Liquid crystal aligning agent, forming liquid crystal aligning film, and liquid crystal display unit

A technology of liquid crystal aligning agent and polyorganosiloxane, which is applied in liquid crystal materials, chemical instruments and methods, optics and other directions to achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example ES1

[0260] In the reaction vessel equipped with stirrer, thermometer, dropping funnel and reflux condenser, add 2-(3,4-epoxycyclohexyl) ethyltrimethoxysilane 100.0g, methyl isobutyl ketone 500g and 10.0 g of triethylamine were mixed at room temperature.

[0261] Then, after adding 100 g of deionized water dropwise through the dropping funnel over 30 minutes, it was allowed to react at 80° C. for 6 hours while mixing under reflux. After the reaction, the organic layer was taken out, washed with 0.2% by weight of ammonium nitrate aqueous solution until the washed water was neutral, and the solvent and water were distilled off under reduced pressure to obtain polyorganosiloxane with epoxy groups. Alkanes (ES-1) viscous transparent liquid.

[0262] The polyorganosiloxane with epoxy group is carried out 1 In the H-NMR analysis, a peak due to the epoxy group of theoretical intensity was obtained around chemical shift (δ) = 3.2 ppm, and it was confirmed that no side reaction of the epo...

Synthetic example ES2

[0264] Synthesis example ES2~3

[0265] Viscous transparent liquids of epoxy group-containing polyorganosiloxanes (ES-2) and (ES-3) were obtained in the same manner as in Synthesis Example 1, except that the raw materials charged were as shown in Table 1.

[0266] The Mw and epoxy equivalent weight of these polyorganosiloxanes having epoxy groups are listed in Table 1.

[0267] In addition, in Table 1, the abbreviations of the raw material silane compounds have the following meanings, respectively.

[0268] ECETS: 2-(3,4-Epoxycyclohexyl)ethyltrimethoxysilane

[0269] MTMS: Methyltrimethoxysilane

[0270] PTMS: Phenyltrimethoxysilane

[0271] Table 1

[0272]

[0273]

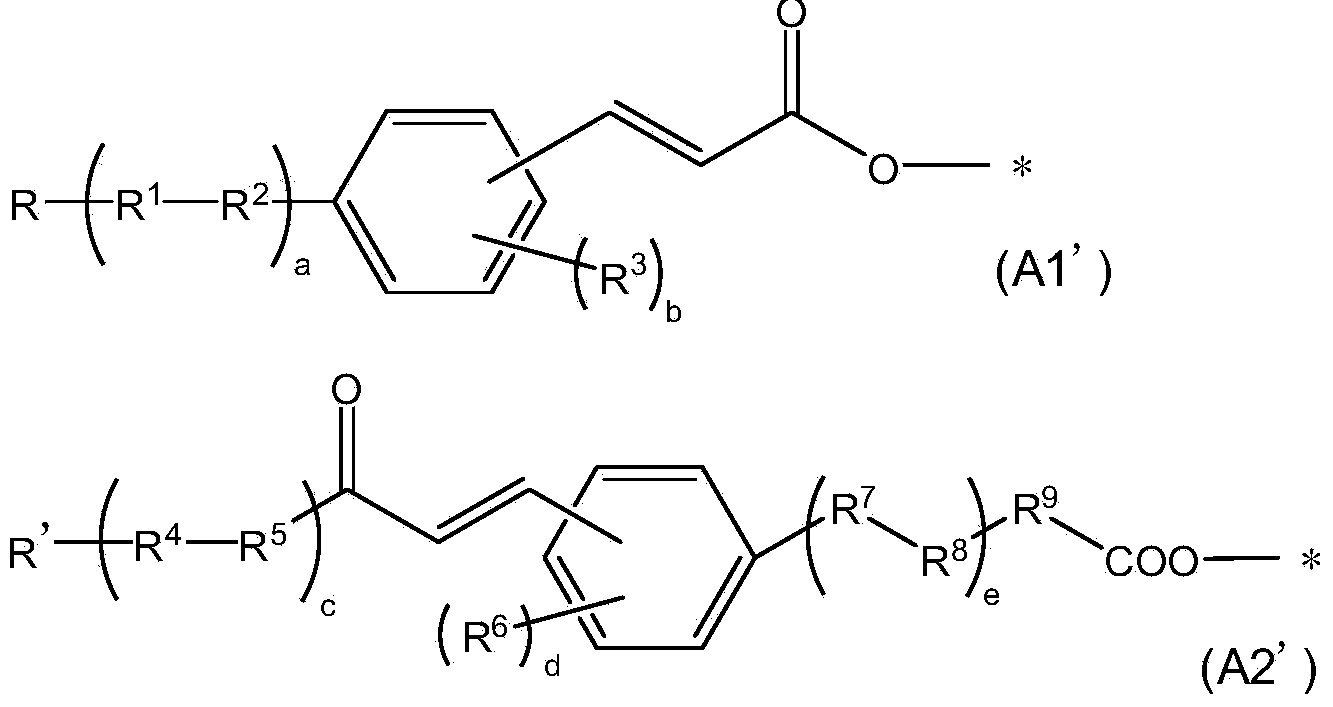

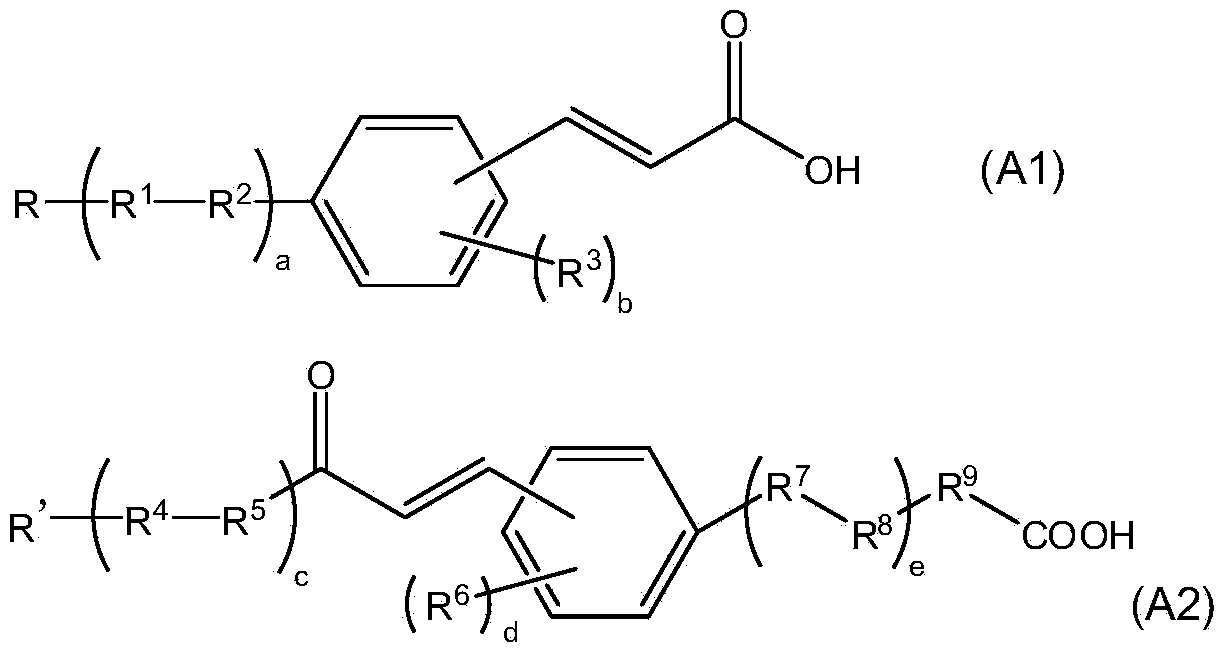

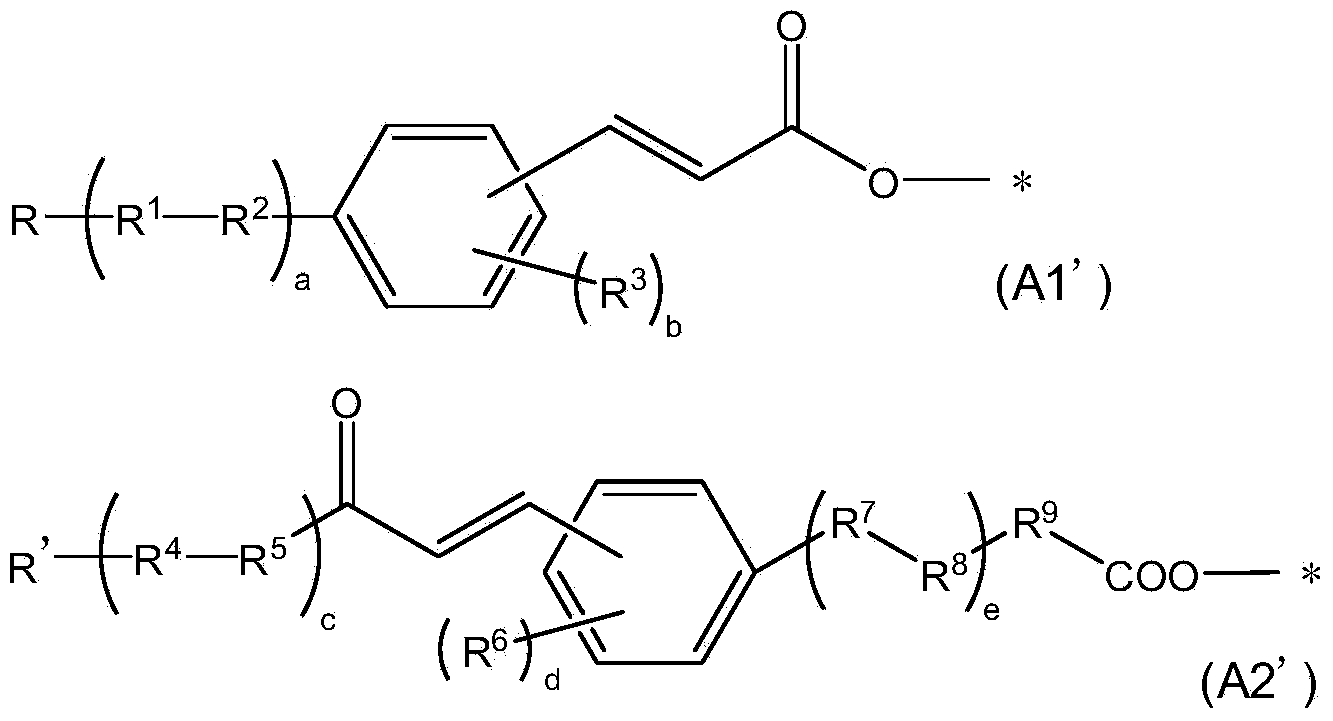

[0274] As described in the following synthesis examples A1-1 to A1-4, compounds represented by the following formulas (A1-1) to (A1-4) (hereinafter respectively referred to as "compound (A1-1)", "compound (A1-2)", "Compound (A1-3)", and "Compound (A1-4)").

[0275]

Synthetic example A1-1

[0277] In a 500ml three-necked flask equipped with a condenser, add 20g of 4-bromodiphenyl ether, 0.18g of palladium acetate, 0.98g of tris(2-tolyl)phosphine, 32.4g of triethylamine and 135ml of dimethylacetamide and mixed to form a solution. Then, 7 g of acrylic acid was added to the above solution with a syringe and stirred, and then stirred at 120° C. for 3 hours to perform a reaction. After confirming the completion of the reaction by thin layer chromatography (TLC), the reaction solution was cooled to room temperature. After filtering the insoluble matter, the filtrate was poured into 300 ml of 1N hydrochloric acid, and the precipitate was recovered. This precipitate was recrystallized in a mixed solvent of ethyl acetate and hexane (ethyl acetate:hexane=1:1 (volume ratio)), to obtain 8.4 g of compound (A1-1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com