Acrylonitrile-chlorinated polyethylene-styrene resin composition and preparation method of acrylonitrile-chlorinated polyethylene-styrene resin composition

A technology of chlorinated polyethylene and styrene resin, applied in the field of resin composition and its preparation, can solve the problem that weather resistance and low temperature resistance cannot be satisfied at the same time, achieve excellent weather resistance, high low temperature impact resistance, improve rigidity and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

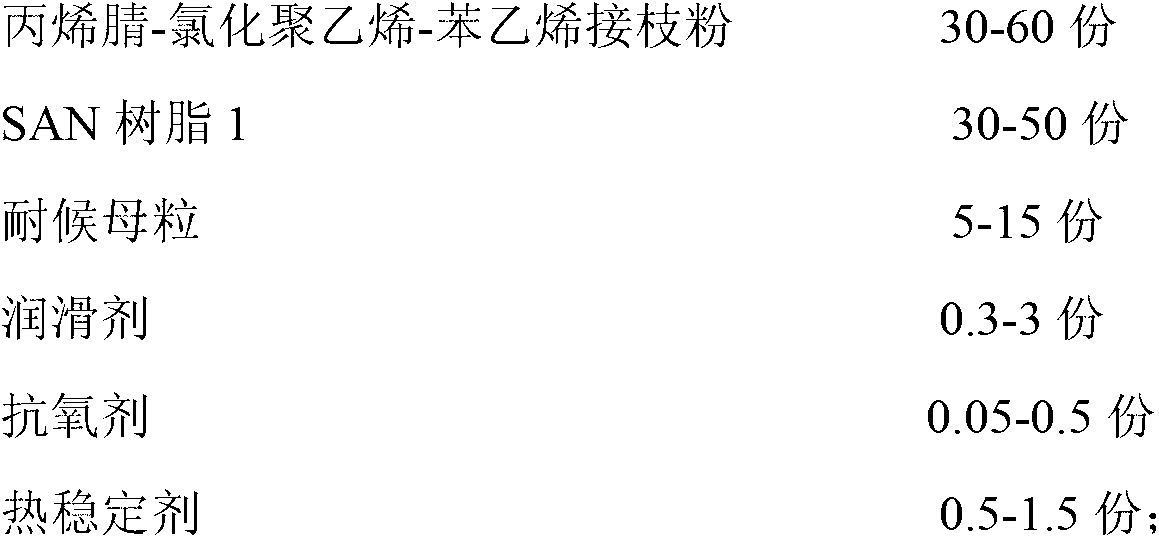

Method used

Image

Examples

Embodiment 1

[0056] Add 30Kg of SAN resin 2, 43Kg of methyl methacrylate, 10Kg of polymer containing silicone rubber, 4Kg of compatibilizer, and 3Kg of antioxidant into a high-speed mixer and stir for 20 minutes before discharging to obtain mixture A.

[0057] Add mixture A from the main feeding port of the twin-screw extruder, mix 5Kg light absorber and 5Kg light stabilizer first, then add it from the side feeding port of the twin-screw extruder, extrude and granulate to obtain weather-resistant masterbatch , the barrel temperature of the extruder is 150-200°C, and the screw speed is 180-600rpm.

[0058] Put 45Kg of ACS resin, 45Kg of SAN resin 1, 0.5Kg of lubricant, 0.3Kg of antioxidant, and 0.8Kg of heat stabilizer into a high-speed mixer, stir for 5-30 minutes, and discharge to obtain mixture B.

[0059] Add mixture B from the main feeding port of the twin-screw extruder, add 10Kg of weather-resistant masterbatch from the side feeding port of the twin-screw extruder, extrude and granul...

Embodiment 2-4

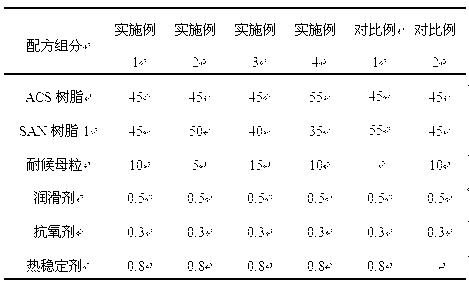

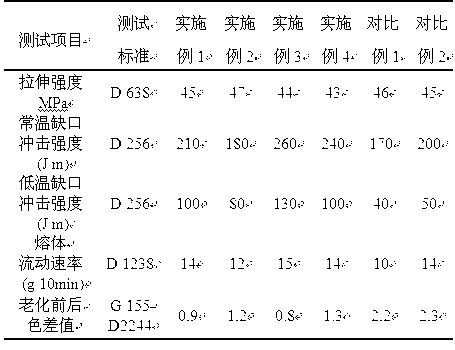

[0061] In order to better reflect the characteristics of the above-mentioned high weather-resistant acrylonitrile-chlorinated polyethylene-styrene resin composition, the present invention uses Examples 2-4, selects the same weather-resistant masterbatch as in Example 1, and compares the weather-resistant masterbatch The impact of different dosages of ACS and ACS resins on product performance, the specific material formulation is shown in Table 1, and the steps are the same as in Example 1.

Embodiment 5

[0076] Add 10Kg of SAN resin 2, 50Kg of methyl methacrylate, 15Kg of polymer containing silicone rubber, 8Kg of compatibilizer, and 3Kg of antioxidant into a high-speed mixer and stir for 20 minutes before discharging to obtain mixture A.

[0077] Add mixture A from the main feeding port of the twin-screw extruder, mix 3Kg light absorber and 6Kg light stabilizer first, then add it from the side feeding port of the twin-screw extruder, extrude and granulate to obtain weather-resistant masterbatch , the barrel temperature of the extruder is 150-200°C, and the screw speed is 180-600rpm.

[0078] Put 30Kg of ACS resin, 50Kg of SAN resin 1, 3Kg of lubricant, 0.05Kg of antioxidant, and 0.5Kg of heat stabilizer into a high-speed mixer and stir for 5-30 minutes before discharging to obtain mixture B.

[0079] Add the mixture B from the main feeding port of the twin-screw extruder, add 15Kg weather-resistant masterbatch from the side feeding port of the twin-screw extruder, extrude and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com