Liquid crystal aligning agent and method for forming liquid crystal alignment films

A technology of liquid crystal alignment agent and polymer, which is applied in the directions of instruments, optics, nonlinear optics, etc., and can solve problems such as thermal decomposition of side chains that cannot be ruled out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

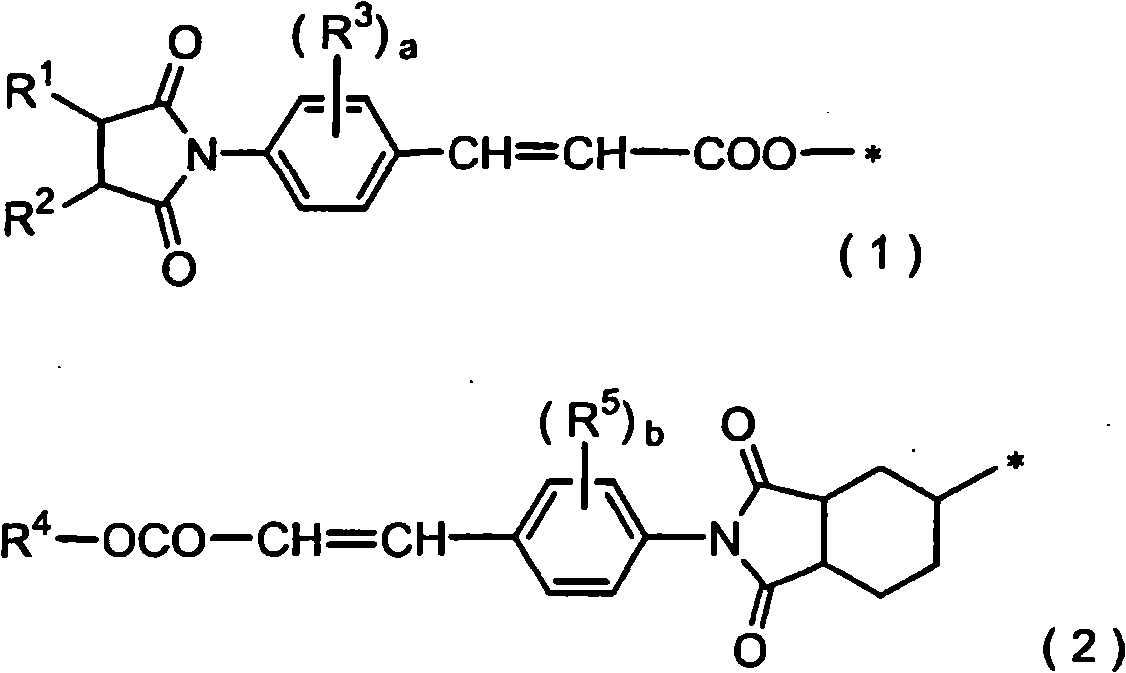

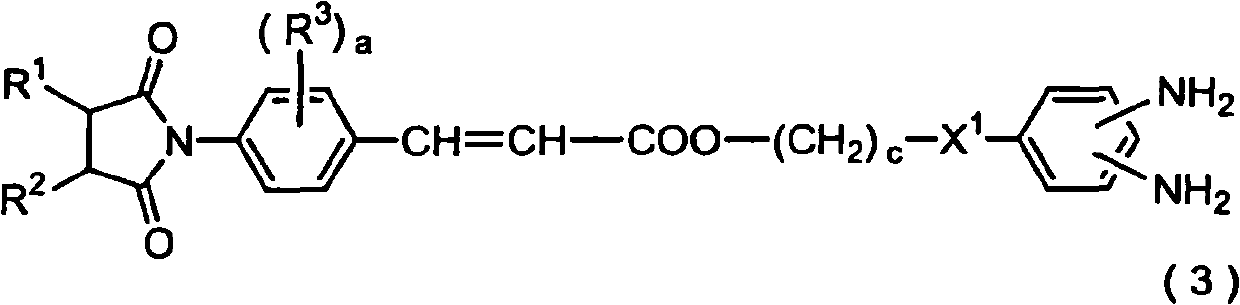

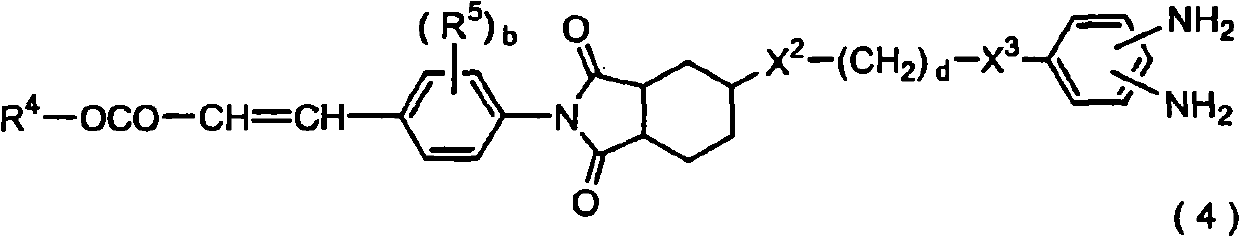

Image

Examples

Embodiment 1

[0134] Example 1 (synthesis of compound (3A-1))

[0135] Compound (3A-1) was synthesized according to the following Synthetic Scheme 1.

[0136]

[0137] Synthetic route 1

[0138] (Synthesis of compound (3A-1a))

[0139] In a 1L eggplant-shaped flask with a reflux condenser, a nitrogen inlet tube and a Dean-Stark tube, add 72g of decylsuccinic anhydride, 49g of 4-aminocinnamic acid, 70mL of triethylamine, 500mL of toluene and 200mL of tetrahydrofuran, and reflux for 36 hours for the reaction. After the reaction, the reaction mixture was washed with dilute hydrochloric acid and water in sequence, and the organic layer was dried with magnesium sulfate, concentrated, and recrystallized from a mixed solvent of ethanol and tetrahydrofuran to obtain 72 g of white crystals of compound (3A-1a) (purity 99%).

[0140] (Synthesis of compound (3A-1b))

[0141] In a 500mL three-neck flask with a nitrogen inlet tube and a thermometer, add 19g of compound (3A-1a), 11g of 3,5-dinitr...

Embodiment 2

[0144] Example 2 (synthesis of compound (3A-2))

[0145] Compound (3A-2) was synthesized according to Synthetic Scheme 2 below.

[0146]

[0147] Synthetic route 2

[0148] (Synthesis of compound (3A-2a))

[0149] Into a 200 mL eggplant-shaped flask equipped with a reflux condenser, 19 g of compound (3A-1a), 0.1 g of N,N-dimethylformamide and 100 mL of thionyl chloride were added, and reacted at 80° C. for 1 hour. After the reaction was over, after distilling off thionyl chloride from the reaction mixture under reduced pressure, 200 mL of dichloromethane was added to the residue, the organic layer was washed with water, and after drying with magnesium sulfate, dichloromethane was distilled off under reduced pressure, and 200 mL of tetrahydrofuran (THF) was added. This was referred to as "reaction solution 1").

[0150] On the other hand, 9.2 g of 2,4-dinitrophenol, 14 g of potassium carbonate, 0.48 g of tetrabutylammonium, and 100 mL of water were added to a 500 mL thr...

Embodiment 3

[0153] Embodiment 3 (synthesis of compound (3B-1))

[0154] Compound (3B-1) was synthesized according to the following Synthetic Scheme 3.

[0155]

[0156] Synthetic route 3

[0157] (Synthesis of compound (3B-1a))

[0158] In a 2L eggplant-shaped flask with a reflux condenser, add 198g of 1,2,4-cyclohexanetrianhydride, 500mL of thionyl chloride and 2mL of N,N-dimethylformamide, and reflux at 80°C The reaction was carried out for 1 hour. After the reaction, thionyl chloride was distilled off under reduced pressure, dichloromethane was added to the residue, the organic layer was washed successively with saturated aqueous sodium bicarbonate and water, dried over magnesium sulfate, concentrated, dried and solidified, and then 500 mL of tetrahydrofuran was added.

[0159] On the other hand, in a 3L three-neck flask equipped with a dropping funnel, a thermometer and a nitrogen inlet tube, add 178g of 4,4-5,5,5-pentafluoropentanol, 160mL of pyridine and 1.5L of tetrahydrofu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com