Stealth cutting LED (light emitting diode) chip and manufacture method thereof

A LED chip and stealth cutting technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problem that invisible cutting lasers cannot penetrate, and achieve the effects of benefiting light output, reducing light absorption, and improving side light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

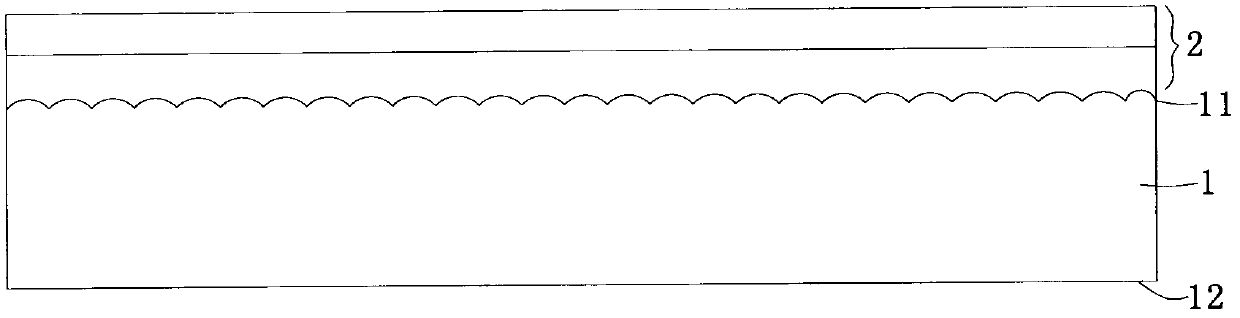

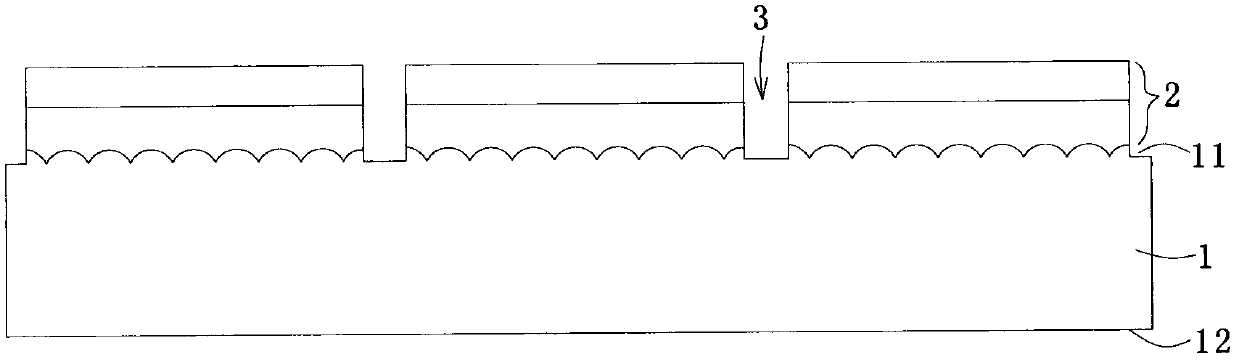

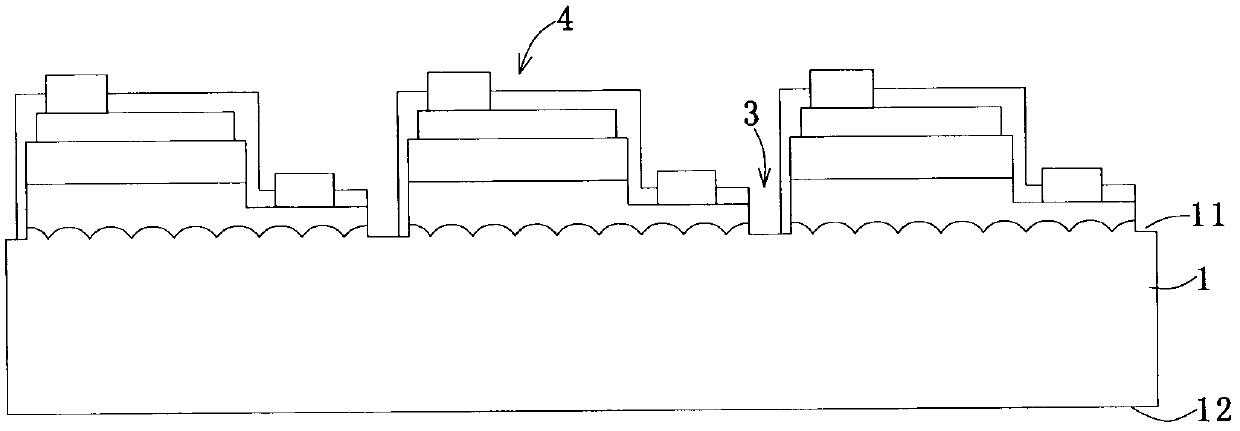

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

[0032] Such as Figure 6 , Figure 7 As shown, a stealth-cut LED chip proposed by the present invention includes a substrate 1, and a light-emitting epitaxial layer 2 and a reflective layer 5 grown on the surface of the substrate. The light-emitting epitaxial layer 2 and the reflective layer 5 are respectively located on both sides of the substrate 1 The light-emitting epitaxial layer 2 emits light to its two sides, including the light propagating away from the substrate 1 and the light propagating toward the substrate 1. A part of the light passes through the substrate 1 and reaches the reflective layer 5, and the reflective layer 5 will transmit The light passing through the substrate 1 is reflected to the light-emitting epit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com