Main unit structure of digital control laser cutting machine tool

A CNC laser and cutting machine technology, applied in laser welding equipment, metal processing machinery parts, large fixed members, etc., can solve problems such as poor transmission rigidity, reduced cutting accuracy, asynchronous distortion of gantry beams, etc., to enhance stability and Strength, improve cutting accuracy, reduce the effect of the overall inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

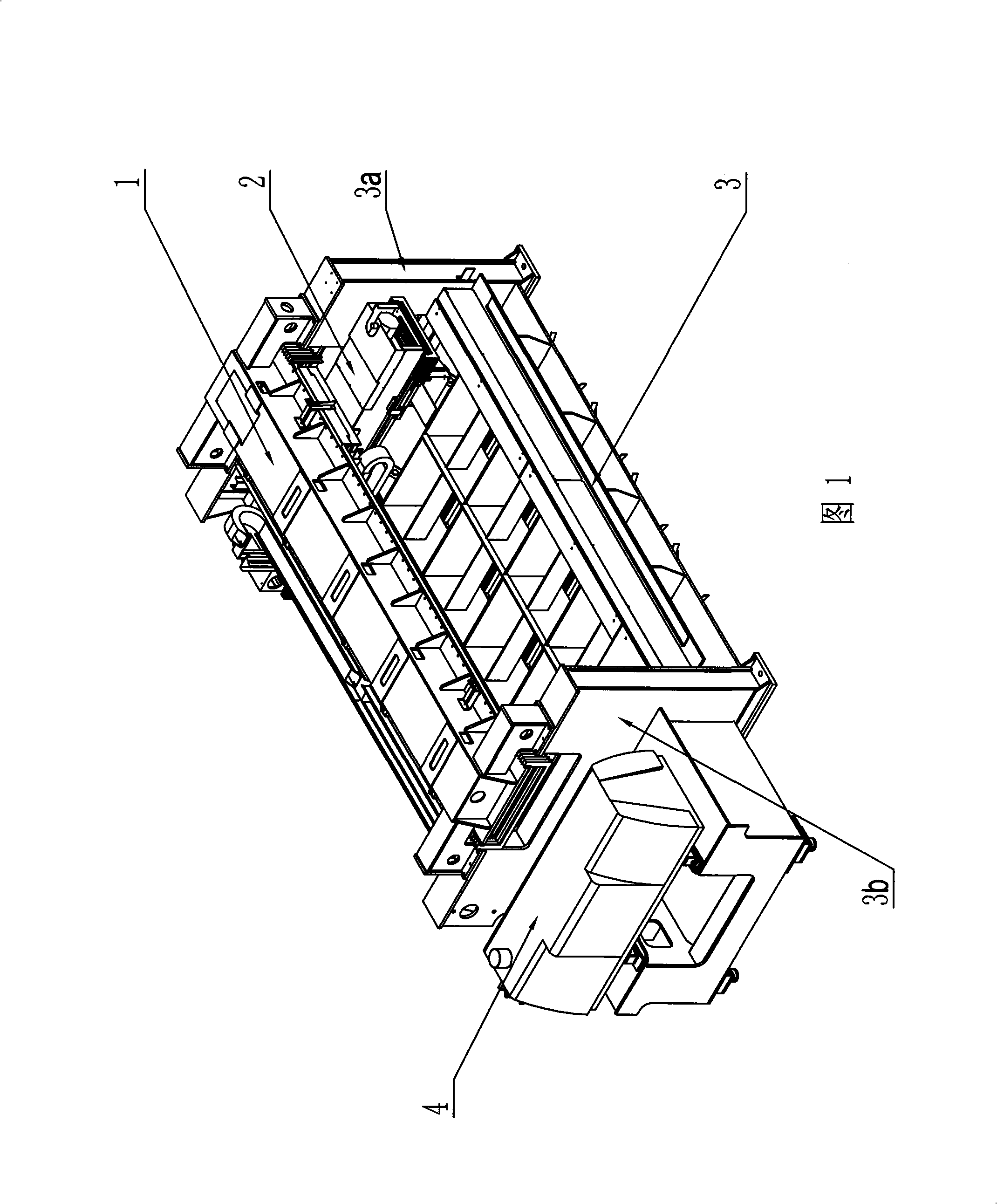

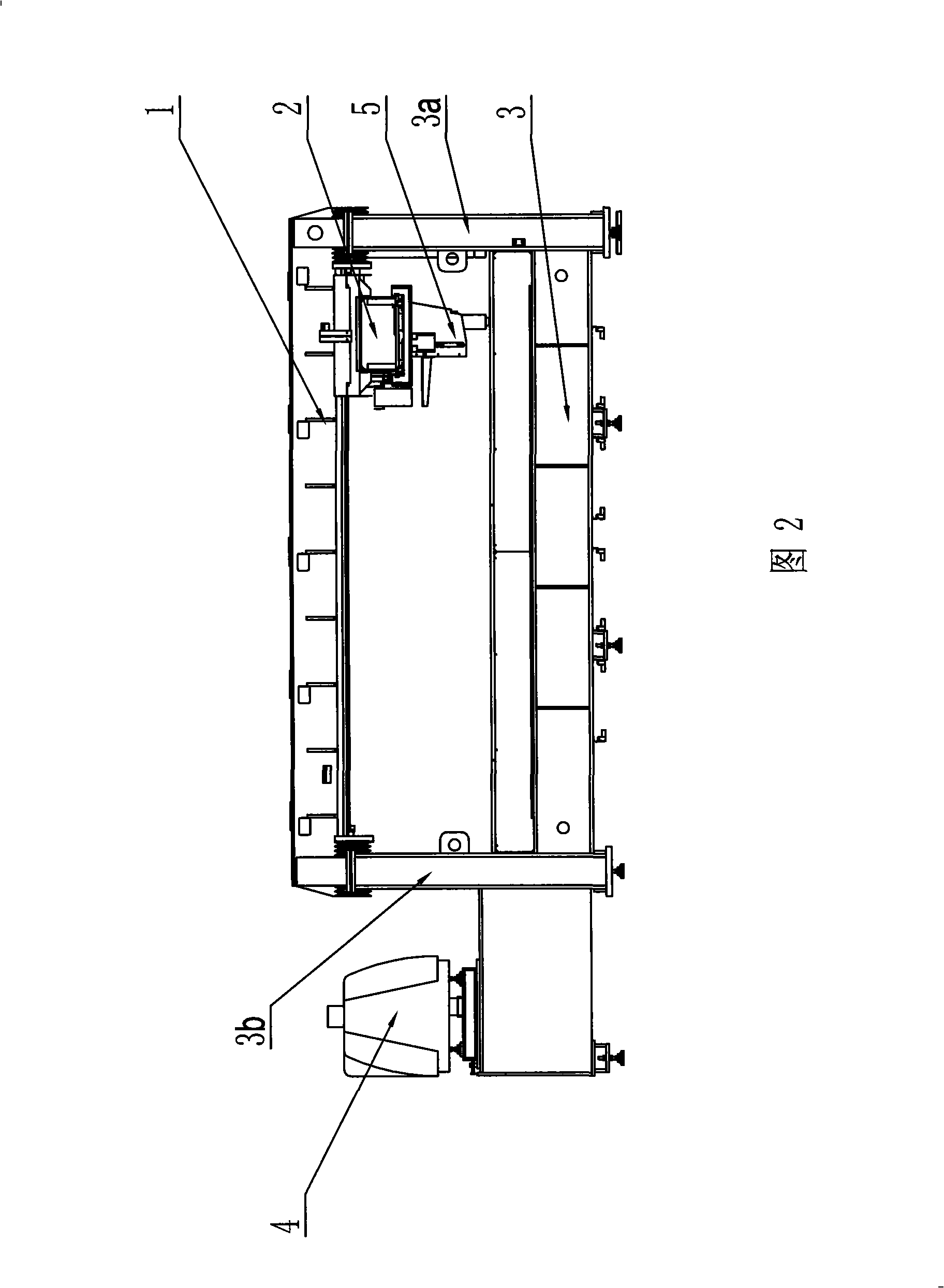

[0014] As shown in Figure 1-2, it is the host structure of the CNC laser cutting machine, including the fuselage 3, the laser 4, the gantry beam 1 and the cutting head 5. It is composed of a plurality of integral steel plates welded, the support frames 3a, 3b are part of the fuselage, and the gantry beam is arranged between the upper sides of the support frames 3a, 3b; the laser 4 is fixedly installed on the support frame 3b at one end, when the laser 4 emits laser light , the laser beam is transmitted to the cutting head 5 to realize cutting. The two ends of the gantry beam 1 are respectively fixedly connected with the corresponding support frames 3a and 3b. 2 and the gantry beam 1 are vertically arranged in space, and the lower side of the moving beam 2 is suspended with a cutting head 5 that can move along the length direction of the moving beam.

[0015] This device fixedly connects the gantry beam 1 with the support frame 3a, 3b, so that the fuselage 3 forms a stable annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com