Wafer processing body, temporary adhesive material for wafer processing, and method

A kind of adhesive material, temporary technology, applied in the direction of semiconductor/solid-state device manufacturing, polymer adhesive additive, film/sheet without carrier, etc., can solve the problems of cleaning and removability, difficult to apply production process, long peeling Time and other issues, to achieve good CVD resistance, shorten the bonding time, easy to crack the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~4

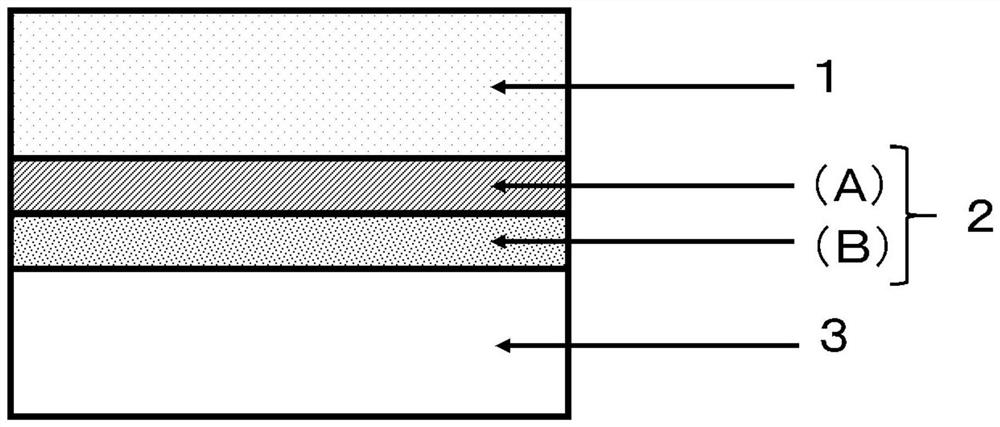

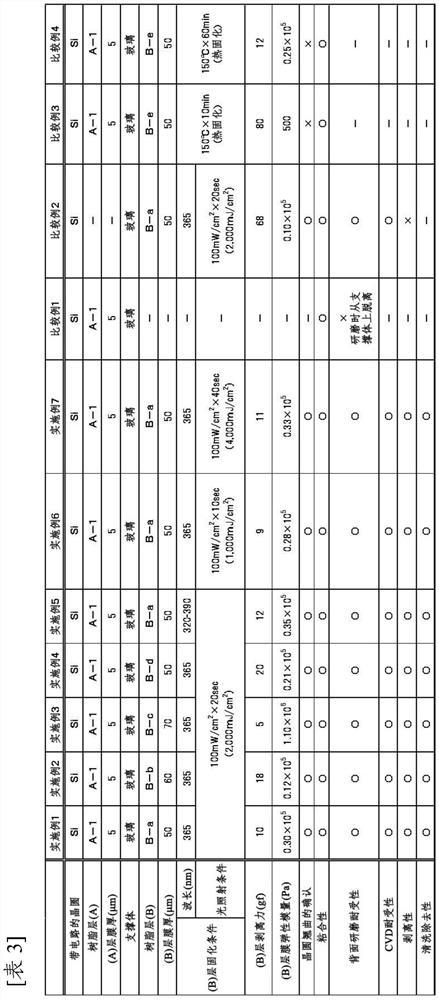

[0191] After the material (A-1) corresponding to the (A) layer was spin-coated on a silicon wafer (thickness: 725 μm) with a diameter of 200 mm and a copper pillar with a height of 10 μm and a diameter of 40 μm formed on the entire surface, the By heating at 150° C. for 5 minutes, the layer (A) was formed into a film with the film thickness shown in Table 3 on the bump formation surface of the wafer. On the other hand, a glass plate with a diameter of 200 mm (thickness: 500 μm) was used as a support, and a solution of a photocurable silicone composition corresponding to layer (B) was spin-coated on the support, and then placed on a hot plate. By heating at 70°C for 2 minutes, the layer (B) was formed on the support with the film thickness shown in Table 3. Using EVG's wafer bonding device EVG520IS, at 25°C, 10 -3 Under the conditions of below mbar and a load of 5kN, the silicon wafer with the thermoplastic resin layer (A) and the glass plate with the photocurable siloxane pol...

Embodiment 8~10

[0216] After the material (A-1) corresponding to the (A) layer was spin-coated on a silicon wafer (thickness: 725 μm) with a diameter of 200 mm and a copper pillar with a height of 10 μm and a diameter of 40 μm formed on the entire surface, the By heating at 150° C. for 5 minutes, the (A) layer was formed into a film with the film thickness shown in Table 4 on the bump formation surface of the wafer. On the other hand, a solution of a photocurable silicone composition corresponding to the (B) layer was spin-coated on a silicon wafer with a diameter of 200 mm (thickness: 500 μm) used as a support, and then heated on a hot plate at 70° C. It heated for 2 minutes, and formed (B) layer on a support body with the film thickness shown in Table 4. Next, the (B) layer was irradiated with light under the conditions shown in Table 4 using a surface irradiation type UV-LED (wavelength 365 nm) irradiator. Using EVG's wafer bonding device EVG520IS, at 40°C, 10 -3 The silicon wafer with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com