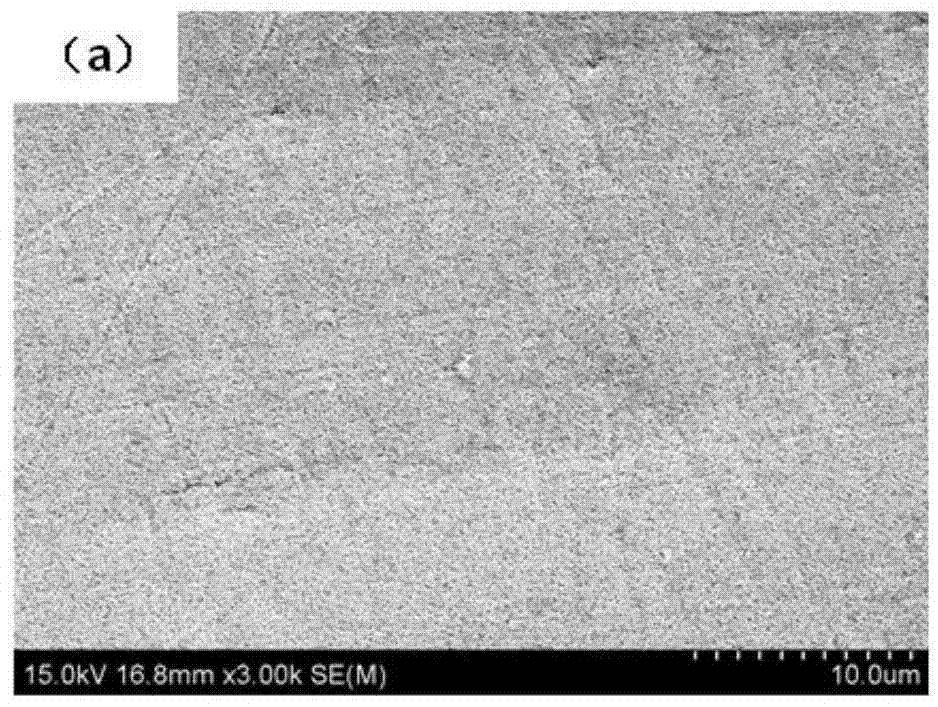

[0055] The SEM image of the nanoporous copper matrix prepared in this embodiment is as follows Figure 4a and Figure 4b As shown, it can be seen from the figure that the diameter of the average nanopore of nanoporous copper is about 220nm, the film thickness of nanoporous copper is about 500nm, and the pore size distribution is uniform and the structure is continuous. decisive role.

Embodiment 3

[0056] Example 3: Preparation of nanoporous copper / platinum core-shell catalyst

[0057] The nanoporous copper matrix prepared in Example 2 is soaked in 0.5g / L of H 2 PtCl 6 In a platinum salt solution composed of 3g / L HCl, the soaking reaction time is 50min; after the reaction is completed, the sample is taken out, washed, and dried to prepare a nanoporous copper / platinum core-shell catalyst.

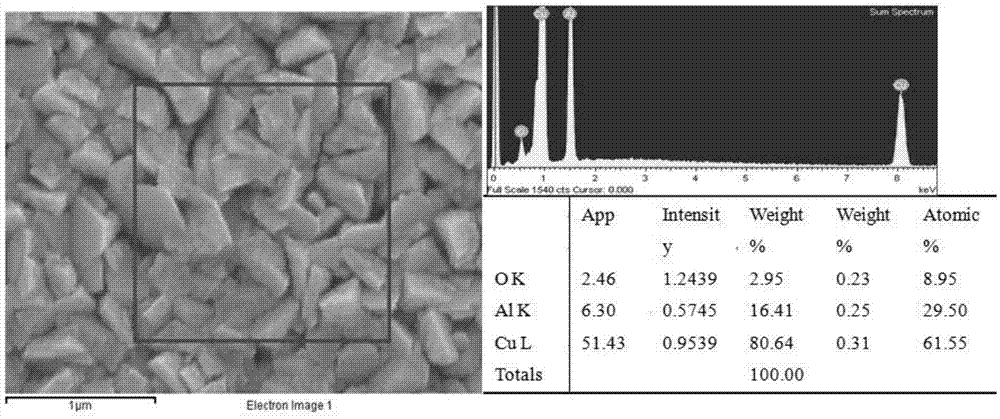

[0058] Material characterization and compositional analysis: the catalyst material prepared in this embodiment observes the microstructure with a scanning electron microscope (SEM), and uses an energy dispersive spectrometer (EDS) attached to the SEM to characterize the presence of platinum nuclei. The results are as follows: Figure 5a , Figure 5b and Figure 6 as shown, Figure 5a -b shows the formed core-shell structure. Compared with the original nanoporous copper structure, it will be found that the original dendrite and strip structure has become a spherical structure. It ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com