LED encapsulation method and LED encapsulation structure encapsulated with same

A technology of LED packaging and LED chips, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of low light output efficiency of LED package structure, and achieve the effects of benefiting light output, improving light output efficiency, and reducing light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

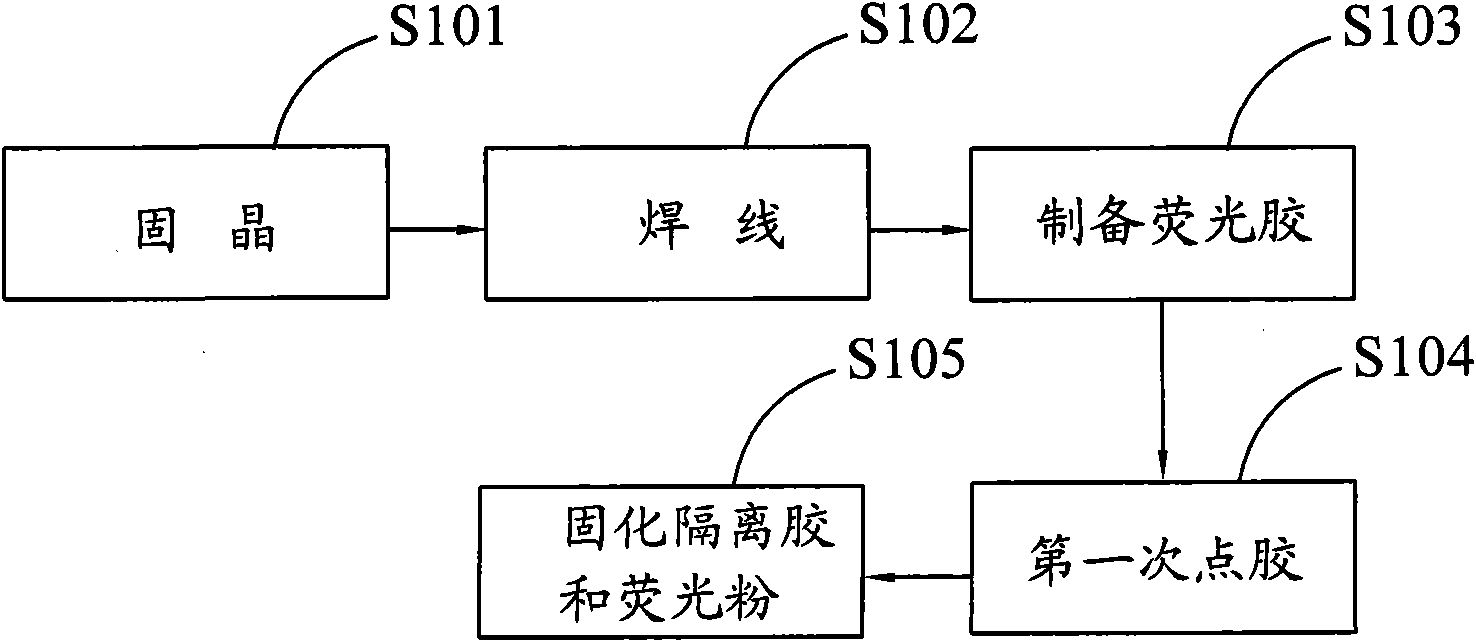

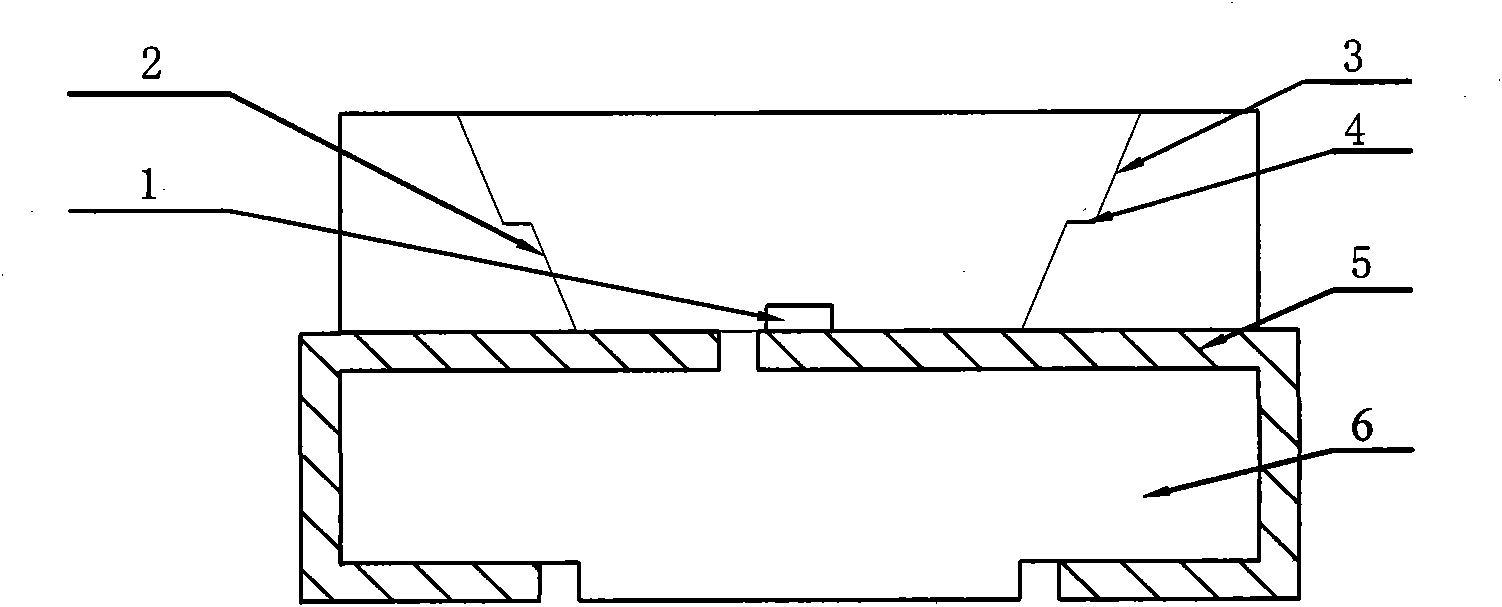

[0034] figure 1 and Figure 3 ( Figures 3a-3d ) shows a flow chart and a schematic diagram of the operation of the LED packaging method provided by the first embodiment of the present invention, and is described in detail as follows:

[0035] In step S101, the LED chip 1 is fixed on the lead frame 5 of the LED bracket, such as Figure 3a ;

[0036] In step S102, the two ends of the bonding wire 7 are respectively connected to the LED chip 1 and the lead frame 5, so that the LED chip 1 and the lead frame 5 are electrically connected, as Figure 3b ;

[0037] In step S103, evenly mix the isolation glue 9 and the fluorescent powder to prepare the fluorescent glue 8;

[0038] In step S104, the first glue dispensing is performed, and the fluorescent glue 8 is put into the reflective cup to cover the LED chip 1, such as Figure 3c ;

[0039] In step S105, the fluorescent powder and the isolation glue 9 are cured, and the LED bracket after the first glue dispensing is turned up...

Embodiment 2

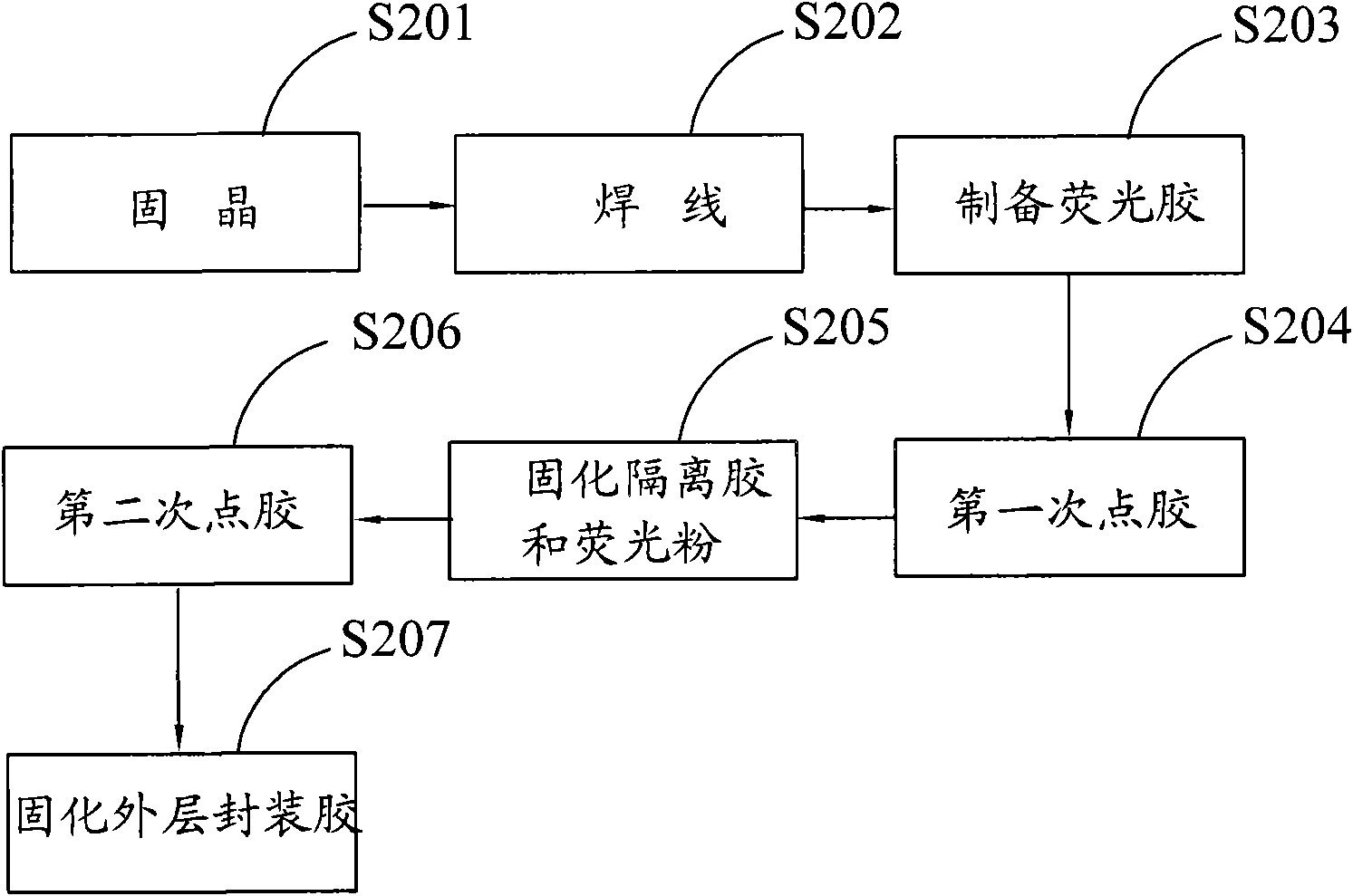

[0042] figure 2 and Figure 3 ( Figures 3a-3e ) shows a flow chart and a schematic diagram of the operation of the LED packaging method provided in the second embodiment of the present invention, which are described in detail as follows:

[0043] The embodiment of the present invention is a further optimization of the LED packaging method provided in the first embodiment above. Steps S201 to S205 are the same as steps S101 to S105 in the first embodiment above. After step S205, the following steps are added:

[0044] In step S206, after the baked LED bracket is turned over, the second dispensing is performed, such as Figure 3e .

[0045] Cover the outer layer encapsulation glue 11 on the outside of the crescent-shaped phosphor layer 10 to protect the phosphor layer 10. By selecting the insulating glue 9 and the outer layer encapsulating glue 11 with suitable bonding performance, the insulating glue 9 and the outer layer encapsulation can be made The bonding between the ad...

Embodiment 3

[0048] The embodiment of the present invention specifically sets the baking conditions in the above-mentioned embodiment 1 or embodiment 2. The time for baking the LED bracket after the first dispensing is 6 hours, and the baking temperature is 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com