Open-cell type apparatus for preparing sodium hypochlorite

A sodium hypochlorite, open type technology, applied in the direction of hypochlorous acid, hypochlorite, halogen oxides/oxyacids, etc., can solve problems such as the reduction of effective chlorine concentration, maintain the concentration, inhibit the generation of oxygen, and improve electrolysis. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

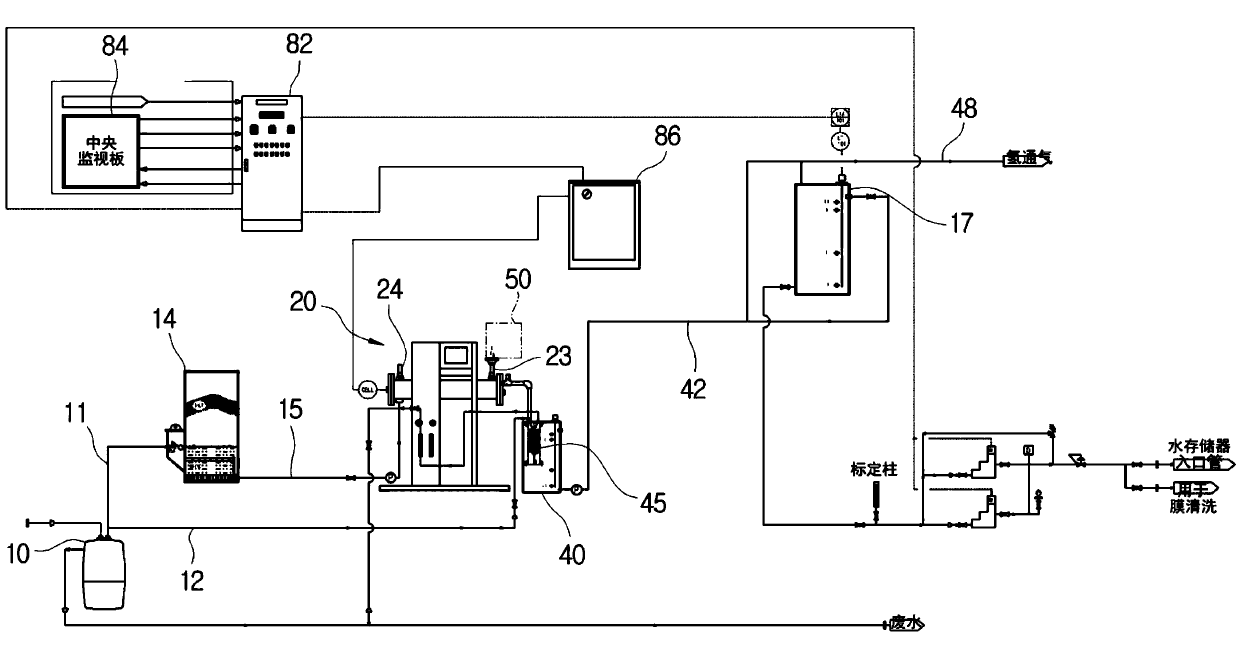

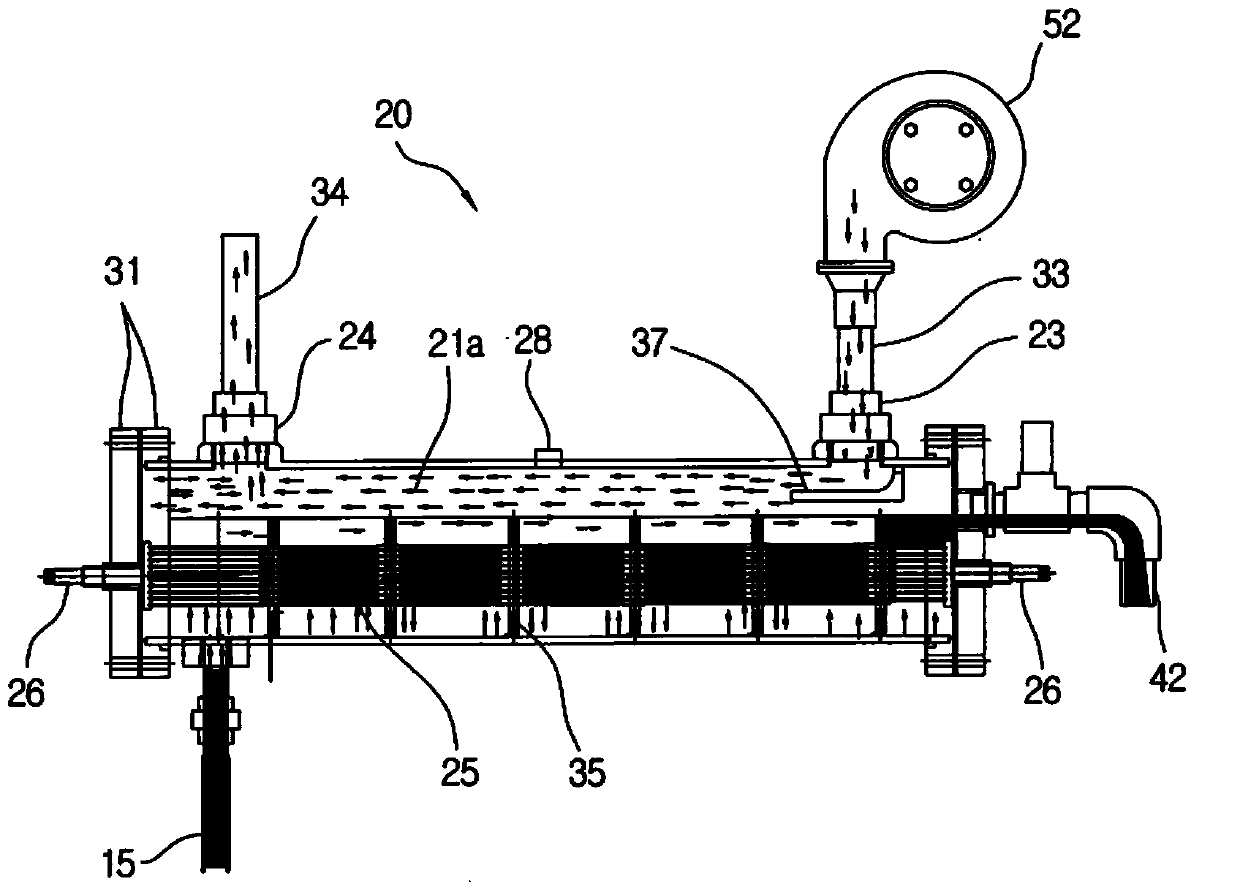

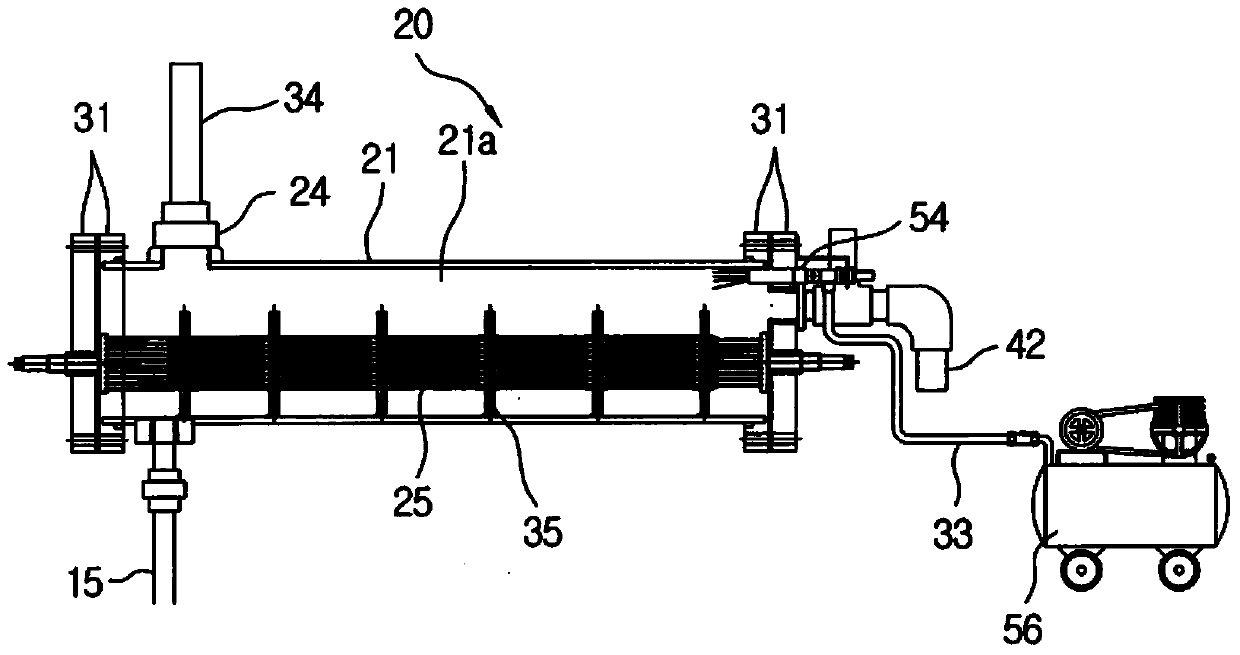

[0027] Hereinafter, specific embodiments of the present invention will be described with reference to the accompanying drawings.

[0028] The apparatus for producing sodium hypochlorite according to the present invention employs electrolysis using soft water and sodium. When using conventional manufacturing equipment, due to the heat generated during the electrolysis process, the temperature of the produced sodium hypochlorite rises to 40°C to 50°C, which is 25°C to 35°C higher than that of light brine. This high temperature reduces the concentration of available chlorine and thus hinders the formation of high concentrations of sodium hypochlorite. In view of such circumstances, the object of the present invention is to implement a technique for uninterrupted production of high-concentration sodium hypochlorite by performing electrolysis at a controlled temperature in a manner using an open-type device without a membrane.

[0029] According to the present invention, the sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com