Thin film flip structure Micro-LED chip transferred by adhesive layer, and preparation method thereof

A thin-film flip-chip and adhesive layer technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of uneven heating of epitaxial wafers, small laser spot area, and local heating, so as to improve light extraction efficiency and improve Photoelectric properties, the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the thin-film flip-chip micro-LED chip with the adhesive layer transferred and the preparation method thereof according to the present invention will be described in detail below with reference to the accompanying drawings.

[0051]

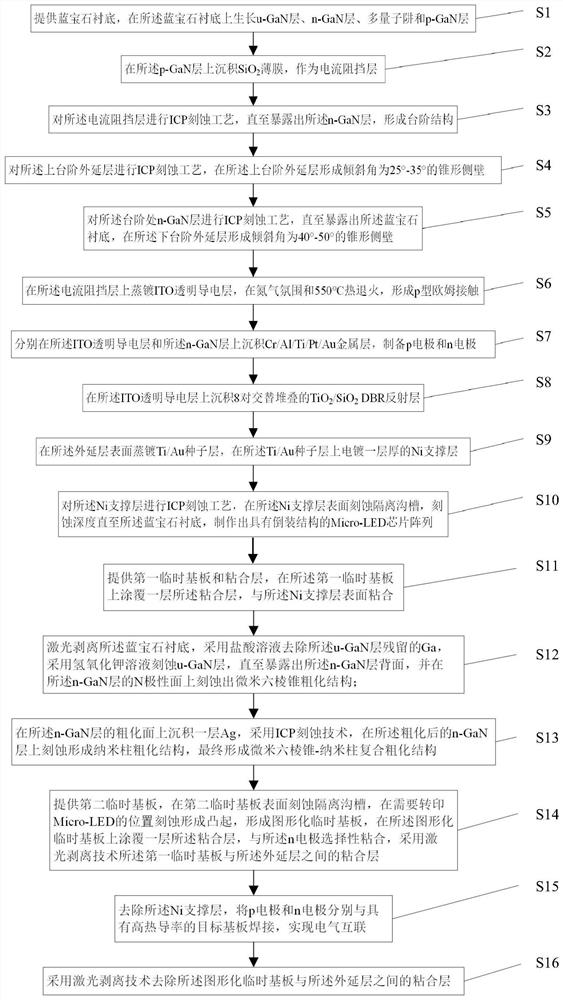

[0052] Such as Figures 1 to 8 As shown, the preparation method of the thin-film flip-chip structure Micro-LED chip with adhesive layer transfer provided in this embodiment includes the following steps:

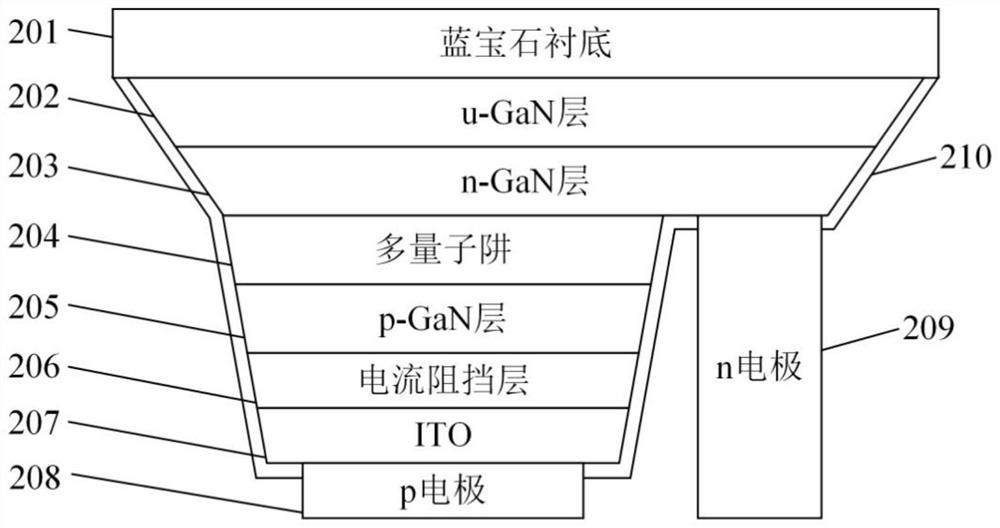

[0053] S1: Provide a sapphire substrate 201, grow an epitaxial layer 200 on the sapphire substrate 201, and the epitaxial layer 200 is an undoped u-GaN layer 202, a Si-doped n-GaN layer 203, and an InGaN / GaN layer from bottom to top. The multiple quantum wells 204 and the Mg-doped p-GaN layer 205; specifically, the epitaxial layer 200 is grown by MOCVD technology, and the light emission wavelength of the epitaxial layer 200 is 450nm.

[0054] S2: Deposit SiO on the p-GaN layer by PECVD technology 2 thin fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com