Insulating and thermal conductive ablation resistant adhesive and application thereof in lightning protection

A technology of insulation, heat conduction, and ablation resistance, which is applied in adhesives, adhesive additives, epoxy resin glue, etc., can solve problems such as difficulty in meeting lightning protection requirements, decline in mechanical properties of composite materials, and far-reaching lightning protection effects. Achieve the effects of improving lightning protection, preventing conduction, and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

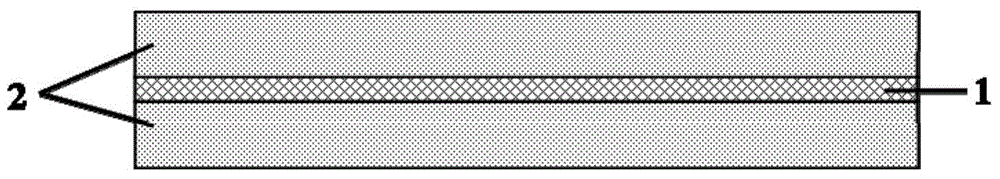

[0064] This example is used to illustrate the formulation, preparation method and application of the insulating, heat-conducting and ablation-resistant adhesive of the present invention in the direction of lightning protection.

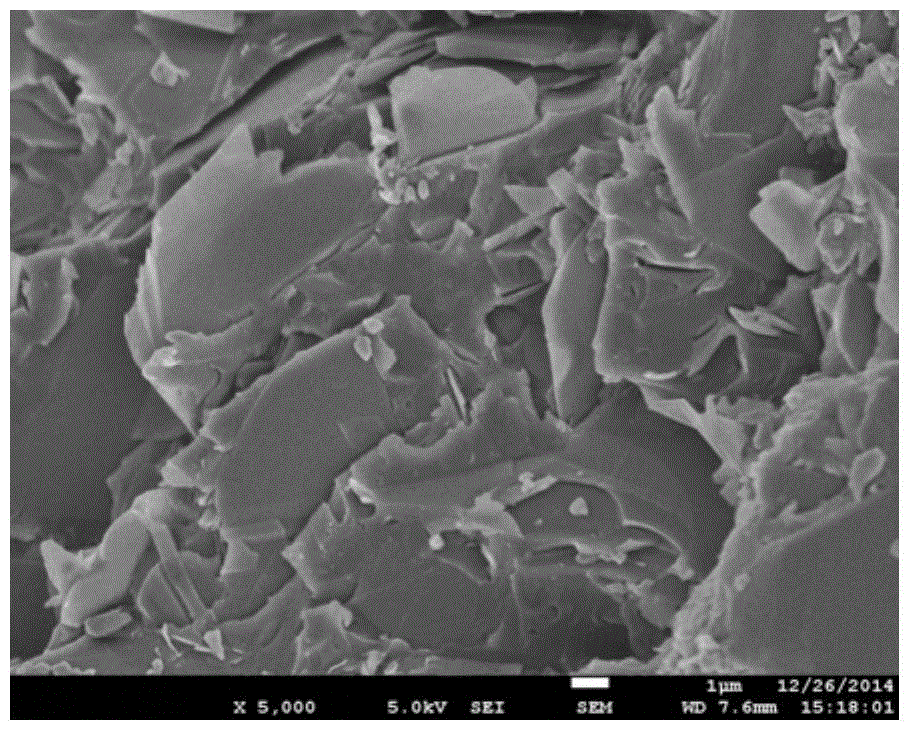

[0065] (1) Bisphenol A type pure epoxy resin E51 (Wuxi Lanxing Chemical Resin Factory) is heated to 60°C in order to remove possible crystallized resin and reduce the viscosity of the resin, add 35.5g particle size approx. Hexagonal boron nitride particles of 5 μm (Shanghai Shuitian Science and Technology Materials Co., Ltd., ST-N-003-4), stirred at 5000rpm in a high-speed mixer (DISPERMAT AE) for 1h, after stirring and mixing, the obtained mixture was passed through a three-roll mill (EXAKT 80E) grinding to obtain a uniformly dispersed masterbatch;

[0066] (2) At 50-80°C, mix the masterbatch obtained in step (1) with an acid anhydride curing agent HE600 (mixture of methyl hexahydrophthalic anhydride and N,N-dimethylbenzylamine, mass ratio 100:1) mi...

Embodiment 2-7

[0071] This example is used to illustrate the formulation, preparation method and application of the insulating, heat-conducting and ablation-resistant adhesive of the present invention in the direction of lightning protection.

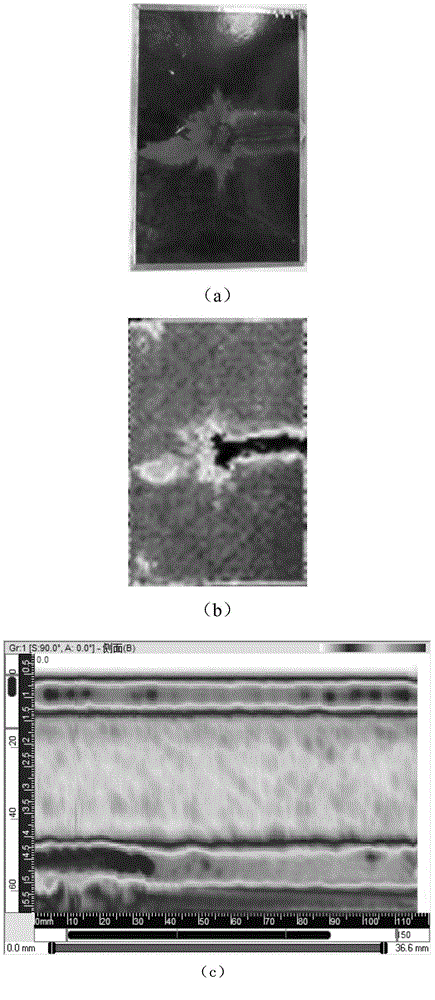

[0072] Carbon fiber composite parts for lightning tests were prepared according to the method of Example 1. The conductive films used were all multi-walled carbon nanotube conductive films with a thickness of 70 μm. The difference was that the content of epoxy resin in the adhesive was changed. , the content of boron nitride, and the thickness of the adhesive, the formula of the adhesive, the properties after curing, and the lightning protection effect statistics of the composite parts are shown in Table 1. The test pieces described in Examples 2-6 only have a large surface The wall carbon nanotube conductive film is damaged, but the interior of the carbon fiber composite part is not damaged, and the lightning protection effect is better.

[0073] The...

Embodiment 8

[0077] This example is used to illustrate the formulation, preparation method and application of the insulating, heat-conducting and ablation-resistant adhesive of the present invention in the direction of lightning protection.

[0078] (1) Heating four-functional epoxy resin 4,4'-diaminodiphenylmethane epoxy resin (MY721, Huntsman) to 60°C to remove possible crystallized resin and reduce the viscosity of the resin, to 100g of the epoxy resin Add 26.9g of alumina nanoparticles with a particle size of about 30nm (Shanghai Shuitian Science and Technology Materials Co., Ltd., ST-O-005-1), stir in a high-speed mixer (DISPERMAT AE) at 5000rpm for 1h, and mix the obtained The mixture is ground by a three-roll mill (EXAKT 80E) to obtain a uniformly dispersed masterbatch;

[0079] (2) At 80°C, mix the masterbatch obtained in step (1) with curing agent Aradur917 and accelerator DY 070 according to the stoichiometric ratio. Stir in a mixer at a speed of 2000rpm for 30min, and then remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com